Nice web site Bill,

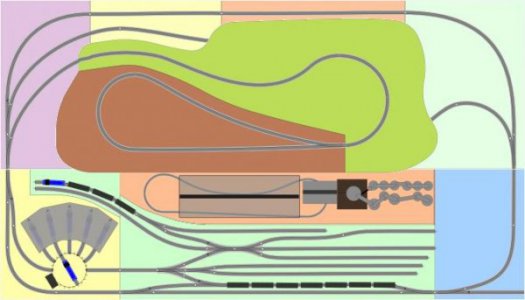

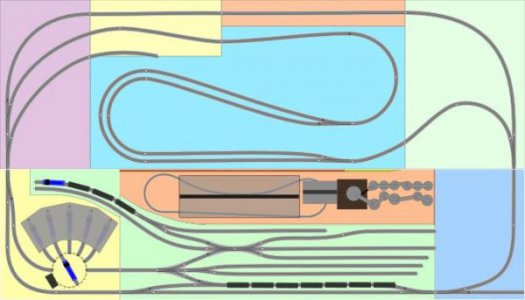

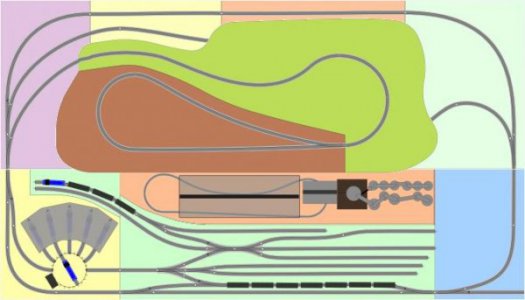

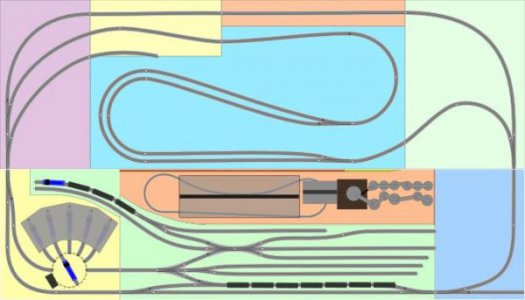

I had started an HO scale layout about 40 years ago. But then I had to move and never finished it. The layout was a model of the Union railroad in Pittsburgh PA. It was a fairly small layout but it was complete with a steel mill, a round house, and a coal mine. Here's some photos of the plans for the layout:

In the following picture the brown and green area in the middle is a mountain. There is an entire coal mine diorama in the loop in the brown area. The coal mine is not shown in this drawing.

Below in the pink area is the steel mill with an animated rolling mill. The tiny track is N-scale track used to simulate a small industrial train about the side of a typical fork lift to move stuff around inside the steel mill.

Below that is the "yard" and to the left the roundhouse. This layout is as cramped as HO scale will allow for. In fact, it's actually cramped to the hilt. I used all flex track and make curves as small as my engines and rolling stock would permit. Far tighter radius than used on a typical HO layout.

The coal mine mountain lifts off to expose a tunnel underneath. The tunnel allow for hiding one train. So you can have one train go into the tunnel and a different train come out. Nice little optical illusion trick.

I have all the parts necessary to build this layout in the attic. It was half built at one time but I had to disassemble it to move and never got around to putting it back together again. I should probably sell all this junk because I'm never going to put this back together again.

In fact, at this point if I were going to mess around with model railroading I would rather focus on the outdoor garden train. I have big ambitions there too.

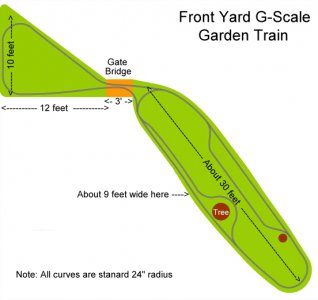

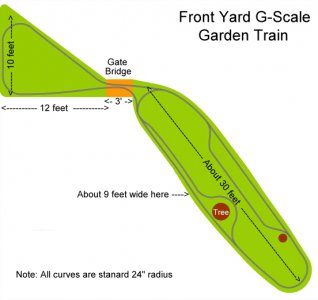

Here's my initial Garden Train plan (not too ambitious)

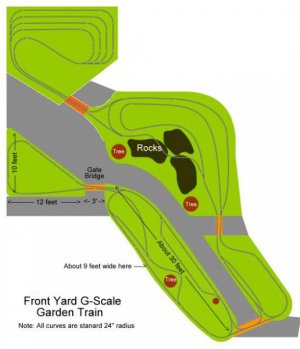

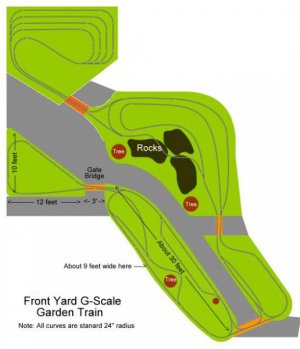

Then I got carried away,

This is designed based on the terrain in front of my cottage. The gray is pathways. The orange represent draw bridges.

It's a crazy layout. I would love to do it, but I can't find much time to work on it.

I have too many pokers in the fire, I think the fire went out a long time ago.