- Joined

- Jun 12, 2018

- Messages

- 21

Hi All,

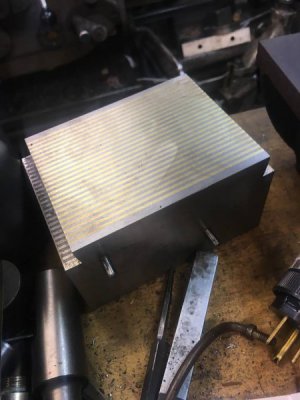

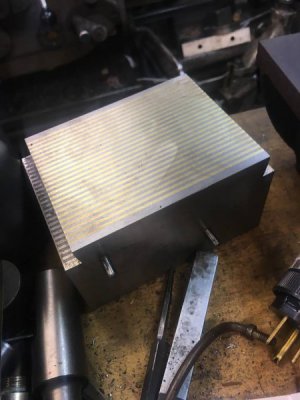

At the same sale that I purchased my Sanford grinder from 2 months ago; I scored a number of other items. The photos are of an Anton adjustable angle magnetic transfer block. Being a tool and die shop, I think, it's something that would be on a shelf as needed tooling.... I've personally never seen one like this. I don't see any way to adjust the angle. I did find a website for Anton Tools, but I've gotten no answer from them via email and the phone went to voice mail after a number of rings. The website showed an adjustable vee block but nothing like this. The part that rotates is frozen and I really don't want to beat on it to get it to move. Any ideas? Thanks!

At the same sale that I purchased my Sanford grinder from 2 months ago; I scored a number of other items. The photos are of an Anton adjustable angle magnetic transfer block. Being a tool and die shop, I think, it's something that would be on a shelf as needed tooling.... I've personally never seen one like this. I don't see any way to adjust the angle. I did find a website for Anton Tools, but I've gotten no answer from them via email and the phone went to voice mail after a number of rings. The website showed an adjustable vee block but nothing like this. The part that rotates is frozen and I really don't want to beat on it to get it to move. Any ideas? Thanks!