I'm utilizing some 1/4" x 8" mild flat steel that we have left over from an old project for fabricating gussets that I'm welding into the "inside" of some 4.1 mild C-channel that we also have on hand.

To begin with, I used our 10" Evolution sliding saw to cut the strips, and my mistake was cutting the strips too wide....but more on that to come. After employing a friend's horizontal metal bandsaw to cut each 8" long strip into three equal length rectangles (roughly 2-5/8" long), I used a thin template that I cut out of sheet metal to draw the shape of the gusset onto said 1/4" rectangles.

Initially, my thought was that I should leave some excess that I could "easily" grind away, but the truth is that these little rectangles are much tougher to shape than I thought they would be. As I don't wish to deform the grinding stone on our bench grinder, I've tried to utilize both a belt sander and an angle grinder as alternatives. Both of these tools will work, eventually, but I was hoping to get some suggestions from the forum board as to how best go about something like this.

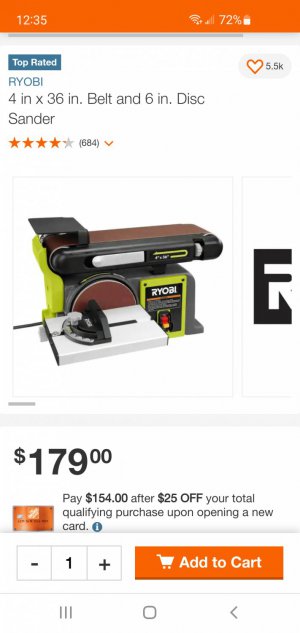

I've seen combination belt/bench sanders -- like the 4" x 36" belt / 8" disc machine depicted below -- that are advertised as being capable of both wood and metal work, but I've got some doubts about a machine like this. Regardless, I'd appreciate some thoughts from anyone who's actually negotiated this metal working hurdle in the past.

Thank you kindly for your time...

To begin with, I used our 10" Evolution sliding saw to cut the strips, and my mistake was cutting the strips too wide....but more on that to come. After employing a friend's horizontal metal bandsaw to cut each 8" long strip into three equal length rectangles (roughly 2-5/8" long), I used a thin template that I cut out of sheet metal to draw the shape of the gusset onto said 1/4" rectangles.

Initially, my thought was that I should leave some excess that I could "easily" grind away, but the truth is that these little rectangles are much tougher to shape than I thought they would be. As I don't wish to deform the grinding stone on our bench grinder, I've tried to utilize both a belt sander and an angle grinder as alternatives. Both of these tools will work, eventually, but I was hoping to get some suggestions from the forum board as to how best go about something like this.

I've seen combination belt/bench sanders -- like the 4" x 36" belt / 8" disc machine depicted below -- that are advertised as being capable of both wood and metal work, but I've got some doubts about a machine like this. Regardless, I'd appreciate some thoughts from anyone who's actually negotiated this metal working hurdle in the past.

Thank you kindly for your time...