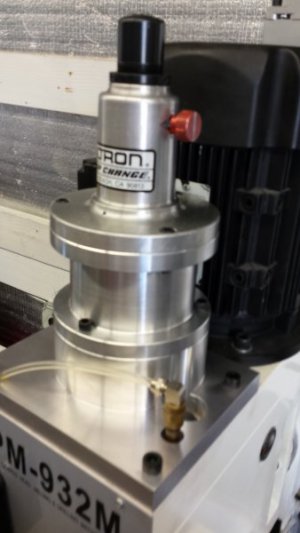

I picked up an Ultron kit recently, (sadly without instructions), and have had no luck contacting someone at the company for a pdf instruction file. Their contact page on the website does not work and their phone goes to FAX after a few unanswered rings.

Anyone out there that can help out?

Thanks,

Eric

Anyone out there that can help out?

Thanks,

Eric