-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

728VT really unhappy!

- Thread starter 55fairlane

- Start date

- Joined

- May 25, 2023

- Messages

- 117

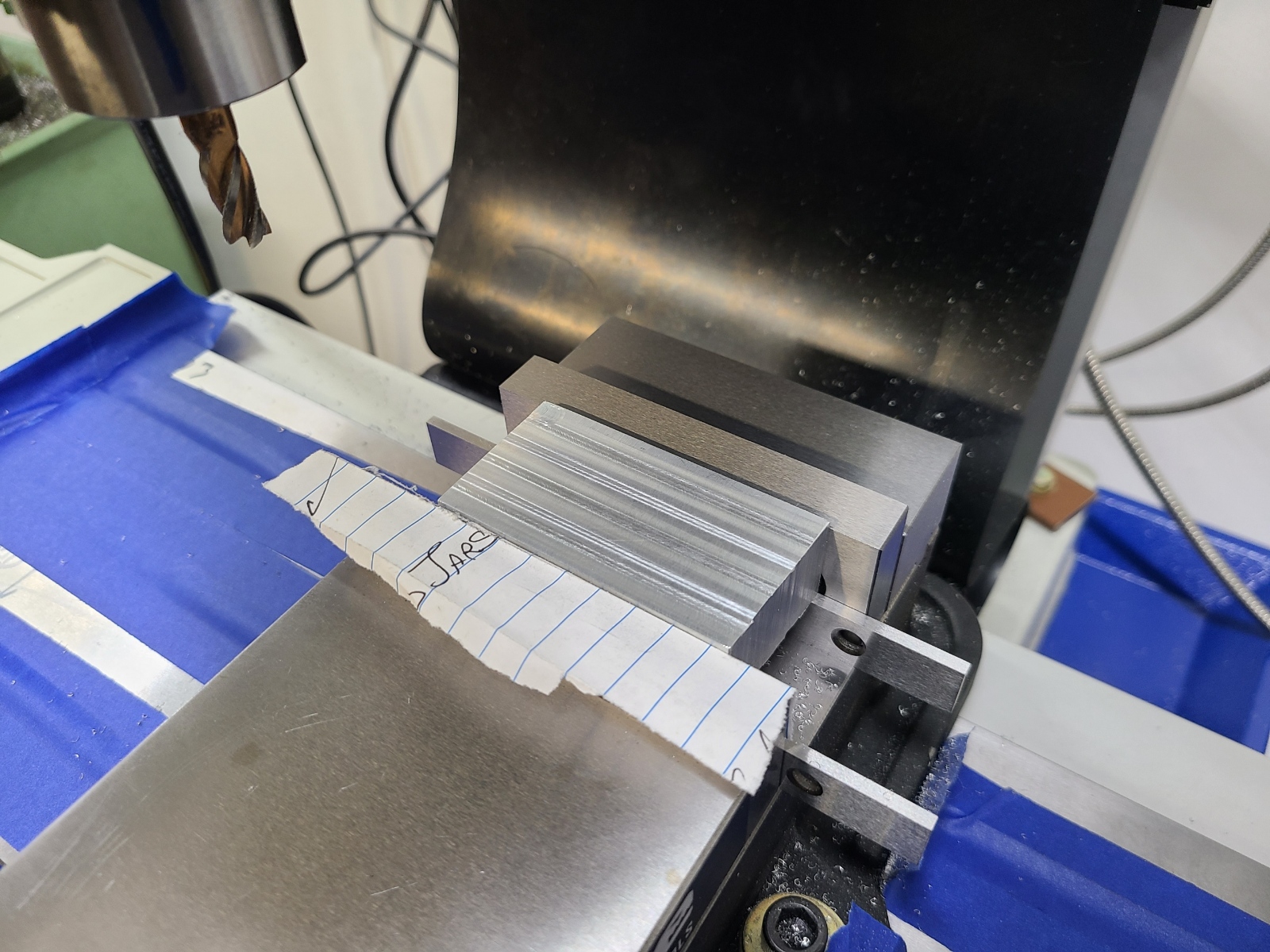

Here are some pictures.

This might be a little hard to see, but as I stepped over in Y, there is no step! That is one of the things that says I got the machine level ( plus no out of tram condition)

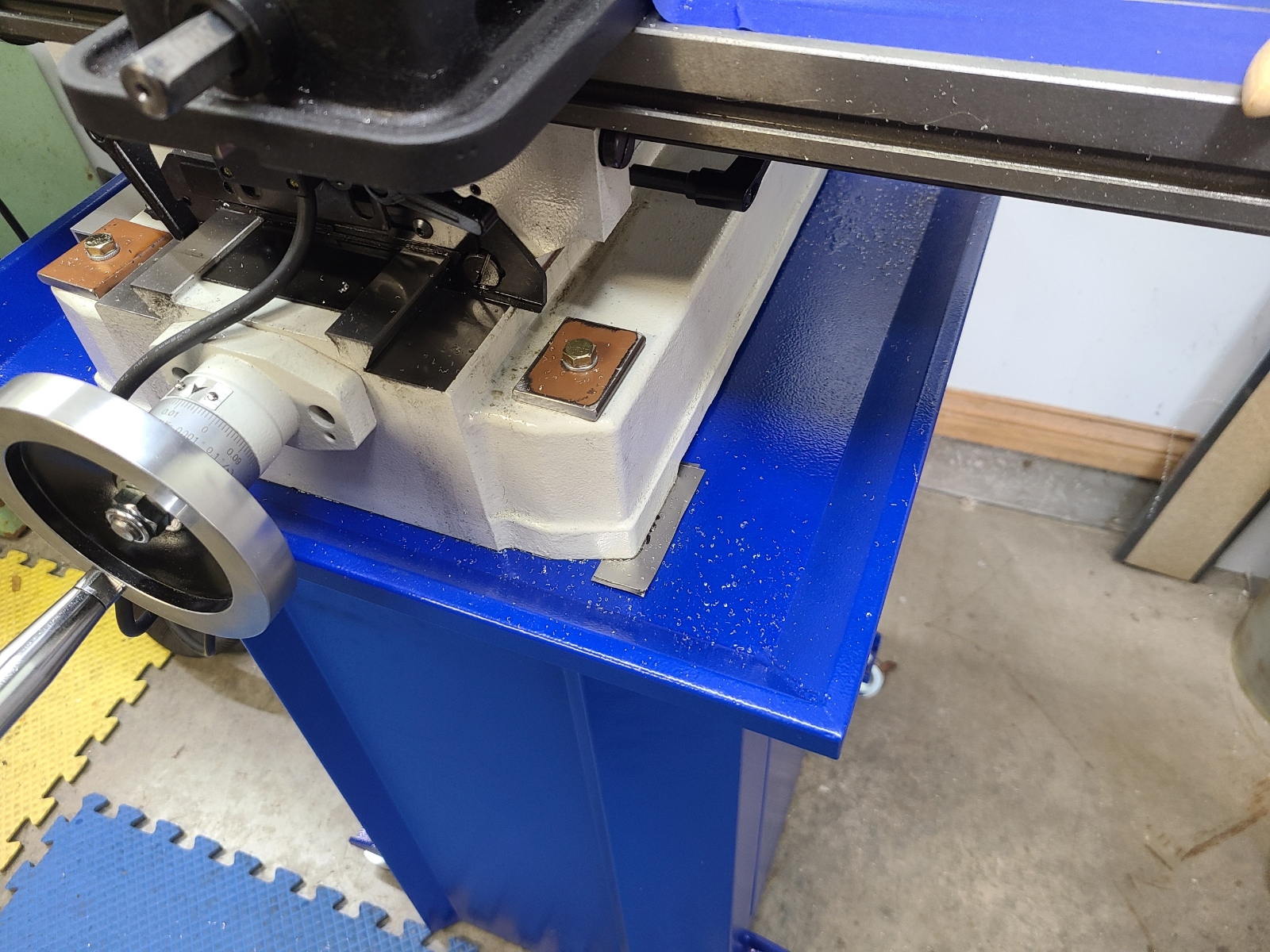

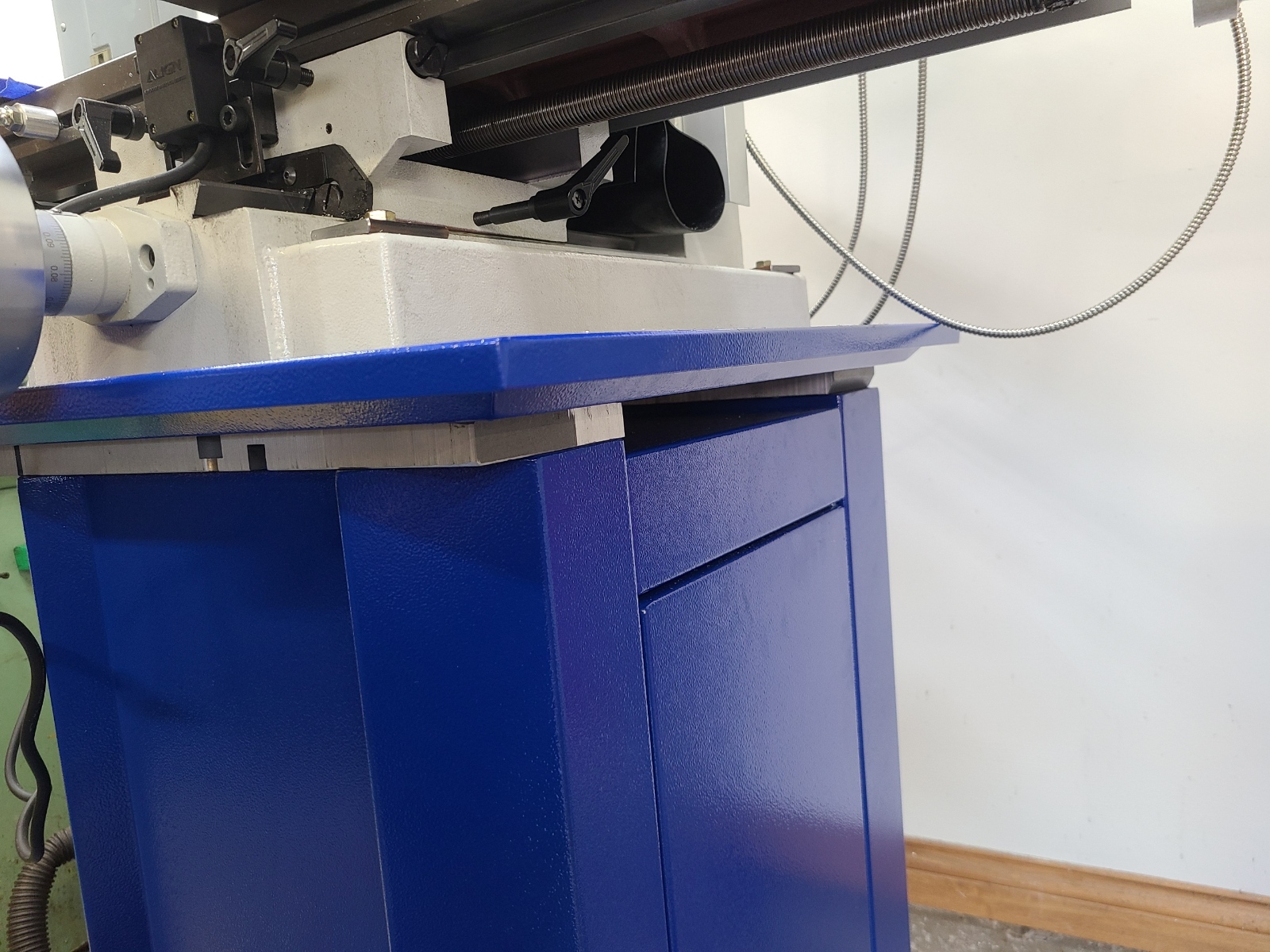

Next 2 pictures show the shims under the front right corner, the large over sized "washers" & the ¾ aluminum plate the the machine base is fully supported on.

This machine is now level (think true, flat & square) and machine to stand is RIGID!

This might be a little hard to see, but as I stepped over in Y, there is no step! That is one of the things that says I got the machine level ( plus no out of tram condition)

Next 2 pictures show the shims under the front right corner, the large over sized "washers" & the ¾ aluminum plate the the machine base is fully supported on.

This machine is now level (think true, flat & square) and machine to stand is RIGID!

- Joined

- Jan 26, 2021

- Messages

- 344

Although it's not mandatory to level a milling machine, I certainly leveled mine. But in your case that shim would really bother me. It kind of defeats the purpose of the aluminum plate the the machine base is sitting on.

- Joined

- May 25, 2023

- Messages

- 117

Ummmm I will disagree with you greatly on both points.Although it's not mandatory to level a milling machine, I certainly leveled mine. But in your case that shim would really bother me. It kind of defeats the purpose of the aluminum plate the the machine base is sitting on.

A) if the mill isn't level, you will not get true flat square cuts....I demand true flat & square

B) the shims do not bother me as much as have a machine that is warped up like a banana. The aluminum are a rock solid foundation to shim against

- Joined

- Jan 26, 2021

- Messages

- 344

So is the base casting on the mill twisted, and you had to shim it to straighten it out?Ummmm I will disagree with you greatly on both points.

A) if the mill isn't level, you will not get true flat square cuts....I demand true flat & square

B) the shims do not bother me as much as have a machine that is warped up like a banana. The aluminum are a rock solid foundation to shim against

And a mill absolutely does not need to be level to get true flat square cuts. It does help with setups though if you're using a level as reference.

Last edited:

- Joined

- May 25, 2023

- Messages

- 117

That is correct.So is the base casting on the mill twisted, and you had to shim it to straighten it out?

A twist in the base of any machine is very common. This not an anomaly or a defect with the PM728VT ....... buy a HAAS or a Mazak or any big name VMC even used and you will need to level & take out the twist of the casting

- Joined

- Jun 12, 2014

- Messages

- 4,810

Level and twist are two separate factors, a mill or lathe for that matter does not need to be level, but the level should be the same incline so no twist. I had similar rigidity issues with the older version of the 1340GT cabinets, the solution one a 1 piece 1/2" steel base on top of each base as well as well as additional bracing and widening the stance. In either case, glad you have a mill that is dialed in and accurate. A bit of a tough road, but at least resolved at the end.

It's worth noting that cast iron moves! Ideally it is stress relieved before finish grinding the reference surfaces. Takes time & $ so think about that in relatioship to where the machine came from. There are always stresses in castings, uneven cooling! Over time those stresses relax and may cause the casting to change shape, slightly/or more.

- Joined

- May 16, 2016

- Messages

- 1,695

So is the base casting on the mill twisted, and you had to shim it to straighten it out?

And a mill absolutely does not need to be level to get true flat square cuts. It does help with setups though if you're using a level as reference.

It's good that you have your machine setup to your satisfaction. However please uinderstand that having a machine level is an old argument and is based on a false premise. The machine must be true to itself. As a trained fitter and turner / toolmaker, and now retired marine engineer, I have used many machines, lathes, mills, shapers etc on board many a ship at sea. Now please explain to me how a machine on a ship at sea can be level. There will be individual moments in time when it's level, but a second later it will not be level. What is important is that when the machine is bolted down that all stresses and bowing and twisting are removed from it, then the usual test cuts are made, final adjustments are done, and the machine is good for service. I have used many machines in this way, and found no difficulty in obtaining the same precision that I would expect while on dry land.Here are some pictures.

This might be a little hard to see, but as I stepped over in Y, there is no step! That is one of the things that says I got the machine level ( plus no out of tram condition) View attachment 480237

Next 2 pictures show the shims under the front right corner, the large over sized "washers" & the ¾ aluminum plate the the machine base is fully supported on.

View attachment 480238View attachment 480239

This machine is now level (think true, flat & square) and machine to stand is RIGID!