To answer some questions:

No, it has not run since I've had it.

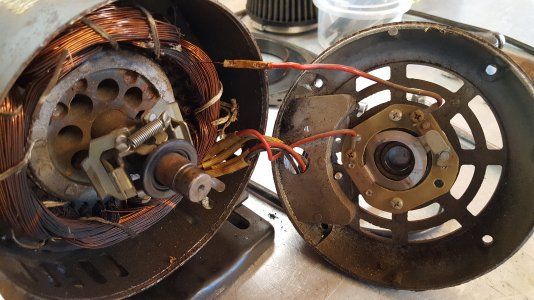

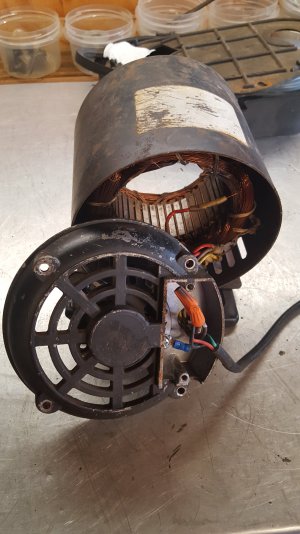

Everything mechanically turns fine. The band saw blade and wheels, the pulley on the "blade" side. the armature when it was assembled. Nothing was binding.

There is no "hum" when the switch was on. It was a simple wall mount type light switch, and tested as good.

The red wire with the spade connector that is loose was connected; I took it off to take strain off the wire to the windings.

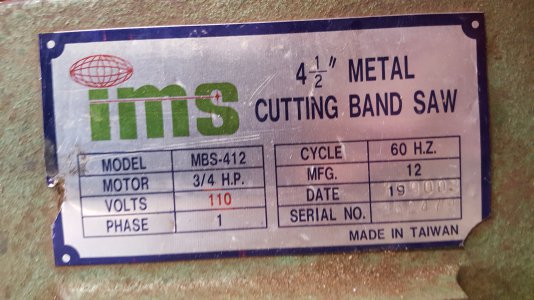

There is no readable sticker or plate on the motor. The one I took was on the saw itself (I know it's not the same, but it's the best I have and pixels are cheap). The motor does not seem to be "wrong" for the saw, but I have no idea if it is original or not. I believe it is, though.

20191111_123400.jpg3.8 MB · Views: 33

20191111_123400.jpg3.8 MB · Views: 33 20191111_123409.jpg3.8 MB · Views: 31

20191111_123409.jpg3.8 MB · Views: 31 20191111_123414.jpg4.1 MB · Views: 29

20191111_123414.jpg4.1 MB · Views: 29 20191111_124003.jpg3.6 MB · Views: 30

20191111_124003.jpg3.6 MB · Views: 30 20191209_120230.jpg1.8 MB · Views: 30

20191209_120230.jpg1.8 MB · Views: 30 20191209_120321.jpg1.6 MB · Views: 32

20191209_120321.jpg1.6 MB · Views: 32 20191209_120410.jpg1.6 MB · Views: 31

20191209_120410.jpg1.6 MB · Views: 31 20191209_120436.jpg1.6 MB · Views: 29

20191209_120436.jpg1.6 MB · Views: 29 20191209_120459.jpg1.7 MB · Views: 30

20191209_120459.jpg1.7 MB · Views: 30 20191209_120529.jpg1.7 MB · Views: 33

20191209_120529.jpg1.7 MB · Views: 33 20191209_120610.jpg2 MB · Views: 32

20191209_120610.jpg2 MB · Views: 32