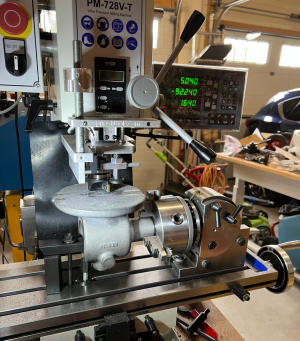

Honestly, I'm not sure how much time I have into it. It was a fairly long build, mostly because I don't get a ton of time to mess around in the shop. I would guess around 40 hours of shop time, mostly because I spent way too long trying to find ways to hold things and plan ahead for the next operation. I attached a DXF of a little gasket I drew and laser cut for mine. It might come in handy even just as a template for the drilling for the cover. Though you might want to expand it a little. Mine had an extra page suggesting it might be needed. I thought mine would be ok, but I ended up breaking through on one screw hole. There are enough that it's not a big issue, but it's something to be aware of. I think I was about 0.050 off. lol. Owell.

Overall, it is a lot of fun to build and a useful machine for a home shop. I've used it on a few projects now and it's worked great.

I found a pic of it mounted to a board along with the motor and controller from the treadmill. I kept the flywheel from the treadmill and cut the blank pulley from MLA to match. I did that as the multi-V belts they use are able to handle a smaller drive pulley, so the reduction is higher. The motor is speced for 10,000 RPM, so I wanted to slow the filer down. Keeping the flywheel also keeps the fan that is designed into it. These motors tend to like to be cooled. I think the original belt was broken, I got this one from Amazon.

View attachment 406062