-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2017 POTD Thread Archive

- Thread starter jpfabricator

- Start date

- Joined

- Nov 24, 2014

- Messages

- 3,196

WMello,

Your collet chuck adaptor looks great.

Usually we have to ask for pictures but this time I need a few words.

What is the spindle nose type/size on your lathe? What spindle nose type/size does the collet chuck fit?

Your collet chuck adaptor looks great.

Usually we have to ask for pictures but this time I need a few words.

What is the spindle nose type/size on your lathe? What spindle nose type/size does the collet chuck fit?

W

WMello

Forum Guest

Register Today

Hi Extropic, thank you.

The lathe is a PM1030 from Precision Matthews, and the spindle is the standard one. I don't know the type name.

The other end is to fit a ER32 adapter I've got a long time ago for the mini-lathe.; like this one http://littlemachineshop.com/products/product_view.php?ProductID=2532

Basically, the adapter is "PM1030 to mini-lathe 7x12".

If you need/want, I can post the drawing. (this evening/tomorrow, as the file is at home)

Wagner

The lathe is a PM1030 from Precision Matthews, and the spindle is the standard one. I don't know the type name.

The other end is to fit a ER32 adapter I've got a long time ago for the mini-lathe.; like this one http://littlemachineshop.com/products/product_view.php?ProductID=2532

Basically, the adapter is "PM1030 to mini-lathe 7x12".

If you need/want, I can post the drawing. (this evening/tomorrow, as the file is at home)

Wagner

to improve your chuck dead center start off with a shoulder on the piece of stock so that it does not slide back in the 3 jaw chuck. this extra step while it may take some extra time is a great safety step. and remember that this center tool can be used over and over. just chuck it up and remove enough material each time to do your job. a center like this can last for years bill

- Joined

- Dec 22, 2015

- Messages

- 561

to improve your chuck dead center start off with a shoulder on the piece of stock so that it does not slide back in the 3 jaw chuck. this extra step while it may take some extra time is a great safety step. and remember that this center tool can be used over and over. just chuck it up and remove enough material each time to do your job. a center like this can last for years bill

The shoulder idea is a good one and thanks for the tip. After looking at the pic I'm a bit concerned that having such a small contact area, so high on one of the chuck jaws, would cause excessive strain on the jaw. Maybe next time I should use the face plate instead of the 3 jaw. I was just being lazy and didn't want to go through the extra steps of switching to the faceplate.

- Joined

- Jan 20, 2016

- Messages

- 1,011

For the last few days I've been working on converting my XS650 project bike engine from points ignition to a junkyard electronic ignition system using information I found on the XS650.com site. I waited for a warm day and went out our local Pick & Pull auto wrecker and found a 79 Toyota Celica and removed it's distributor ($25).

That's pretty fricking ingenious not to mention the nice quality workmanship.

- Joined

- Jun 12, 2014

- Messages

- 4,823

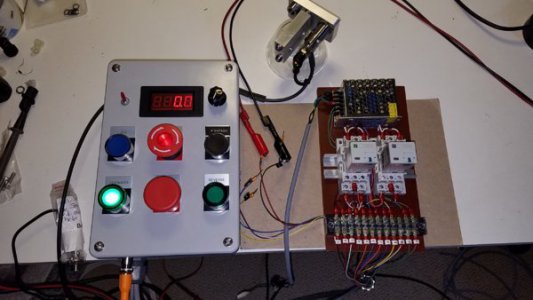

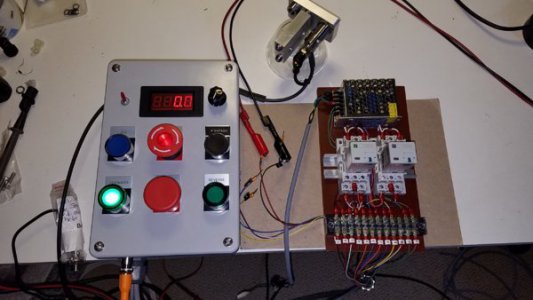

Finished up on a unique VFD control system with a proximity sensor for a Jet 1024. Since there is no spindle switch on this lathe, I incorporated all the controls into a single pod that will mounted on the headstock side. This includes direction, stop, E-Stop, speed control, braking rate speeds, proximity bypass switch and RPM meter with separate magnetic pickup. The switch control cabinet is 6" x 9" x 3" deep so the switches just fit as the lighted ones are 2.7" deep behind the panel. The box/configuration would also be applicable to a mill setup. The control system is driven by the WJ200 24VDC power supply, there is also a 12VDC power supply to power the tachometer, and possibly a LED light. The proximity sensor systems plugs in the switch control box, the relay control/12VDC supply will mount in the VFD enclosure making it a 2 box system. The switch direction controls/stop are all momentary switches with latching relays, the stop or opposite direction buttons break the relay latch. The relays are cross wired so only one can be energized at a time and the jog only operates when the spindle is stopped. An interesting one off project, but too many hours developing and building these things. Still nice to see them working and the pleasure it gives others using them. So it goes.

- Joined

- Nov 24, 2014

- Messages

- 3,196

MKSJ,

If you prepare a data package (comprehensive "how too") I would be a buyer. I expect many others would also.

In the meantime, I'll congratulate you for designing, building and integrating the controls.

A covetous observer.

If you prepare a data package (comprehensive "how too") I would be a buyer. I expect many others would also.

In the meantime, I'll congratulate you for designing, building and integrating the controls.

A covetous observer.

- Joined

- Nov 24, 2014

- Messages

- 3,196

Hi Extropic, thank you.

The lathe is a PM1030 from Precision Matthews, and the spindle is the standard one. I don't know the type name.

The other end is to fit a ER32 adapter I've got a long time ago for the mini-lathe.; like this one http://littlemachineshop.com/products/product_view.php?ProductID=2532

Basically, the adapter is "PM1030 to mini-lathe 7x12".

If you need/want, I can post the drawing. (this evening/tomorrow, as the file is at home)

Wagner

Thanks for the reply. I looked up the published specs for both lathes. The PM1030 says "Direct Mount" but doesn't specify a standard. Similar info on the 7x12.

No need to publish the adaptor drawing for me but may be useful for somebody else.

Thanks again. Nice job.