Hi Guys,

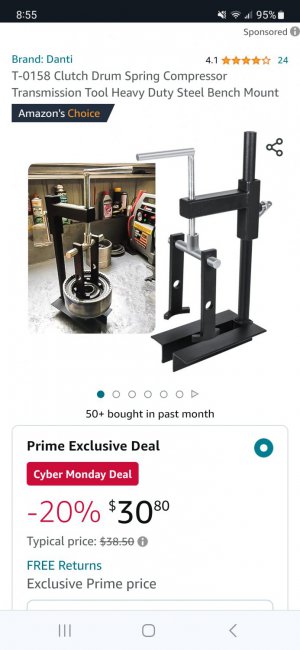

The 2004 ram1500 auto transmission is hesitating a bit. Has anyone done a automatic transmission rebuild. If anyone can share a ray of light on what tools does one need to do it?

I have most mechanical tools and extractors but never opened an automatic transmission before.

Tim

The 2004 ram1500 auto transmission is hesitating a bit. Has anyone done a automatic transmission rebuild. If anyone can share a ray of light on what tools does one need to do it?

I have most mechanical tools and extractors but never opened an automatic transmission before.

Tim