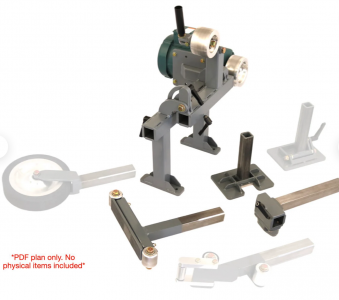

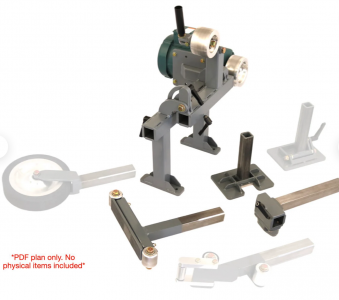

keeena .... Apparently, Jeremy Schmidt, at JersWoodshop, designed the sander to be used in either the vertical or horizontal positions, which makes the finished product very versatile. It's funny how certain things grab one's attention, but I really liked the design of his stand base right away. Any idea why the photo (below) has certain parts of the machine obscured/faded? Does this mean that v2.0 dropped those components?