Hi guys, I just purchased this little lathe and it needs some love for sure. It came with a few bits of tooling and such and is missing a few pieces but it is useable as is, I just need to decide if i'm going to do a full restoration or not. The bearings and ways seem totally fine and all the gears still look pretty good, as do the extras that came with it.

Anyways, as I'm brand new to lathes, please excuse me if I use the incorrect terminology, ha ha.

I turned the compound slide handle until it came out of the brass barrel nut at the end. I cant seem to get it back in now. Any ideas?

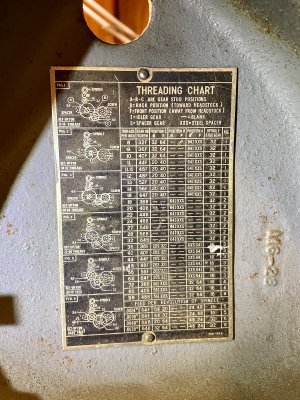

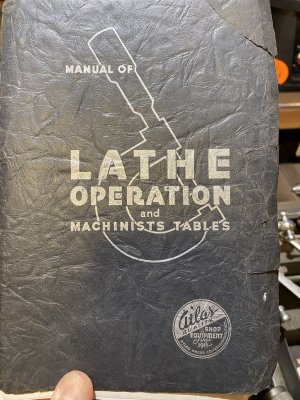

Here are a few pictures so you can all see this little thing. Pretty sure that the estate I purchased it from was the original owner based on all the things that came with it.

Thanks, -John

Anyways, as I'm brand new to lathes, please excuse me if I use the incorrect terminology, ha ha.

I turned the compound slide handle until it came out of the brass barrel nut at the end. I cant seem to get it back in now. Any ideas?

Here are a few pictures so you can all see this little thing. Pretty sure that the estate I purchased it from was the original owner based on all the things that came with it.

Thanks, -John

Attachments

-

IMG-3344.jpg2.7 MB · Views: 29

IMG-3344.jpg2.7 MB · Views: 29 -

IMG-3346.jpg3.4 MB · Views: 28

IMG-3346.jpg3.4 MB · Views: 28 -

IMG-3347.jpg4.1 MB · Views: 21

IMG-3347.jpg4.1 MB · Views: 21 -

IMG-3349.jpg2.9 MB · Views: 20

IMG-3349.jpg2.9 MB · Views: 20 -

IMG-3350.jpg4.5 MB · Views: 19

IMG-3350.jpg4.5 MB · Views: 19 -

IMG-3351.jpg3.9 MB · Views: 18

IMG-3351.jpg3.9 MB · Views: 18 -

IMG-3353.jpg5.9 MB · Views: 20

IMG-3353.jpg5.9 MB · Views: 20 -

IMG-3355.jpg3.4 MB · Views: 25

IMG-3355.jpg3.4 MB · Views: 25 -

IMG-3361.jpg3.4 MB · Views: 26

IMG-3361.jpg3.4 MB · Views: 26 -

IMG-3362.jpg4.3 MB · Views: 29

IMG-3362.jpg4.3 MB · Views: 29