- Joined

- Apr 28, 2022

- Messages

- 8

Hi All,

I was very happy to read many of the posts here. We all love machines and many of you are wicked knowledgeable.

So, I’m wiring up my recently acquired 110v SB 9 precision lathe. The motor connections were a bird nest and before I got a chance to identify the mates, many connections fell apart. So, I don’t know what wires go where anymore.

I cracked open the motor and repaired broken wires inside and extended all with new wires with IDs mapped to a picture of the original wires. The one black wire not in the image is coming off the spindle/shaft sprung contact plate which is screwed into the end cap/bearing of the motor

No label or diagram on motor.

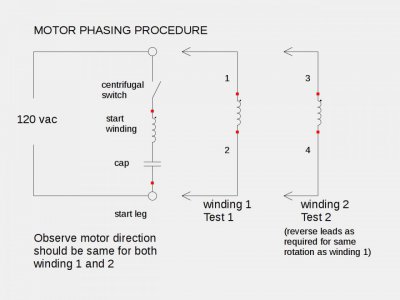

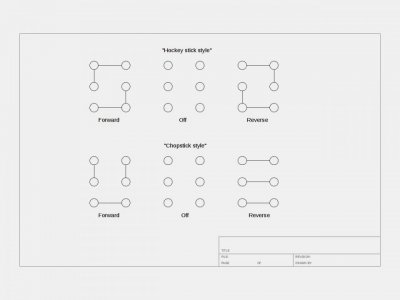

I can likely identy all the wires for the reversing switch just using a meter on the plug and bitter ends.

If anyone sees these picture and knows what the colors mean and where to connect them to the switch I’d be grateful.

I was very happy to read many of the posts here. We all love machines and many of you are wicked knowledgeable.

So, I’m wiring up my recently acquired 110v SB 9 precision lathe. The motor connections were a bird nest and before I got a chance to identify the mates, many connections fell apart. So, I don’t know what wires go where anymore.

I cracked open the motor and repaired broken wires inside and extended all with new wires with IDs mapped to a picture of the original wires. The one black wire not in the image is coming off the spindle/shaft sprung contact plate which is screwed into the end cap/bearing of the motor

No label or diagram on motor.

I can likely identy all the wires for the reversing switch just using a meter on the plug and bitter ends.

If anyone sees these picture and knows what the colors mean and where to connect them to the switch I’d be grateful.