- Joined

- Jan 20, 2018

- Messages

- 5,623

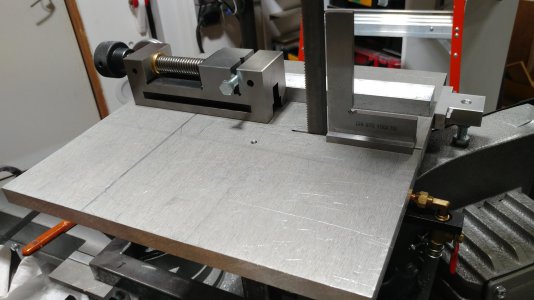

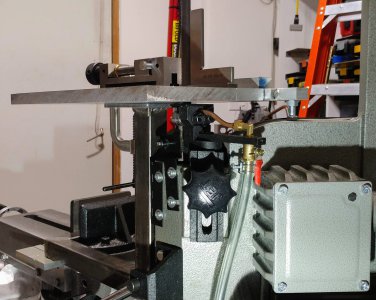

The HF 4x6 is definitely worth buying. It's one of the few tools I bought new. Hold out for a sale or 20% coupon though, mine was about $200. Unlike many of the complaints, mine cut square and straight right from the box. I've made several useful mods, including the flip-down table for vertical cutting, which is one of the slickest and most useful mods I've seen.