- Joined

- Apr 5, 2013

- Messages

- 391

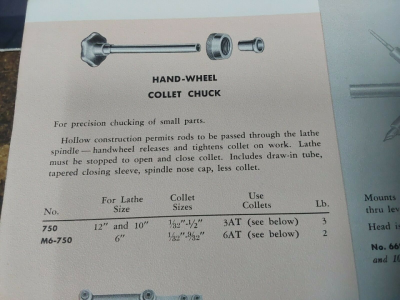

It is tiny , stock collets 9/32 max - 1/32 smallest . I have a MT set up that is 1/2 max - 1/8 smallest . So why would I want the 6 AT ? Aside from the fact that you can pass a rod through the spindle , the main thing this was original Atlas tooling and that was the draw for me . Be it pretty much useless but it's mine and I love it . I have a few questions that I know you guy's can help with . My machine is an Atlas / Craftsman 101.07301 six inch swing , that's the one with back gear and spindle bushings not Timken bearings .

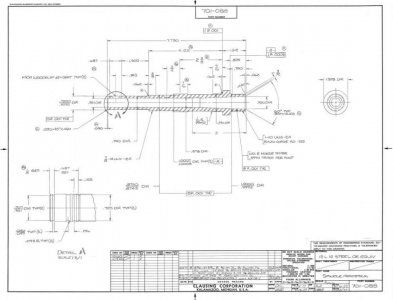

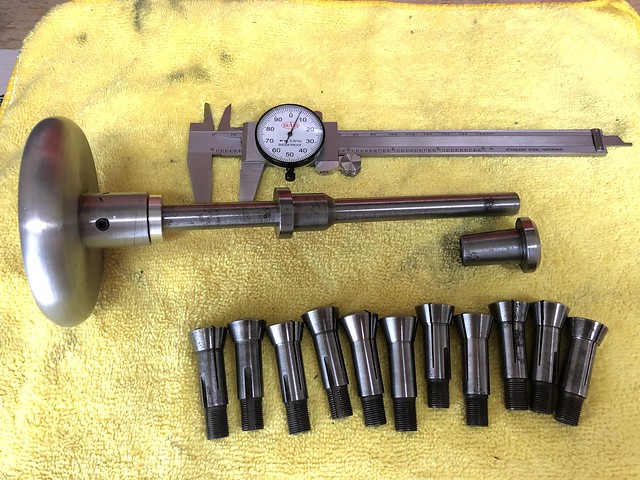

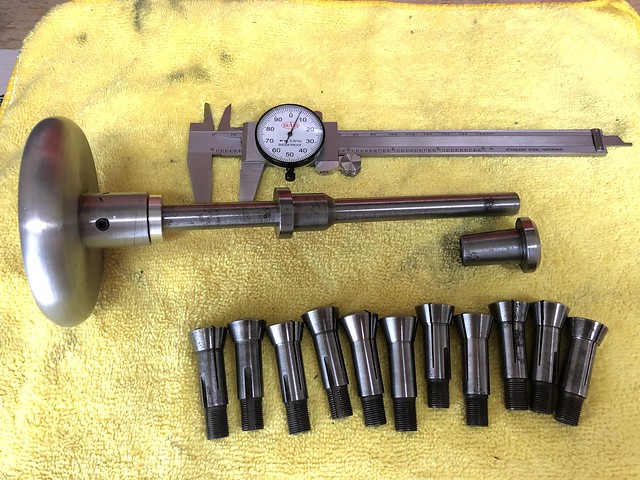

As you can see in the picture the set up came with a spacer that is about 1 inch long , when using that one the tube is not long enough to thread into the collet . I made a 1/4 inch thick spacer to make it fit . My spindle is 8 3/8 long so obviously this fit a shorter spindle . My seller included a picture of the name plate and it was 101.21400 .

Would someone with a 101.07301 Timken or a 101.21400 and a 101.21200 (MK 2) tell me the length of their spindle , please .

I would like to make some pot chucks also called emergency chucks for this set up , the collet thread is not something normal that I could run a die on so I will have to single point it . The thread size is .415 - 27 , has anyone ever heard of that ?

Thanks , Mark .

collets by mark westi, on Flickr

collets by mark westi, on Flickr

As you can see in the picture the set up came with a spacer that is about 1 inch long , when using that one the tube is not long enough to thread into the collet . I made a 1/4 inch thick spacer to make it fit . My spindle is 8 3/8 long so obviously this fit a shorter spindle . My seller included a picture of the name plate and it was 101.21400 .

Would someone with a 101.07301 Timken or a 101.21400 and a 101.21200 (MK 2) tell me the length of their spindle , please .

I would like to make some pot chucks also called emergency chucks for this set up , the collet thread is not something normal that I could run a die on so I will have to single point it . The thread size is .415 - 27 , has anyone ever heard of that ?

Thanks , Mark .

collets by mark westi, on Flickr

collets by mark westi, on Flickr

Last edited: