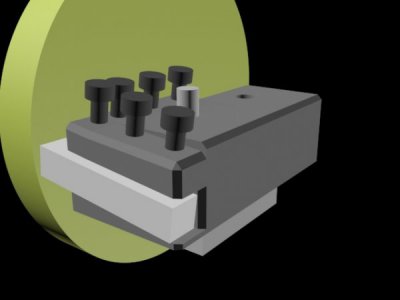

Just doodling on my laptop in 3dsmax and I think I've come up with something, although it's set at 7 degrees so angles are none adjustable for clearances and 1 rake angle..

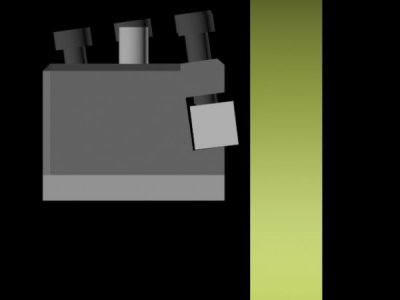

This is a Perspective shot and reference is a 150mm grinding wheel which will be arbored on the lathe, cross slide top is 50x50mm ( Sieg C3 max 2600rpm ) and the lathe tooling for the Sieg

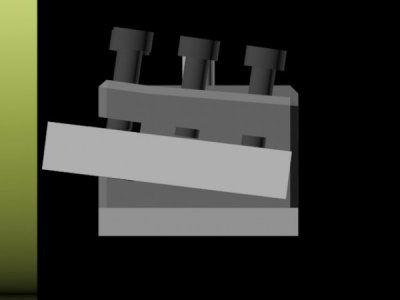

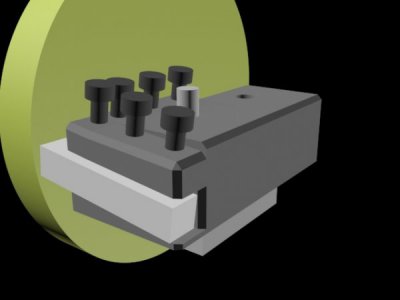

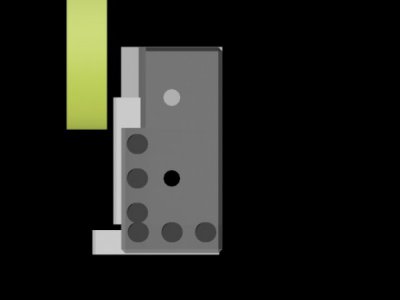

Front Clearance from front

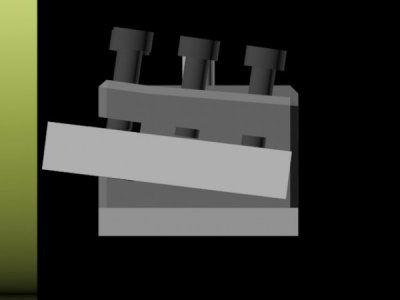

and top, notice the grinder block has 2 through holes for positioning, important for the side clearance because of cross slide travel, top rakes are done by changing the topslide compound angle and ground with the curved edge of the wheel not the face, tool bit extended if needed, this will be cutting above wheel center so the rake could be severe!

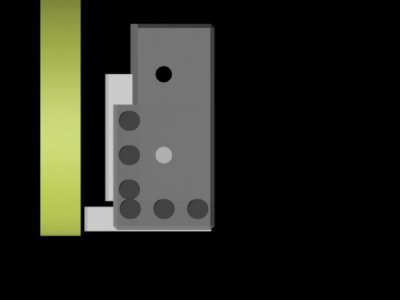

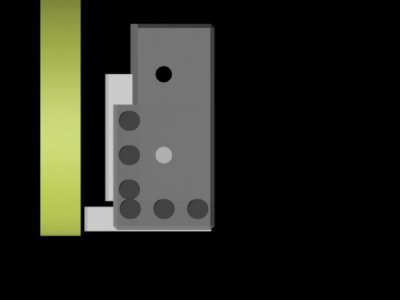

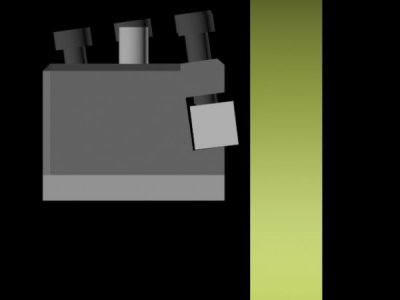

Side Clearance Top view using the other through hole to hold the block 40mm further forward so the tool can reach the edge of the grinding wheel

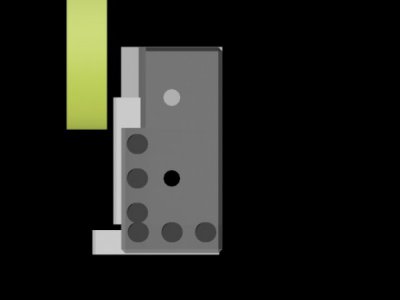

Side Clearance back view

has anyone got any thoughts on this? all it would take ( sizing for my fastest lathe ) is a block of steel 120mm Long, 50mm wide and 40mm thick plus 6x M6 Cap screws, plus a bit of milling on the Myford VMC

This is a Perspective shot and reference is a 150mm grinding wheel which will be arbored on the lathe, cross slide top is 50x50mm ( Sieg C3 max 2600rpm ) and the lathe tooling for the Sieg

Front Clearance from front

and top, notice the grinder block has 2 through holes for positioning, important for the side clearance because of cross slide travel, top rakes are done by changing the topslide compound angle and ground with the curved edge of the wheel not the face, tool bit extended if needed, this will be cutting above wheel center so the rake could be severe!

Side Clearance Top view using the other through hole to hold the block 40mm further forward so the tool can reach the edge of the grinding wheel

Side Clearance back view

has anyone got any thoughts on this? all it would take ( sizing for my fastest lathe ) is a block of steel 120mm Long, 50mm wide and 40mm thick plus 6x M6 Cap screws, plus a bit of milling on the Myford VMC