That chip guard looks real nice. I'm planning to build out my "light bar" a little bit (toward the spindle an inch or so) to have room to extend a guard inward and clear the motor. Really good idea to use a rubber cushion.

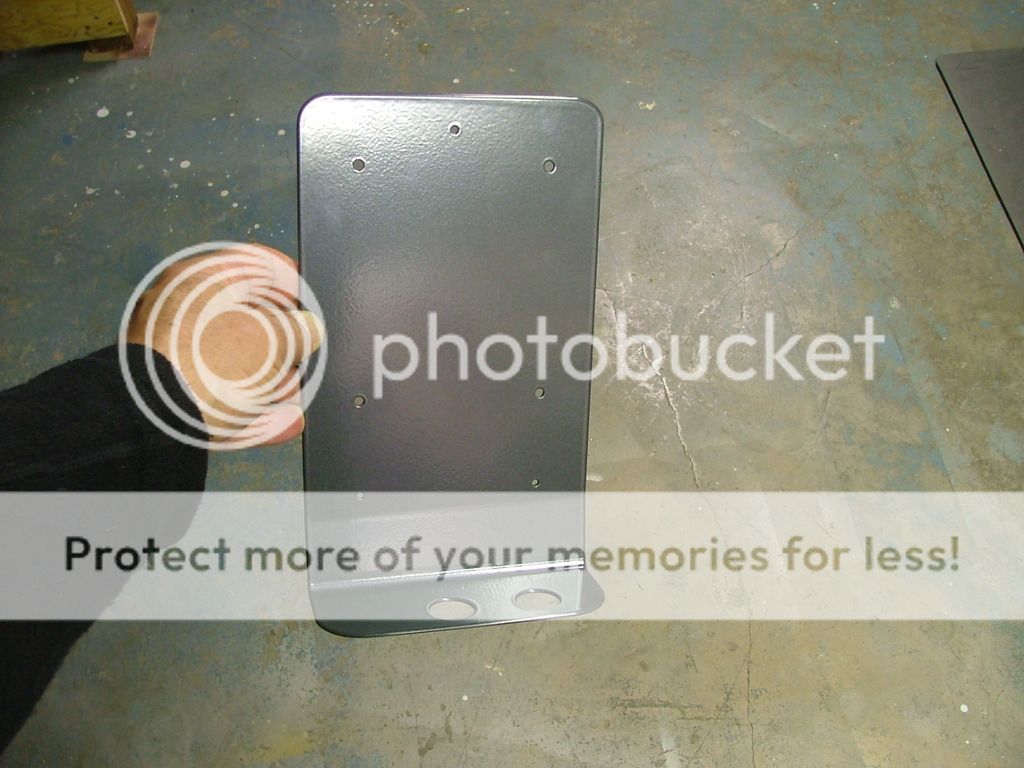

Nice clean finish on the VFD mount also.

Nice clean finish on the VFD mount also.