- Joined

- Sep 20, 2012

- Messages

- 560

Last edited:

:thumbsup::thumbsup: Looking good. Get us another picture when she is all dolled up.

Nice press, you can get the parts list on owwm. I've done 2 of them so far, and built a puller block for extra speed changes. I also had the base and table of one of them surface ground, it was very far off being flat.

Excellent find on the Atlas, it is worthy of gloating!!!

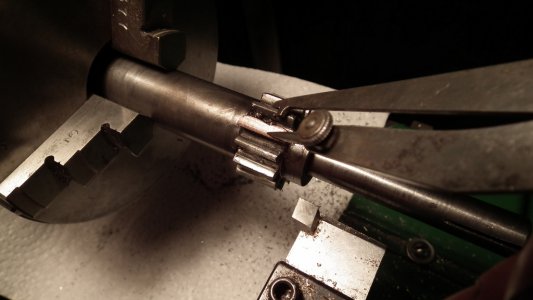

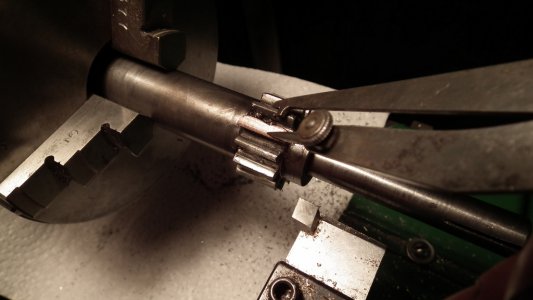

This afternoons work...

View attachment 59654

Yep, mine has a warped table too, my mate has a mill...thanks for pointing me to the owwm site, can't imagine how I managed to miss that mine of info in all my googling..:thumbzup:

Not too worthy, found two broken teeth on the quill actuator gear, and the balls are gone from the bearing at top of the quill, these must been slack and fallen out when the drill was laying on it's side, plenty of grease in there so might come across them soon!

Bernard

My presses are 42b's but your looks to be a 52. Get new bearings, and see if you can surface grind instead of milling the table. Too bad about the teeth on the gear, how the heck does someone break that?

I paint all my tools with caliper paint, works great, cutting fluid does not peel the paint. Pull the spindle out and check the bushings, might need new ones if the things has been abused.