-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2021 POTD Thread Archive

- Thread starter Gaffer

- Start date

- Joined

- Dec 15, 2018

- Messages

- 785

Thanks guys !!

Its not a practical method of framing a building, but they feel solid when you walk into one. And they're fun to whittle out. Just hope it all fits together on assembly day.

Should have the footings in this week if Kelly shows up with an excavator and a load of gravel. I have no doubt he will.

Greg

Its not a practical method of framing a building, but they feel solid when you walk into one. And they're fun to whittle out. Just hope it all fits together on assembly day.

Should have the footings in this week if Kelly shows up with an excavator and a load of gravel. I have no doubt he will.

Greg

- Joined

- Dec 18, 2019

- Messages

- 6,464

I'm just glad that I was able to make a mess, swarf, that is. Been out of the shop for almost 4 weeks. Vacation for a week - which was fun, and being sick for the last 18 days.  Seems I caught my grandson's daycare "crud". About a week ago, near the peak of the symptoms, I thought maybe it was Covid. Got tested, and thankfully it wasn't. Been a weird and slow recovery. Still not quite back to myself yet.

Seems I caught my grandson's daycare "crud". About a week ago, near the peak of the symptoms, I thought maybe it was Covid. Got tested, and thankfully it wasn't. Been a weird and slow recovery. Still not quite back to myself yet.

So I'm happy to make it into the shop to do something today. Did some boring using my recently purchased Circle Machine QCBI 1/2" boring bar. Workpiece is 1.5" 304 stainless. Previously I had knurled it. Today I hogged it out using a 1/2" cobalt drill and a 41/64" MT2 drill. Then I started boring. Took me a while to get the hang of things, thing was chattering. And that chipped the insert twice. Eventually figured out the toolpost nut wasn't tightened! Seems that I had moved it 4 weeks ago and hadn't fully tightened it. Tightening it another 1/4 turn quieted it down a lot. Now you can hear the steel sort of hissing as it peels off the cutter. The bore is almost to ID now. After I enlarge the ID by 0.060", the next step will be to flatten out the inside of the bottom.

Then I will do an inside thread for a cap. Haven't decided the pitch. Have about 1/4" of threads, so can't go too coarse. Maybe 20 TPI?

So it's good to do things again

Seems I caught my grandson's daycare "crud". About a week ago, near the peak of the symptoms, I thought maybe it was Covid. Got tested, and thankfully it wasn't. Been a weird and slow recovery. Still not quite back to myself yet.

Seems I caught my grandson's daycare "crud". About a week ago, near the peak of the symptoms, I thought maybe it was Covid. Got tested, and thankfully it wasn't. Been a weird and slow recovery. Still not quite back to myself yet. So I'm happy to make it into the shop to do something today. Did some boring using my recently purchased Circle Machine QCBI 1/2" boring bar. Workpiece is 1.5" 304 stainless. Previously I had knurled it. Today I hogged it out using a 1/2" cobalt drill and a 41/64" MT2 drill. Then I started boring. Took me a while to get the hang of things, thing was chattering. And that chipped the insert twice. Eventually figured out the toolpost nut wasn't tightened! Seems that I had moved it 4 weeks ago and hadn't fully tightened it. Tightening it another 1/4 turn quieted it down a lot. Now you can hear the steel sort of hissing as it peels off the cutter. The bore is almost to ID now. After I enlarge the ID by 0.060", the next step will be to flatten out the inside of the bottom.

Then I will do an inside thread for a cap. Haven't decided the pitch. Have about 1/4" of threads, so can't go too coarse. Maybe 20 TPI?

So it's good to do things again

I recently got a bunch of bushings that appear to be oil-lite in a box with all of the electrical brushes. I had an empty organizer so i figured that will do just fine. I then also had a visitor that I was tempted to get rid of but i then could not find him.

Attachments

- Joined

- Oct 28, 2020

- Messages

- 528

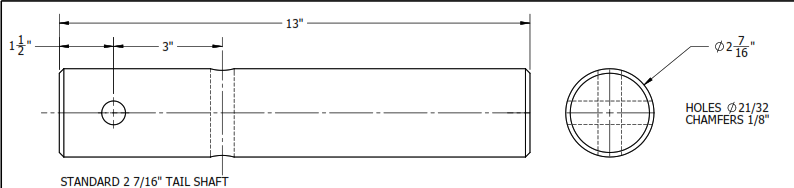

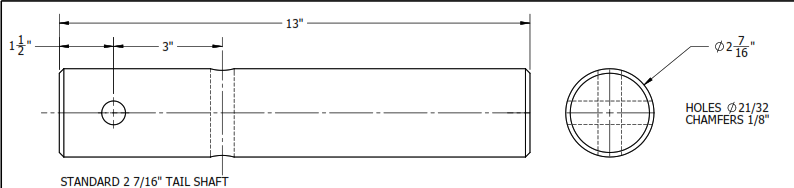

Today in my little shop I got started on a batch of screw conveyor tail shafts. This is something i keep in stock and my customer buys one or two a month. The tail shafts are 2 7/16" diameter x 13" long. They weight about 17 lbs and are from precision ground 1045 steel. I make them up in batches of eight.

I turned up a close fitting collar for the steady rest to ride on, so that there is no danger of marring the precision ground surface. The collar has brass set screws.

I turned up a close fitting collar for the steady rest to ride on, so that there is no danger of marring the precision ground surface. The collar has brass set screws.

- Joined

- Feb 17, 2013

- Messages

- 4,406

@Brento - Back when I lived in Oregon, there were lots of spider webs in various places in my garage/shop. One in particular made her home behind my drill press. Over the course of one year, I'd occasionally capture a moth or other small bug and drop it into her web. Win-win. She got to eat well, I was entertained, and the pest population got slightly smaller.

- Joined

- Dec 18, 2019

- Messages

- 6,464

Hope no one has arachnophobia! What a great picture.

Now that was just rude lolOK. I don't dislike them, but I can appreciate your point of view.

... and then, there's the Cookie Monster ...

View attachment 379351