- Joined

- Feb 1, 2015

- Messages

- 9,646

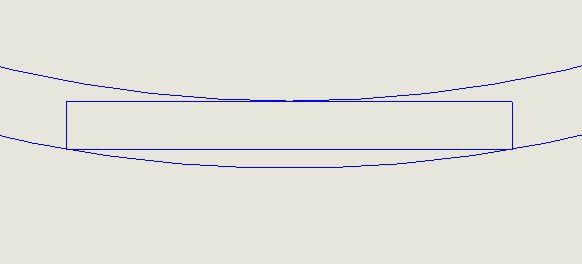

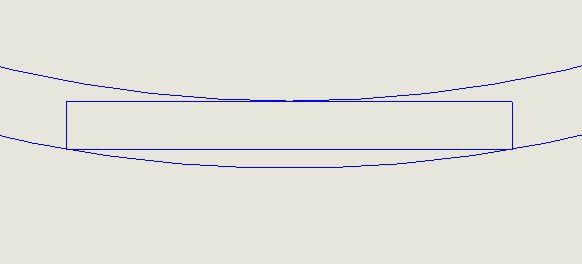

The parallels are not measuring an average width but they are not measuring the narrowest width either. Consider a circular slot. The outer parallel would touch at its ends while the inner parallel would touch at the middle. The distance between the parallels would not be a measure of the width of the slot. In fact, they are not even measuring the maximum width for a key unless the key is shorter than the parallels or the parallels are longer than the slot.

On another note, I watched the video on You Tube. No one had made a comment about measuring the slot width with adjustable parallels in the first 100 or so comments. This is the danger of You Tube How To's. Many people are using them as their textbook and don't know enough to batch an error on the part of the presenter.

On another note, I watched the video on You Tube. No one had made a comment about measuring the slot width with adjustable parallels in the first 100 or so comments. This is the danger of You Tube How To's. Many people are using them as their textbook and don't know enough to batch an error on the part of the presenter.