I posted in your recent thread requesting such.OK. First, for many years, I used to every now and again ask for a bottom view photo (from outside, inside or both) of the headstock castings from various models of the 10" and 12" Atlas and Craftsman lathes.

Request for photos of the bottom of the Atlas 10" and early Craftsman 12" headstock.

Request for photos of the bottom of the Atlas 10" and early (i.e., 3/8" bed) Craftsman 12" headstock.

www.hobby-machinist.com

www.hobby-machinist.com

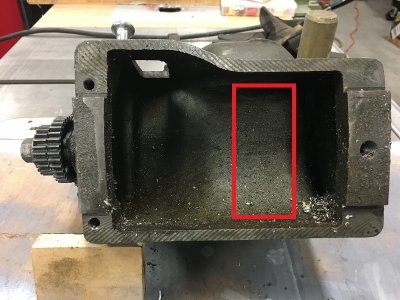

Robert, I'm going to have to take back part of what I said above. It does look possible to cut a window in the old style headstock casting for bottom exit belts. Whether it's advisable may be another matter because it may compromise the structural integrity of the headstock, but you need at least 3 1/4" and better 3 1/2" opening for belt clearance from the 3" 2-groove pulley. If you mounted the headstock on a mill with along cutter, you could punch a hole approximately where shown below. You would also have to cut similar reliefs in the bed was and bottom rib under this location on the headstock.......There's absolutely no way the headstock casting could accommodate bottom exit of the belts, and certainly not placing the back gears underneath the spindle if that is part of the desired conversion.

Now, placing the back gears under the spindle is another matter. You need to cut away so much of the headstock it would certainly be compromised and you really don't have much material for the back gear shaft and then you would need an engagement mechanism for the back gear and there just isn't room so even though you may get the belts out the bottom the back gears would still....well, in back.

-My 2 cents

Best,

Kelly