B

Bill Gruby

Forum Guest

Register Today

Nice work Steve. Looks like you are not going to run into any trouble at all'

"Billy G"

"Billy G"

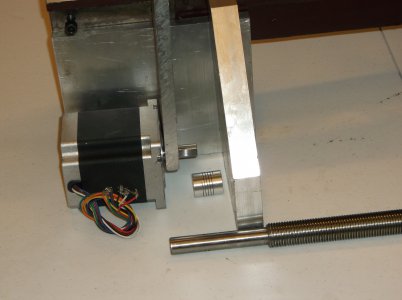

i got the x axis mechanical parts done and assembled they work good, the motor in the vid is from the mill i just hooked it up for testing. i havent done any wiring for the lathe yet. if you watch the very end you can see i didnt get the set screw tight and the coupling is pulling off the motor lol[video=youtube;zwBa5CGJ1O4]http://www.youtube.com/watch?v=zwBa5CGJ1O4[/video]

steve