-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone Have Access to a Laser or Water Jet?

- Thread starter Weldo

- Start date

- Joined

- Sep 7, 2019

- Messages

- 674

So here's where I'm at with Send Cut Send. They have a minimum order fee of $29. I needed two separate parts cut, one like the picture above and one is a simple strip at 0.615" x 16". Turns out I could get three of each cut and still just pay the minimum of $29. I had those two items in my shopping cart for a day or two and they sent me a coupon code for 10% off. I ended up getting four of each part for $30.02 total cut from 0.119" mild steel.

Awesome deal in my opinion! This gives up home shop guys an incredible capability. I'll keep you all posted on the process.

Also I want to mention that there's an eBay seller I've bought material from before that can do custom laser cutting. His eBay name is synergysteeldesigns and is based out of Chambersburg, Pennsylvania. He carries all kinds and sizes of plates and sheet stock. He quoted me $20 plus $10 shipping for two of each part mentioned above, so four parts total. Also a very reasonable deal. Just another contact to keep in mind.

Awesome deal in my opinion! This gives up home shop guys an incredible capability. I'll keep you all posted on the process.

Also I want to mention that there's an eBay seller I've bought material from before that can do custom laser cutting. His eBay name is synergysteeldesigns and is based out of Chambersburg, Pennsylvania. He carries all kinds and sizes of plates and sheet stock. He quoted me $20 plus $10 shipping for two of each part mentioned above, so four parts total. Also a very reasonable deal. Just another contact to keep in mind.

- Joined

- Jun 27, 2016

- Messages

- 378

Sendcutsend is right around the corner from me. They are really busy, 24/7, their business has taken off. Constant shipping and receiving. They have also expanded the materials that they offer. Pretty amazing to see their business grow.

- Joined

- Sep 7, 2019

- Messages

- 674

Update from SendCutSend...

So I sent in my two drawings and completed the checkout process on Monday, July 6. I paid with PayPal so that's nice and convenient. I got a confirmation email instantly. An hour and a half later I got another email with a link that allowed me to track my order as it progressed through their shop.

About 24 hours after that my order was "Being reviewed and prepped for the laser". Two more days passed and now my parts are "Undergoing final inspection" Another 2 hours and they have shipped! Estimated delivery is Monday, July 13.

I am super pleased with this whole thing. The process is easy to follow and understand. The turn around time for custom laser cut parts is awesome. If my parts arrive on Monday it will be exactly 7 days from drawings sent to parts in hand. This is a really cool service! Many thanks to @jwmelvin for the heads up!

Learning a little bit of basic CAD was one of the things I did over the quarantine a few months ago and it was so worth it! If anyone is considering learning, do it! I downloaded LibreCAD for free and watched a few YouTube vids to get a basic idea, now I can cobble up simple 2D parts and have them laser cut. This is amazing!

So I sent in my two drawings and completed the checkout process on Monday, July 6. I paid with PayPal so that's nice and convenient. I got a confirmation email instantly. An hour and a half later I got another email with a link that allowed me to track my order as it progressed through their shop.

About 24 hours after that my order was "Being reviewed and prepped for the laser". Two more days passed and now my parts are "Undergoing final inspection" Another 2 hours and they have shipped! Estimated delivery is Monday, July 13.

I am super pleased with this whole thing. The process is easy to follow and understand. The turn around time for custom laser cut parts is awesome. If my parts arrive on Monday it will be exactly 7 days from drawings sent to parts in hand. This is a really cool service! Many thanks to @jwmelvin for the heads up!

Learning a little bit of basic CAD was one of the things I did over the quarantine a few months ago and it was so worth it! If anyone is considering learning, do it! I downloaded LibreCAD for free and watched a few YouTube vids to get a basic idea, now I can cobble up simple 2D parts and have them laser cut. This is amazing!

- Joined

- Jun 27, 2016

- Messages

- 378

Glad to hear that SendCutSend did good. They started out a software developer, that why the website is so polished. The main guy is a gearhead, needed parts made and it kinda took off from what I understand.

- Joined

- Sep 7, 2019

- Messages

- 674

That’s cool! It’s an untapped market as far as I know. Usually laser cutting and the like is reserved for manufacturing and industrial customers. It’s really cool to see it marketed toward hobbyists and homeowners. All over Etsy there’s people who offer laser services but they can only do thin plywood, balsa, acrylic and such craft type materials.

- Joined

- Sep 7, 2019

- Messages

- 674

Parts Acquired!

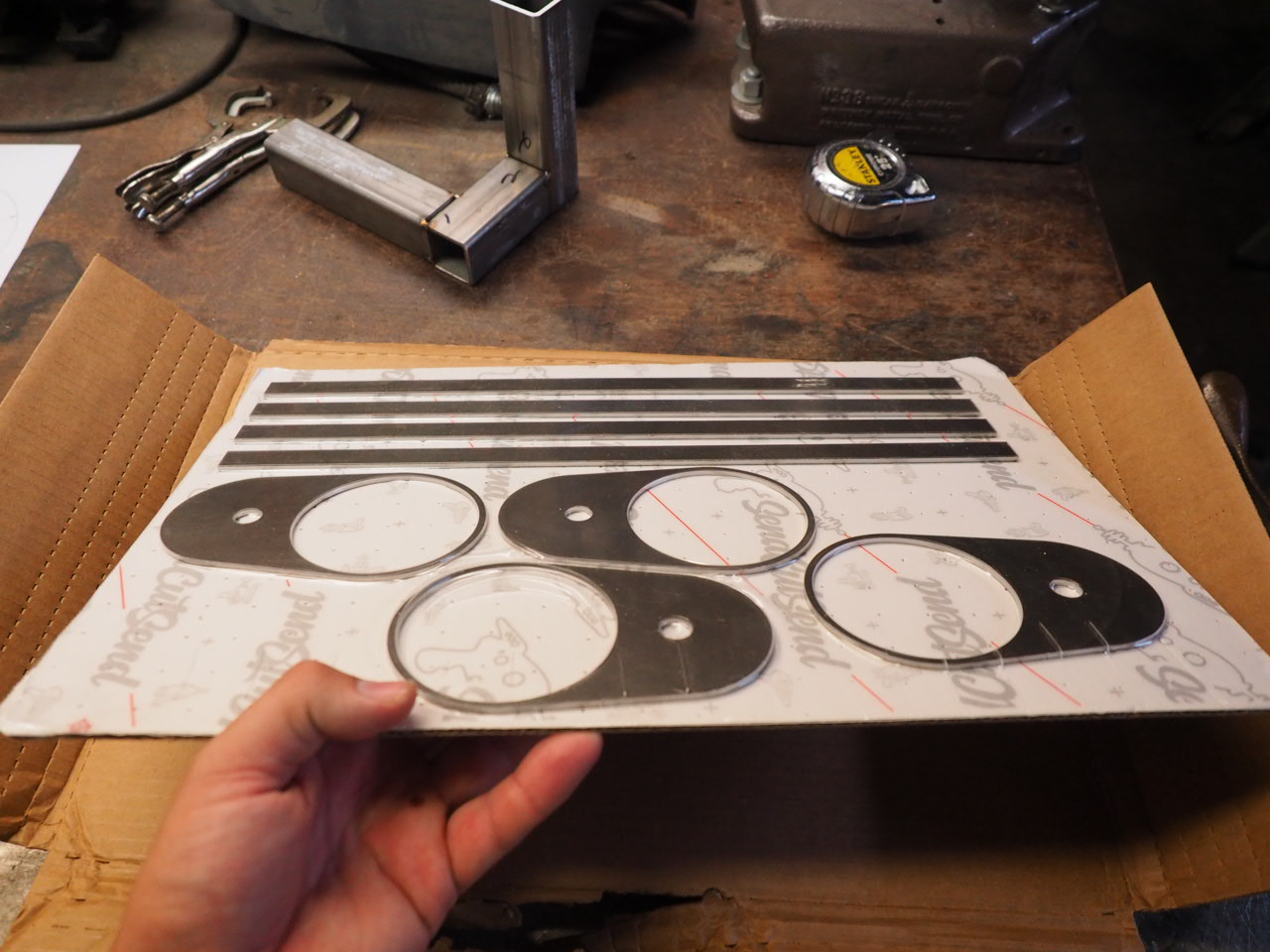

I've received the parts today in the mail!

Included was a brochure with information on the capabilities of SendCutSend.

They even sent a nice decal!

The parts are vacuum sealed to a cardboard sheet like a set of automotive gaskets.

The cuts are very clean!

No real burrs are present. There was an option at checkout to save 5% by declining any kind of post processing or deburring. I took advantage of that savings. Laser cut parts should not really need any significant deburring.

As far as the dimensions, they are pretty good. I only checked one of each part and only with a caliper but the round part is a bit better than the strip. All the numbers on the round part were within a few thousandths of the drawing.

The strip was a little worse. It was dimensioned at 0.620" wide for the entire length of 16". What I measured was 0.621" on one end, 0.611" on the other end and 0.606" in the middle. Maybe there was enough heat input on a long and narrow part to cause some warpage during cutting?

To be honest I'm a little disappointed in the variation but for what I'm making it won't matter. I don't fault the company for this variation, it's probably just a product of the design on my part.

Overall I'm super happy! This is definitely a contact that has made it into my favorites. I'll be calling on them again in the future for sure!

I've received the parts today in the mail!

Included was a brochure with information on the capabilities of SendCutSend.

They even sent a nice decal!

The parts are vacuum sealed to a cardboard sheet like a set of automotive gaskets.

The cuts are very clean!

No real burrs are present. There was an option at checkout to save 5% by declining any kind of post processing or deburring. I took advantage of that savings. Laser cut parts should not really need any significant deburring.

As far as the dimensions, they are pretty good. I only checked one of each part and only with a caliper but the round part is a bit better than the strip. All the numbers on the round part were within a few thousandths of the drawing.

The strip was a little worse. It was dimensioned at 0.620" wide for the entire length of 16". What I measured was 0.621" on one end, 0.611" on the other end and 0.606" in the middle. Maybe there was enough heat input on a long and narrow part to cause some warpage during cutting?

To be honest I'm a little disappointed in the variation but for what I'm making it won't matter. I don't fault the company for this variation, it's probably just a product of the design on my part.

Overall I'm super happy! This is definitely a contact that has made it into my favorites. I'll be calling on them again in the future for sure!

- Joined

- Feb 5, 2018

- Messages

- 637

I have cut a lot of parts on a laser at work, literally 10's of thousands over the years. You will see some variation in a long skinny part like that. One way to help is to make a multi blank that has several parts cut and tabbed together. You can easily bend them to separate them but you will have burr.

Also on the very nice edge on those cuts. Part of that is the operator had the machine adjusted and cutting good. When they are a little off and making you pull your hair out trying to get them cutting nice. Sometimes they look like the parts were cut with a cutting torch with a bad tip.

This is a great opportunity for us hobby guys to have this available.

Joe

Also on the very nice edge on those cuts. Part of that is the operator had the machine adjusted and cutting good. When they are a little off and making you pull your hair out trying to get them cutting nice. Sometimes they look like the parts were cut with a cutting torch with a bad tip.

This is a great opportunity for us hobby guys to have this available.

Joe

- Joined

- Sep 7, 2019

- Messages

- 674

Thanks for the insight, man! I was hoping someone with experience would chime in!

I remember back in welding school days they taught us that if you need to make a long torch cut with little distortion you could make a kind of dotted line. Cut 10" skip 3" and repeat or something like that. Let it cool and finish it off. Should minimize warping. I didn't think it would be an issue with laser since the total heat input is so much less than O/A cutting. And the heat affected zone is so tiny on a laser cut.

Probably the best way to make long strips is by shearing.

I remember back in welding school days they taught us that if you need to make a long torch cut with little distortion you could make a kind of dotted line. Cut 10" skip 3" and repeat or something like that. Let it cool and finish it off. Should minimize warping. I didn't think it would be an issue with laser since the total heat input is so much less than O/A cutting. And the heat affected zone is so tiny on a laser cut.

Probably the best way to make long strips is by shearing.