- Joined

- May 25, 2023

- Messages

- 117

Ok all here is the update.....my machine has been returned to PM and I will be getting a different brand new mill!

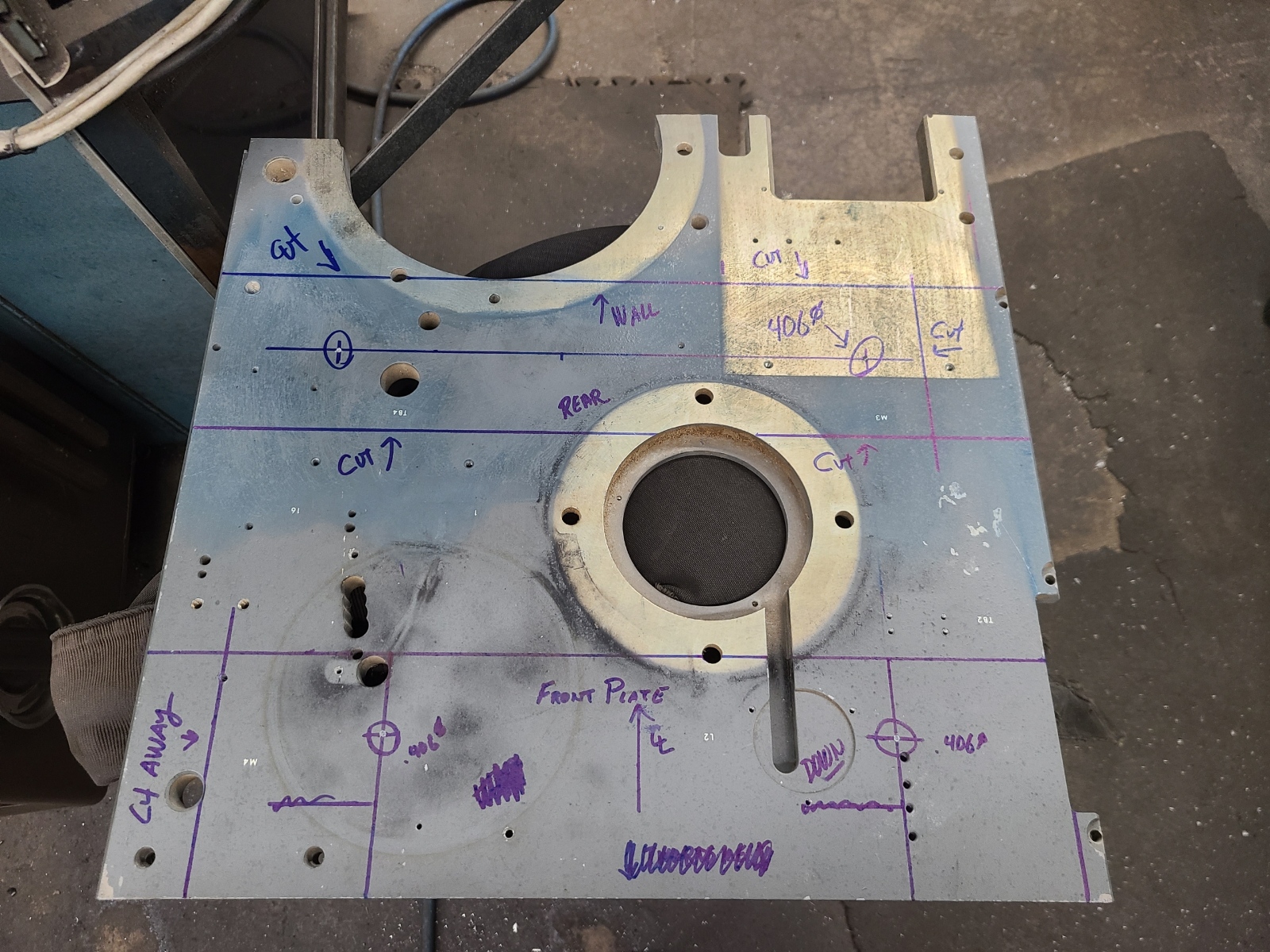

This may be a blessing .....I noticed a couple of anomalies.....as I would tighten up the bolts (that hold the machine to the base) the bolts felt mushy and the next day the bolts wouldn't be tight....plus when I was trying to shim the machine base , shimming did little.....well as you can see in the pictures there are convex shapes in the cabinet & you can see concave L shapes in the chip pan.

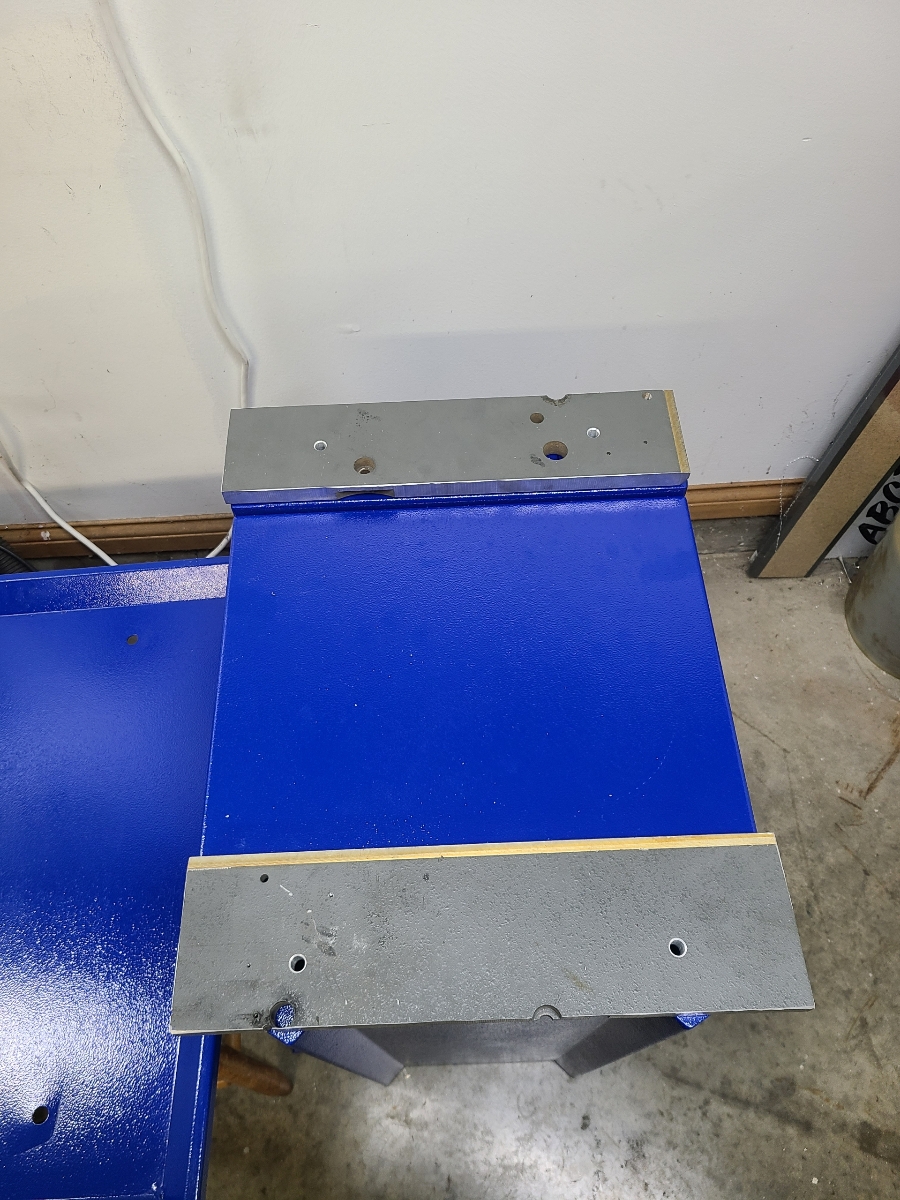

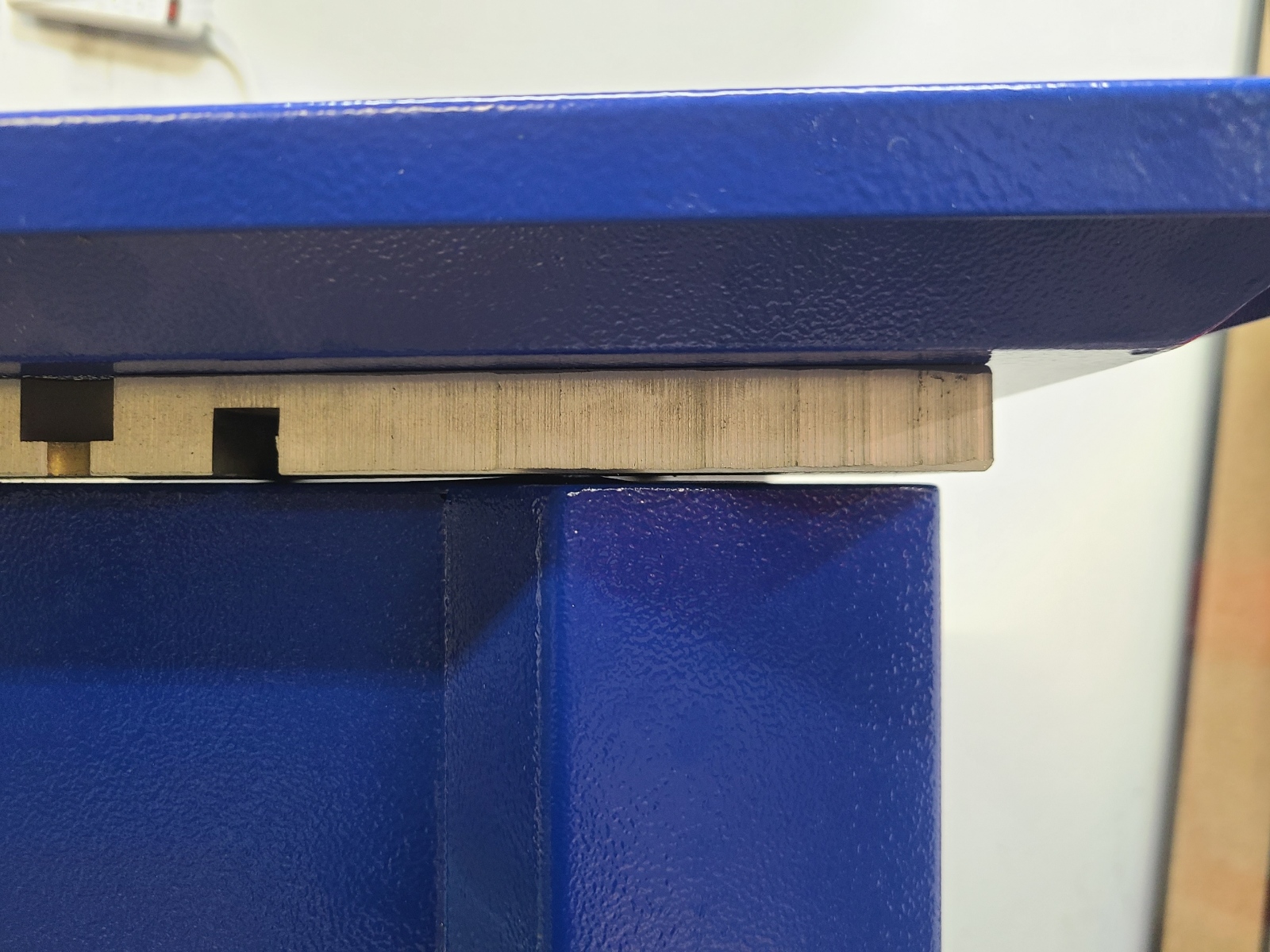

That sheet metal cabinet has no bridge strength....my cure is so e ¾ thick aluminum Plat I salvaged from something.....these will live between the cabinet & the chip pan.....

This may be a blessing .....I noticed a couple of anomalies.....as I would tighten up the bolts (that hold the machine to the base) the bolts felt mushy and the next day the bolts wouldn't be tight....plus when I was trying to shim the machine base , shimming did little.....well as you can see in the pictures there are convex shapes in the cabinet & you can see concave L shapes in the chip pan.

That sheet metal cabinet has no bridge strength....my cure is so e ¾ thick aluminum Plat I salvaged from something.....these will live between the cabinet & the chip pan.....