- Joined

- May 20, 2014

- Messages

- 191

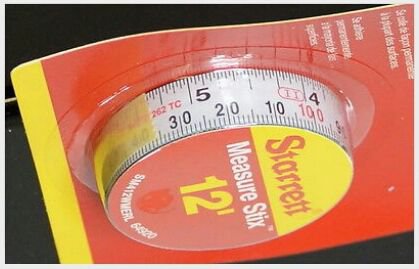

...eBay item 111483477188 is a Starret metal flat tape in imperial & metric which are usually fairly accurate at 60 o F ...

Yeah, I like that. Found them under "Starrett Stix", around $10.

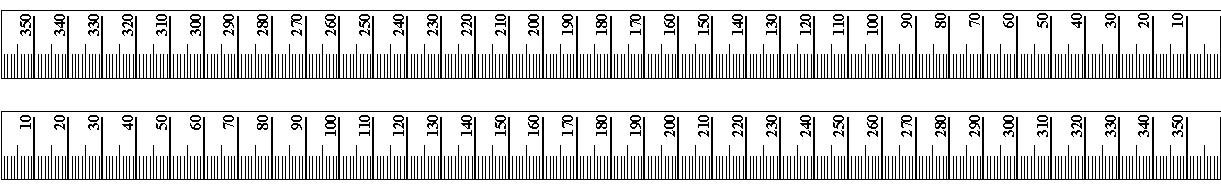

That last one is marked in millimeters, so no need to add the extra 'zero'. Just need to cut off the first 360 millimeters and slice it down the middle. Might need to subtract a little from the disc's diameter to account for the tape's thickness...

Last edited: