-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Automatic Feed Stop

- Thread starter Billh50

- Start date

- Joined

- Jan 26, 2015

- Messages

- 1,939

Update on progress.

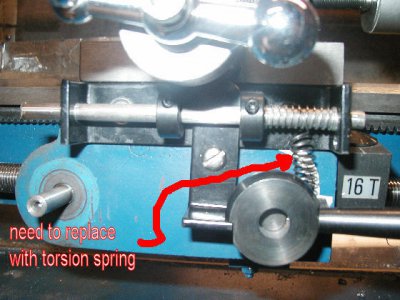

Just did a quick trial with a jury rigged solid stop. The shut off works fine for normal feed rates and fine pitched threading. But as the threading gets somewhat coarse the spring that returns the handle to the neutral position does not have enough strength to disengage the split nuts. Evidently the pressures against the split nut is greater as the pitch increases. I am going to try a torsion spring instead as I can get more spring pressure that way. Once I get everything working good I will have update plans available. This may come in handy for those with mini-lathes and other may be able to alter the plans to suit.

Just did a quick trial with a jury rigged solid stop. The shut off works fine for normal feed rates and fine pitched threading. But as the threading gets somewhat coarse the spring that returns the handle to the neutral position does not have enough strength to disengage the split nuts. Evidently the pressures against the split nut is greater as the pitch increases. I am going to try a torsion spring instead as I can get more spring pressure that way. Once I get everything working good I will have update plans available. This may come in handy for those with mini-lathes and other may be able to alter the plans to suit.

- Joined

- Jan 25, 2015

- Messages

- 2,558

Very interesting, you've got my brain turning on a design of my own now.

I would like to build an automatic stop just to prevent "newbie" crashes into the chuck if nothing else.....

I would like to build an automatic stop just to prevent "newbie" crashes into the chuck if nothing else.....

- Joined

- Jan 26, 2015

- Messages

- 1,939

that was why I started this. I came close a couple times to hitting a shoulder. I know it will work for me once I get the right spring tension because it works great at slow feeds. And once it's done I should be able to repeat the stop position every time.

- Joined

- Oct 24, 2014

- Messages

- 208

Having worked in a production shop on Porter-Cable lathes many years ago, I very well remember that the mechanical feed stops supplied with the lathes from the factory did have issues with repeatability. The heavier the cut, and even the duller the tool became in production, the more stress on the feed engagement gear/dog? and the further it would hang on till disengaging. We had to have the same depth cut on each pass to ensure there were no disasters!! I have a homemade stop on the halfnut lever on my Chinese lathe but I don't really trust it. If I was to build an auto feed stop for the feed lever, I would use a micro switch and a solenoid to disengage. We had used a similar system on some Logan lathes, and the disengage point was very stable, an air cylinder was used not a solenoid, but the stop point was very reliable

:makingdecision:

:makingdecision:

- Joined

- Mar 25, 2013

- Messages

- 4,653

Having worked in a production shop on Porter-Cable lathes many years ago, I very well remember that the mechanical feed stops supplied with the lathes from the factory did have issues with repeatability. The heavier the cut, and even the duller the tool became in production, the more stress on the feed engagement gear/dog? and the further it would hang on till disengaging. We had to have the same depth cut on each pass to ensure there were no disasters!! I have a homemade stop on the halfnut lever on my Chinese lathe but I don't really trust it. If I was to build an auto feed stop for the feed lever, I would use a micro switch and a solenoid to disengage. We had used a similar system on some Logan lathes, and the disengage point was very stable, an air cylinder was used not a solenoid, but the stop point was very reliable

:makingdecision:

So would you use a 120v control circuit with a heavy duty microswitch? You could use a lower voltage control circuit and a Triac or something similar. Can any of you electrical gurus suggest a schematic?

R

- Joined

- Oct 24, 2014

- Messages

- 208

On the old systems it was straight 110 vac. The micro sw used was a " BZE6-2RN" 15 amp ac, 500 ma dc. If I were doing it, I'd prob go with DC and have a capacitor discharge thru the solenoid leaving a small current running as long as the sw was still actuated. Shouldn't be too much to it.

That particular microsw in it's housing is expensive new, but can be had used and when you take it apart there is a conventional microsw inside that can be replaced with a new one.

Guess I've been thinking about this in my sleep for a while :>))

:nervous:

That particular microsw in it's housing is expensive new, but can be had used and when you take it apart there is a conventional microsw inside that can be replaced with a new one.

Guess I've been thinking about this in my sleep for a while :>))

:nervous: