I just added a low profile ER-40 collet chuck to my PM-1022V. I got the back plate from Precision Mathews, the collet chuck from Shars (PM didn't carry one, but their helpful folks pointed me in the right direction) and got the box of collets from LMS. I "needed" the collet chuck for the Turnado freehand metal turning system on order. The collet chuck setup is much lighter than the 3 & 4 jaw chucks - the lathe actually runs a little quieter with the reduced chuck weight. (The gears got a bit noisier after my recent change gear swaps for thread cutting.)

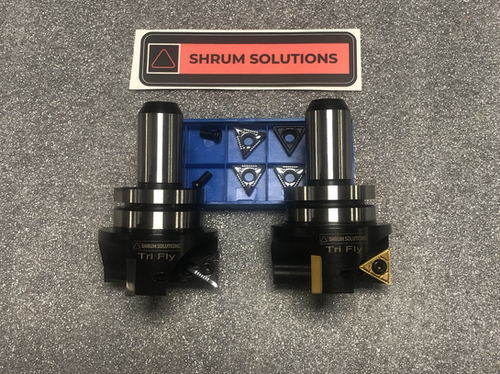

Also, does anyone have a current recommendation for a reasonably priced facing cutter for the PM-728VT mill? I recently obtained an impressive die filer kit from Andy Lofquist that requires some precision flattening. Looks like a challenging kit that should teach me a lot. I removed a 1 1/2 hp motor with variable speed control from a free treadmill advertised online. The motor setup that Clickspring used for his die filer is quite expensive, so I went for the cheapest option I could find....so I could buy more tools.

This retirement thing is great....

Also, does anyone have a current recommendation for a reasonably priced facing cutter for the PM-728VT mill? I recently obtained an impressive die filer kit from Andy Lofquist that requires some precision flattening. Looks like a challenging kit that should teach me a lot. I removed a 1 1/2 hp motor with variable speed control from a free treadmill advertised online. The motor setup that Clickspring used for his die filer is quite expensive, so I went for the cheapest option I could find....so I could buy more tools.

This retirement thing is great....