-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2018 POTD Thread Archive

- Thread starter 2volts

- Start date

- Joined

- Sep 2, 2013

- Messages

- 5,100

Great save on the snow blower Brino. Most would have chunked that on scrap pile. While the weld may not be pretty, it did the trick, and oil impregnated, cheap castings can be really tough to get a good weld on. Mike

- Joined

- Feb 1, 2015

- Messages

- 9,608

Nice save!

Other obligations keep me from doing much machining most days, but I do what I can, when I can.[/QUOTE]

I know the feeling. I spent the whole day cleaning and lubing my machines, putting tools and fixtures away and just generally cleaning the shop. I have a habit of using all my available time working on a project and just walking away without cleaning or putting things away. It gets out of hand at some point. Oh yeah...I also ground one tool blank for internal threading....and then left the stones laying on the bench after I finished honing it. LOL

I know the feeling. I spent the whole day cleaning and lubing my machines, putting tools and fixtures away and just generally cleaning the shop. I have a habit of using all my available time working on a project and just walking away without cleaning or putting things away. It gets out of hand at some point. Oh yeah...I also ground one tool blank for internal threading....and then left the stones laying on the bench after I finished honing it. LOL

- Joined

- Dec 6, 2015

- Messages

- 809

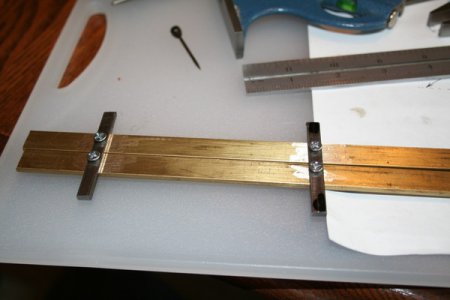

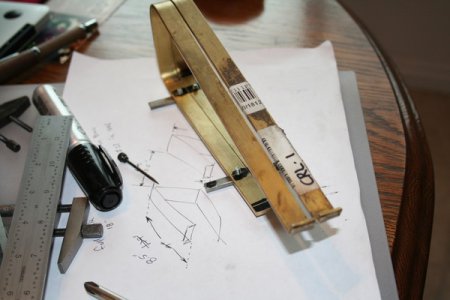

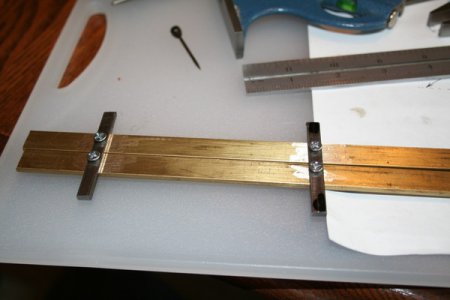

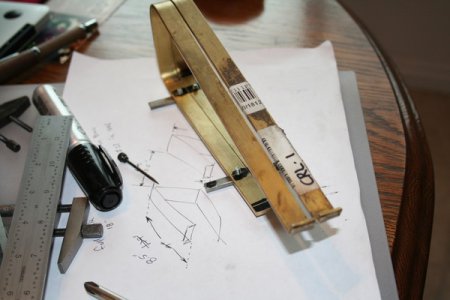

I realized long ago that (with my tendency to explore and learn new things) I should not be left unsupervised with tools, materials, and time. This time my right brain said, "laptop stand?" and my left argued with "why not in brass? That would look cool!" So in a day, it was two "bars" of 1/8"x1/2" brass stock, hex rod, and rounds. First experiment was trying to bend the two bars identically. Started trying to use machinist clamps but wasn't stable enough, then drilled two holes and tapped them with a crossmember to keep them tight. I'd say it worked pretty nicely (especially since I had the rubber for the feet already on hand).

Works pretty good!

Works pretty good!

F

Firestopper

Forum Guest

Register Today

Your Mac will run cooler. Mine runs warm when used on dining table (wood).

Looks elegant too.

Looks elegant too.

Nicely presented repair brino.

The damage reminded me of my Matchless twin motorcycle (I was a foolish youth) they had a reputation for the big ends letting go. Mine did that while I was overtaking a truck, BIG bang and exploded crankcase, much smoke and locked rear wheel, slightly elevated heart rate. Crank case wasn't repairable as most of it was missing.

I can't see from your photos if the alloy conrod runs direct on the crank pin or if there is a bearing shell. I learned from working on 2 stroke engines, which were frequently seized solid, that Hydrochloric acid would dissolve smeared alloy from the iron cylinders, should work on crank pins, needs a good wash in soda afterwards. Wouldn't work on whitemetal shells though.

Dredb

The damage reminded me of my Matchless twin motorcycle (I was a foolish youth) they had a reputation for the big ends letting go. Mine did that while I was overtaking a truck, BIG bang and exploded crankcase, much smoke and locked rear wheel, slightly elevated heart rate. Crank case wasn't repairable as most of it was missing.

I can't see from your photos if the alloy conrod runs direct on the crank pin or if there is a bearing shell. I learned from working on 2 stroke engines, which were frequently seized solid, that Hydrochloric acid would dissolve smeared alloy from the iron cylinders, should work on crank pins, needs a good wash in soda afterwards. Wouldn't work on whitemetal shells though.

Dredb