-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2021 POTD Thread Archive

- Thread starter Gaffer

- Start date

- Joined

- Dec 22, 2014

- Messages

- 201

Low speed finish turner...

- Joined

- Sep 22, 2019

- Messages

- 940

- Joined

- Jan 11, 2018

- Messages

- 308

- Joined

- Nov 24, 2014

- Messages

- 3,159

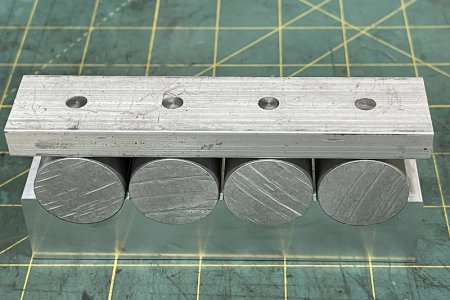

I have about 150x 1" x 1" aluminum rounds that I need to cross drill and tap. I've already drilled them on my CNC mill, but it isn't set up for tapping. Today I made this jig to hold 4 pieces in my drill press vise and a tool to set them vertically into the jig.

Is there a plan for how your vice is going to grip all four parts at the same time?

- Joined

- Jan 11, 2018

- Messages

- 308

Is there a plan for how your vice is going to grip all four parts at the same time?

They were all cut to the same length on my lathe. If I have to I’ll throw a chunk of plywood between the rounds and one side of the vise to help equalize the clamping pressure.

- Joined

- Jul 14, 2017

- Messages

- 2,447

New day new problem, the clutch cable on my 605 that i fix few weeks ago snapped again. I was expecting this to happen but it should lasted a bit more. Now all the shops are closed and the new replacement i've order is still in france. I'll be driving the 607 for few days, till i can get one made or the OEM arrives.

- Joined

- Dec 6, 2015

- Messages

- 809

One of those hobbies I've had for my entire adult life is making fishing rods, and they're always coated with epoxy. I use a rotisserie motor to turn them. They're slow motors but fast enough to keep the finish level as it sets. I run the rods overnight, more or less, and the epoxy sets up enough to not run any more.

The drawback for your use is that it can only handle one rod at a time, while yours holds eight. I've never needed to be concerned about throughput since I build one rod at a time for my wife or me. One rod every few years.

So, how do you do yours in comparison?