- Joined

- Oct 18, 2016

- Messages

- 2,872

MORE PROGRESS:

I've sorted the problem I had with the front gib so the carriage is installed and the gibs adjusted up. When I slide the carriage along the ways, the effort required doesn't change much as it gets

close to the headstock: more evidence that my ways aren't too badly worn. I'm also enjoying the completely slop-free cross feed now that the new shaft and nut are installed.

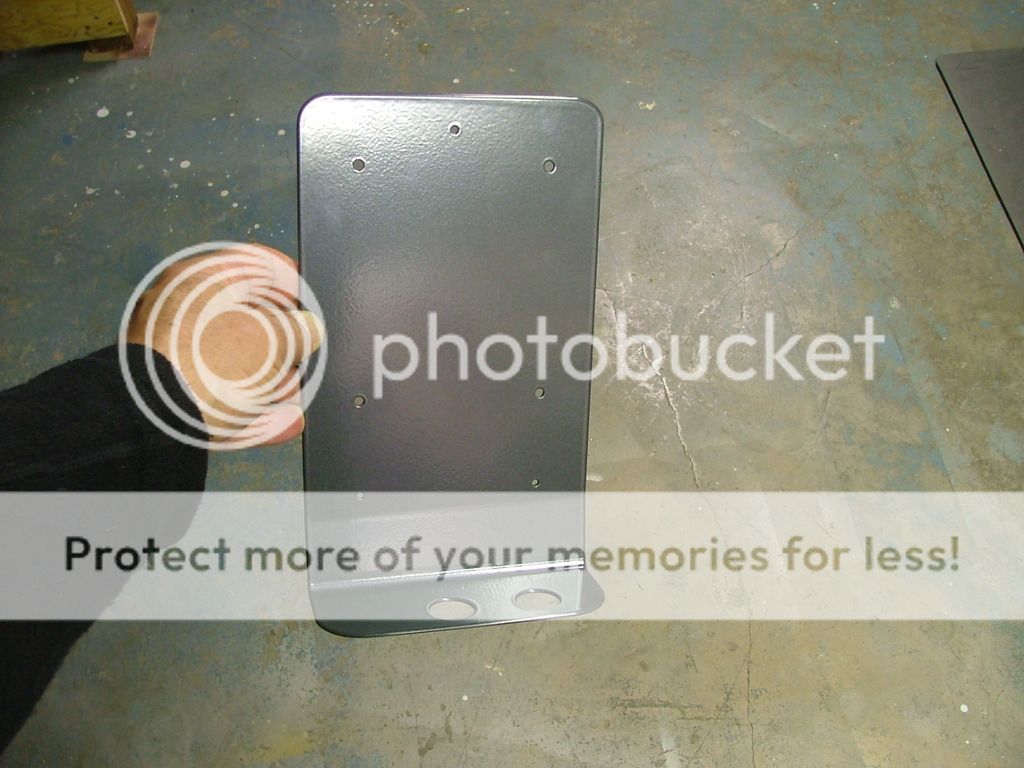

Also installed the belt guard. When the eBay sourced bench stand arrived, it didn't have one of the holes required for mounting the belt guard so it was mounted in place, marked and removed for

drilling. With a jobber length drill, there wasn't enough room in my bench style DP with the table all the way down. A screw machine length drill did the job (just). Might need to give some thought

to a bigger drill press at some point!

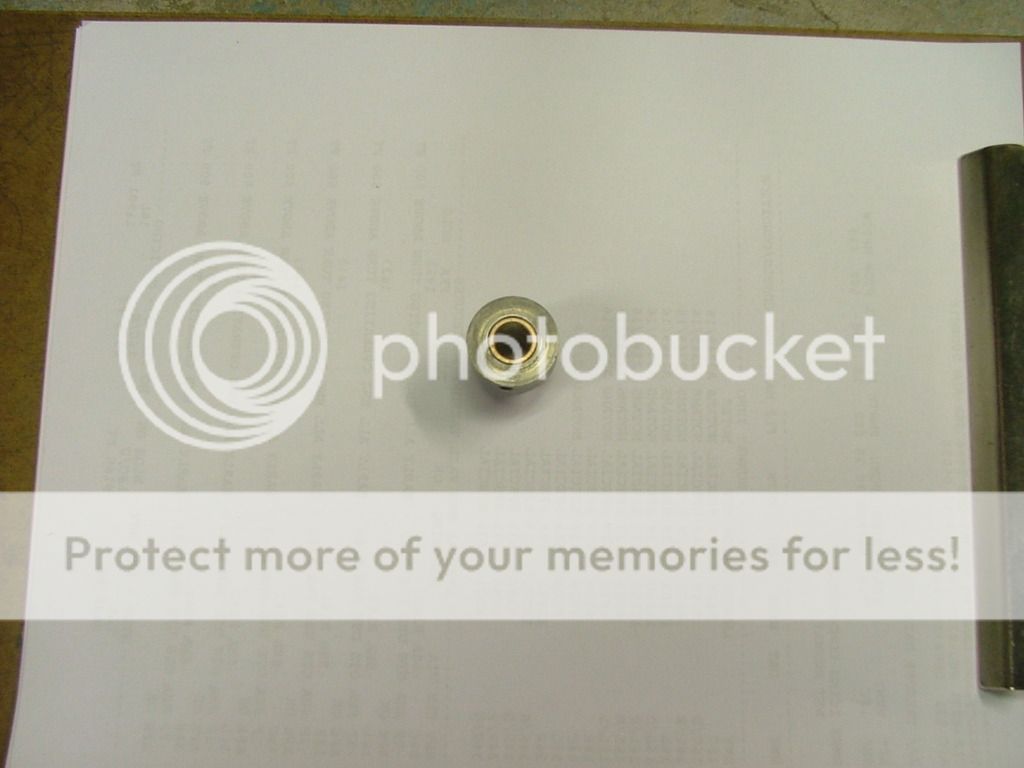

Went ahead and pressed a new bronze bushing in for the compound: the old one was badly worn. The steel bush that it presses into is an inch long, but the original bushing was only .5"

in length. To give it more support, I bought a part .750 long. Popped the bushing into the freezer, and, when my wife wasn't looking, heated the steel part up in the toaster oven before pressing them together. The bushing is McMaster Carr part number 6391K176.

All that was left on the carriage was to was to re-assemble the compound and add the QCTP.

I've sorted the problem I had with the front gib so the carriage is installed and the gibs adjusted up. When I slide the carriage along the ways, the effort required doesn't change much as it gets

close to the headstock: more evidence that my ways aren't too badly worn. I'm also enjoying the completely slop-free cross feed now that the new shaft and nut are installed.

Also installed the belt guard. When the eBay sourced bench stand arrived, it didn't have one of the holes required for mounting the belt guard so it was mounted in place, marked and removed for

drilling. With a jobber length drill, there wasn't enough room in my bench style DP with the table all the way down. A screw machine length drill did the job (just). Might need to give some thought

to a bigger drill press at some point!

Went ahead and pressed a new bronze bushing in for the compound: the old one was badly worn. The steel bush that it presses into is an inch long, but the original bushing was only .5"

in length. To give it more support, I bought a part .750 long. Popped the bushing into the freezer, and, when my wife wasn't looking, heated the steel part up in the toaster oven before pressing them together. The bushing is McMaster Carr part number 6391K176.

All that was left on the carriage was to was to re-assemble the compound and add the QCTP.

Last edited: