- Joined

- Jan 25, 2015

- Messages

- 2,558

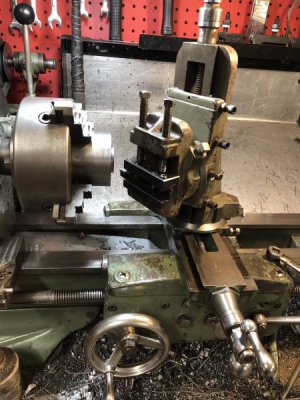

So I finally got to where i could stand to look at it again.

A closer examination of the break reveals it had been propagating for a long time. From the looks of the origin point, longer than I have had it. Crack started in the middle of the piece somehow and worked it's way out.

It was a ticking bomb and only a matter of time before it would go "kaboom".

A closer examination of the break reveals it had been propagating for a long time. From the looks of the origin point, longer than I have had it. Crack started in the middle of the piece somehow and worked it's way out.

It was a ticking bomb and only a matter of time before it would go "kaboom".

Last edited: