- Joined

- Sep 20, 2012

- Messages

- 560

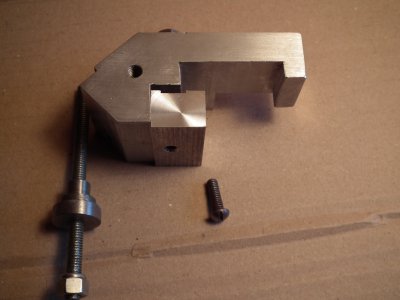

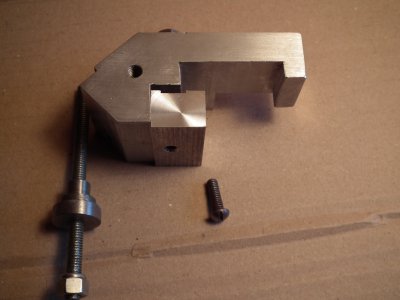

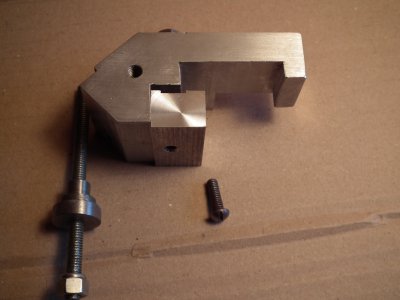

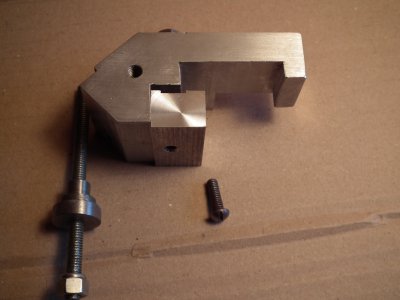

Just my take on a carriage stop for flat ways, I found with my previous attempt at making one, that a slight knock was all it took to dislodge it slightly.

I think this was due to the stick out needed to mount the DTI and stop in the same piece, unlike the Atlas design which is very close to the front of the ways, and has double bolts for extra grip.

Having nothing positive to clamp on as per a V way bed, I made mine to reach across and positively locate across the ways. The only downside is that it it doesn't pass by the side of the headstock, this hasn't been a problem for me so far.

The clamping piece is held snug against the body by the screw shank, it's depth enables it to be opened wide enough to allow fiddle free placing onto the ways.

The eagle eyed picture clickers amongst you will have noticed the glued on shim, this of course is a sacrificial way wear strip.....that's my story and anyway I'm sticking to it...

I milled this on my lathe using TCT wood router bits, held in the three jaw, just working with what I've got..

The positive stop screw and nut are work in progress as knurling is not yet one of my skills..

Thanks to all who have posted your designs on here previous, you will probably spot ideas from various others in mine..

Bernard

I think this was due to the stick out needed to mount the DTI and stop in the same piece, unlike the Atlas design which is very close to the front of the ways, and has double bolts for extra grip.

Having nothing positive to clamp on as per a V way bed, I made mine to reach across and positively locate across the ways. The only downside is that it it doesn't pass by the side of the headstock, this hasn't been a problem for me so far.

The clamping piece is held snug against the body by the screw shank, it's depth enables it to be opened wide enough to allow fiddle free placing onto the ways.

The eagle eyed picture clickers amongst you will have noticed the glued on shim, this of course is a sacrificial way wear strip.....that's my story and anyway I'm sticking to it...

I milled this on my lathe using TCT wood router bits, held in the three jaw, just working with what I've got..

The positive stop screw and nut are work in progress as knurling is not yet one of my skills..

Thanks to all who have posted your designs on here previous, you will probably spot ideas from various others in mine..

Bernard

Last edited: