- Joined

- Dec 3, 2017

- Messages

- 1,920

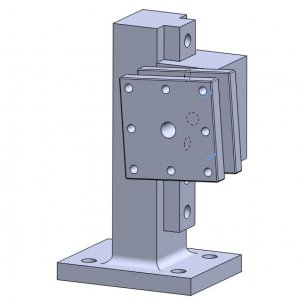

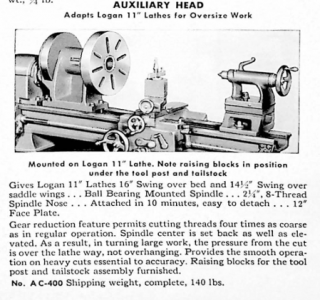

There’s a model engineer from the UK I believe that has a rig he built for getting more capacity. I didn’t save the link because I don’t want to deal with overly large pieces of metal to begin with. But just saying, if you head down this rabbit hole, there’s more to find. Lol