- Joined

- Sep 15, 2017

- Messages

- 321

Has anyone here ever tried to fit a 7 inch angle grinder disc on a bench grinder .I am planning on trying it so as the issue of grinding on the side of a proper bench grinder wheel is not an issue as a angle grinder disc is designed to do this .

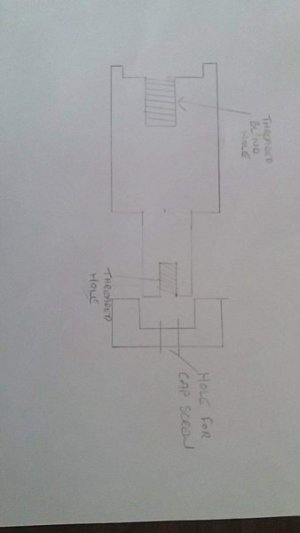

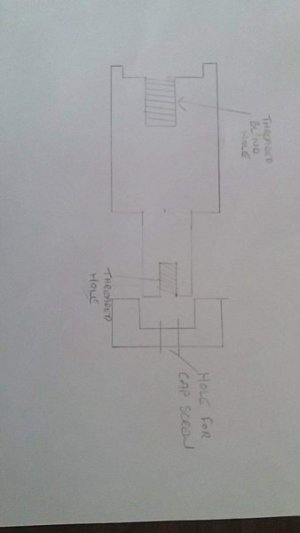

As you can see from the pics below I plan to make a spigot with an internal thread and then a shaft this would the threaded spigot would retain the belt sander wheel in place of the nut and then the shaft would be turned down to 22 mm for the disc to go onto ,there would be 2 sandwich washers just like an angle grinder uses to retain the grinder disc .Also the disc would have support from the belt sander wheel as this is same diameter .I think it would make life easier being able to just change a disc rather than reglueing sand paper onto the old disc every time it needs to be replaced like it is now

The grinding disc would be well within its rpm limits 5000 rpm but still usable at 2600 rpm as this is my bench grinder rpm .It would not be for large jobs but just gives and option of grinding on the side of a wheel .i would also use it for sharpening drill bits with my jig . The spigot shaft would look something similar to the rough sketch I attached and from the pictures I think you can see what I plan to do .

Is it a feasible idea ?

Any warnings or advice appreciated

As you can see from the pics below I plan to make a spigot with an internal thread and then a shaft this would the threaded spigot would retain the belt sander wheel in place of the nut and then the shaft would be turned down to 22 mm for the disc to go onto ,there would be 2 sandwich washers just like an angle grinder uses to retain the grinder disc .Also the disc would have support from the belt sander wheel as this is same diameter .I think it would make life easier being able to just change a disc rather than reglueing sand paper onto the old disc every time it needs to be replaced like it is now

The grinding disc would be well within its rpm limits 5000 rpm but still usable at 2600 rpm as this is my bench grinder rpm .It would not be for large jobs but just gives and option of grinding on the side of a wheel .i would also use it for sharpening drill bits with my jig . The spigot shaft would look something similar to the rough sketch I attached and from the pictures I think you can see what I plan to do .

Is it a feasible idea ?

Any warnings or advice appreciated