- Joined

- Jul 14, 2017

- Messages

- 2,451

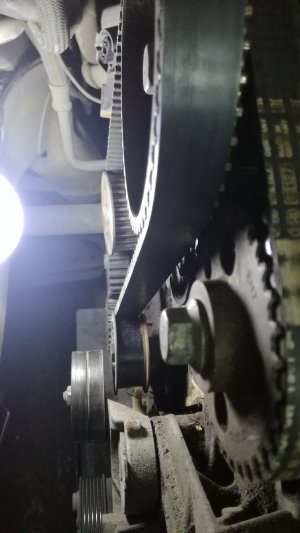

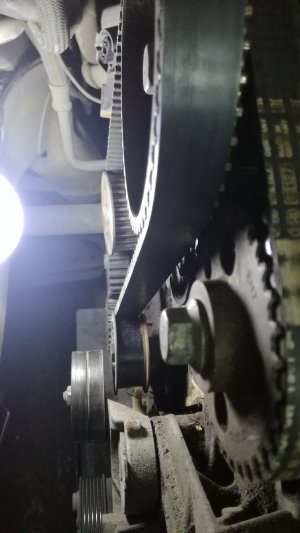

Today i got an early start in the big garage, unbolted the intake manifold for the 206, began removing the cracked hoses, and my brother called. White elephant No:1 now is losing coolant, told him to leave it in the small garage i'll look at it on the inspection pit. Went there left the 206 for another day, and the engine is sounding awful, like a coffee grinder, went under it seen rusty water coming from the timing cover, i know its going to be a long day. Looked at the coolant and it's straight water no antifreeze, he has no idea where is the antifreeze. It leaks wore when is running so i know it's the water pump, i did send him to go and buy a new one in the No:2 freshly fixed. Its seams the two white cars are competing for attention. I began the terdown, the water pump is driven by the timing belt. removed the inteke, engine mount, accessory belt, couple of the pulleys, cover and i can see the water pump pulley is sideways and the belt is loos. Remove the belt, pump, had to restart the tensioner, and it was a mess, my brother come back with the right pump, swap it reassembled everything, new antifreeze, bleed the cooling system and its was done.