- Joined

- Dec 7, 2015

- Messages

- 519

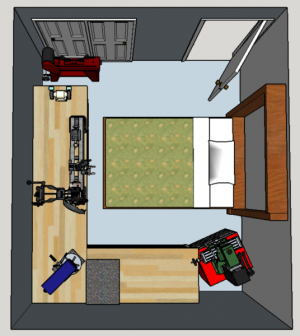

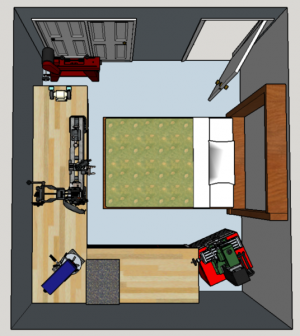

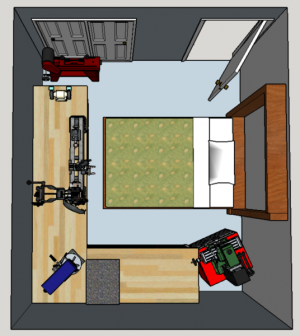

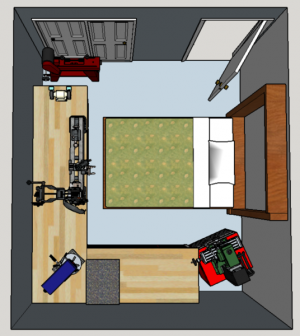

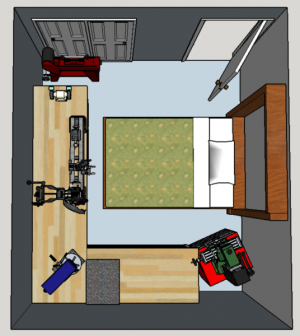

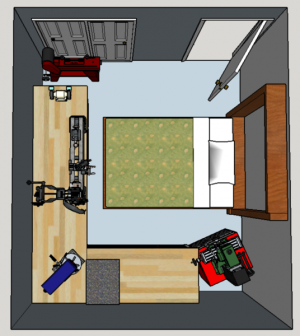

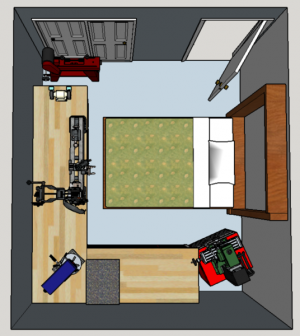

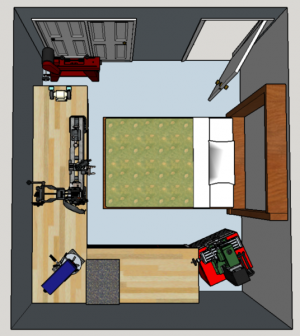

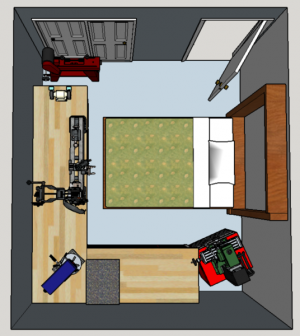

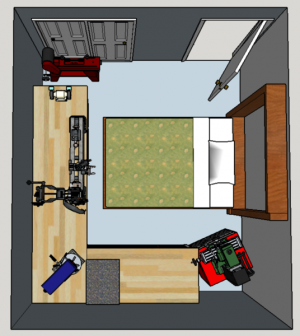

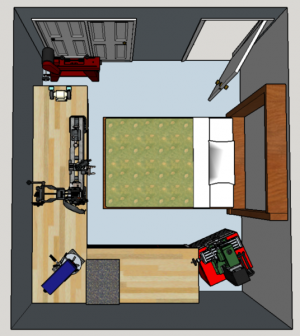

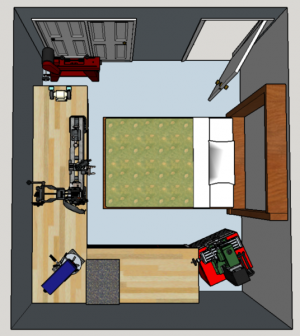

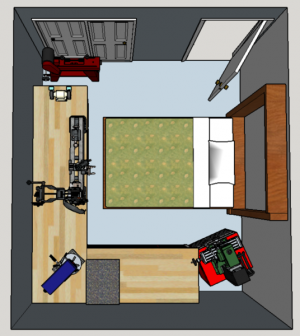

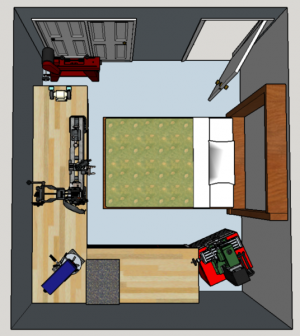

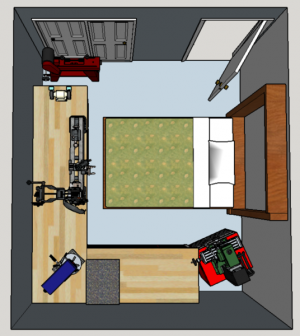

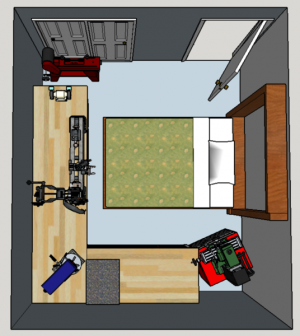

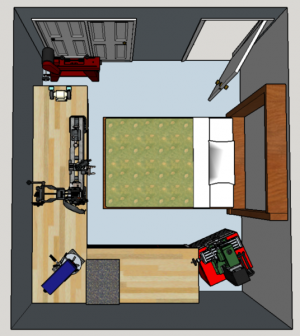

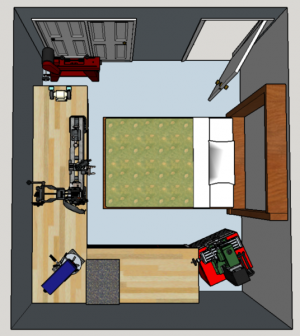

Starting this thread to document a new machine shop I'm putting together in my very seldom used spare bedroom. The intention is that the room is primarily a machine shop, but can be converted into a guest bedroom when needed. This room is 10.5' x 12' with an additional closet. I'm choosing this bedroom for a number of reasons:

Phase 1: Room prep. I'll paint the ceiling and walls. I'm going to install a 20A recep in the room. The hardwood floor needs refinished, but that almost seems silly when I'm going to be moving in a bunch of heavy machines and getting swarf all over. Instead, I'm considering a floor covering not so different from those floor tiles people put in their fancy garages.

Phase 1.5: Murphy bed. I don't really want to address building the murphy bed right away. It's honestly not a priority project for the build. That said, the bed is in the way... I don't think I'll address this as the second phase, but I'll probably start it while in the middle of Phase 2.

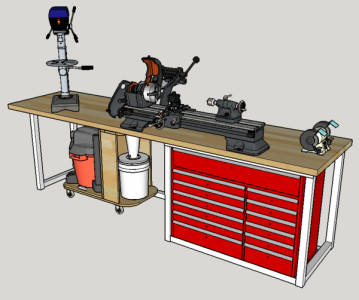

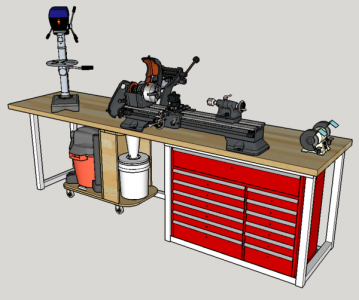

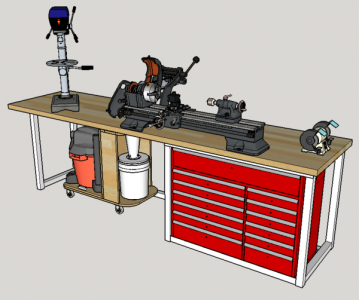

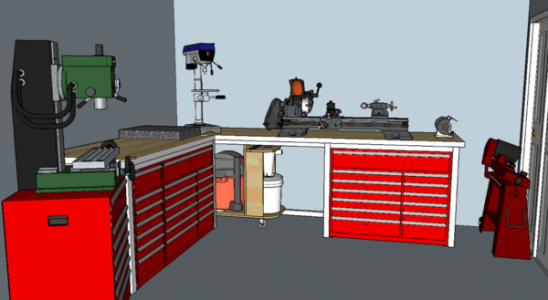

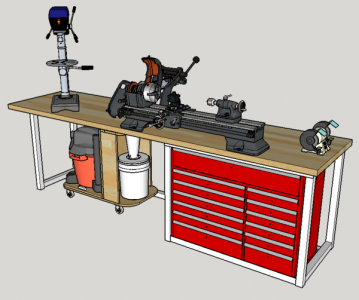

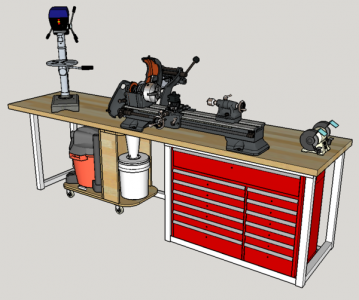

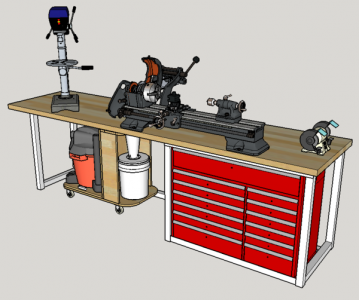

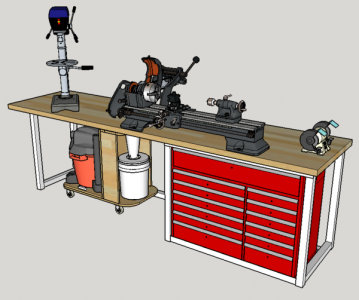

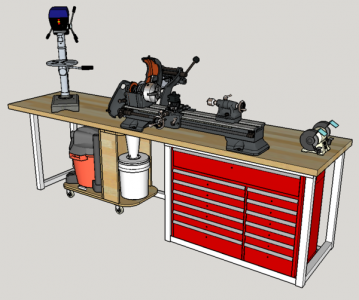

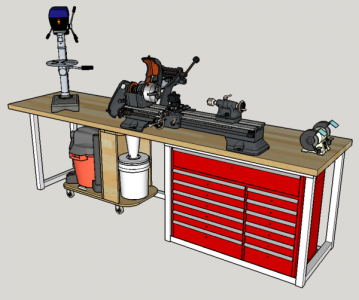

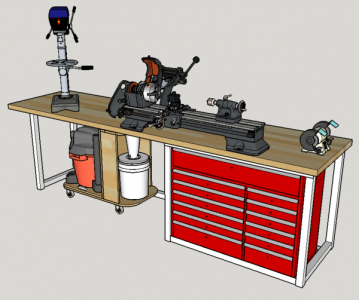

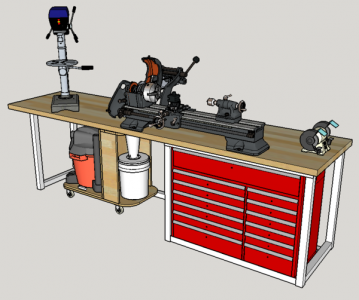

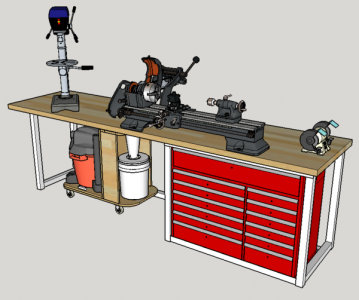

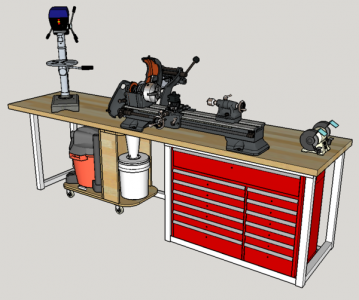

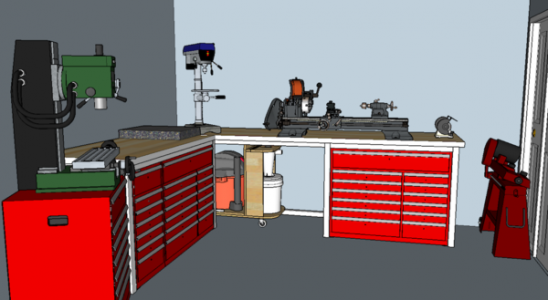

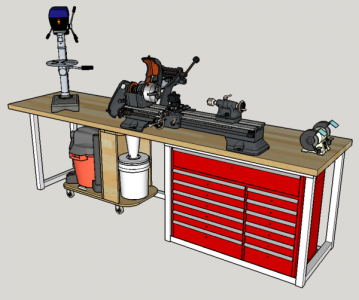

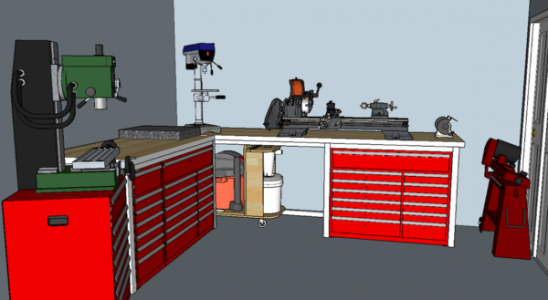

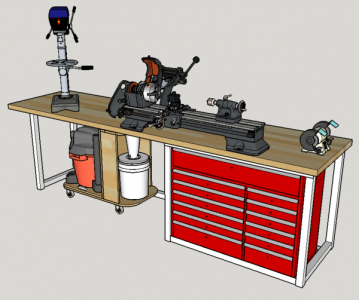

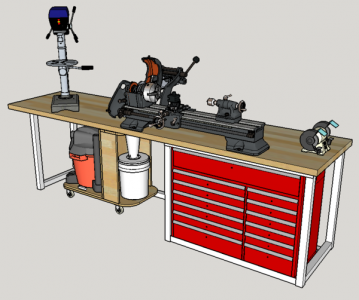

Phase 2: Lathe bench. Tonight I took delivery of a 120" x 30" x 1.75" butcher block maple bench top from Grizzly. It's massive; it's heavy; and it's awesome. I'm beside myself. It's the first purchase I've made for this whole project and I can't wait to get it setup. To do that, I need to fabricate the steel bench to put it on. It's not really a huge project, but it does involve lots of garage time right as it's starting to get super cold. Not my favorite time to be working in the garage. Wrapping up this phase will be my lathe purchase (a South Bend 9A) hopefully in February.

Phase 2.5: Bandsaw/Bench accessories. There's no real building involved with this phase. But the SB 9A has only a 3/4" spindle bore and therefore I'll need a convenient way to turn larger diameter stuff. It seems reasonable that a horizontal bandsaw sets me up well for beginning some turning work. Also included would be a bench grinder for grinding cutting tools- and I'm always on the lookout for a restorable Atlas/South Bend/Walker Turner bench drill press. I don't know if the restoration would be part of this phase or not.

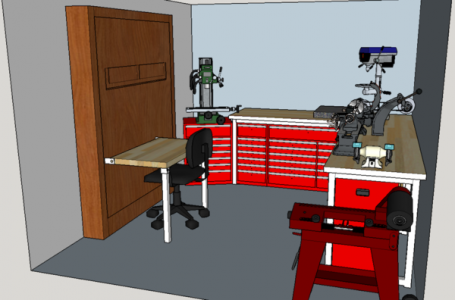

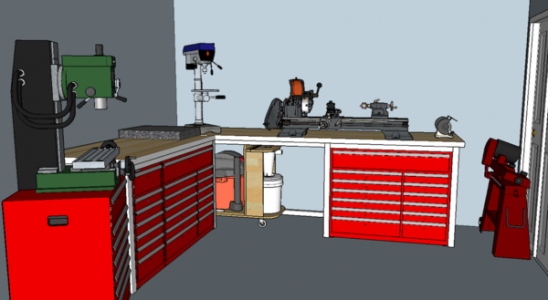

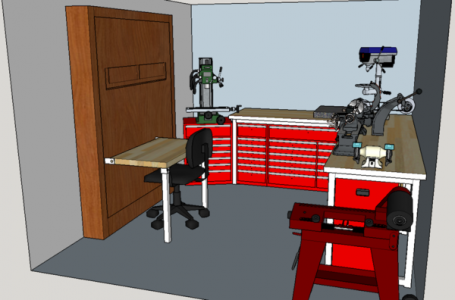

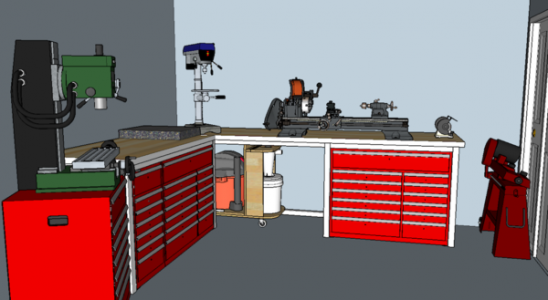

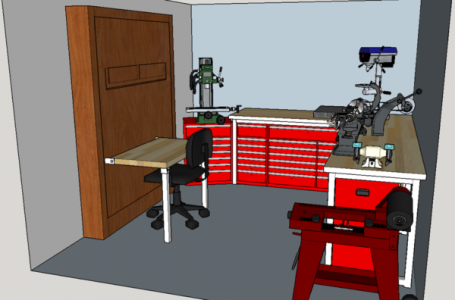

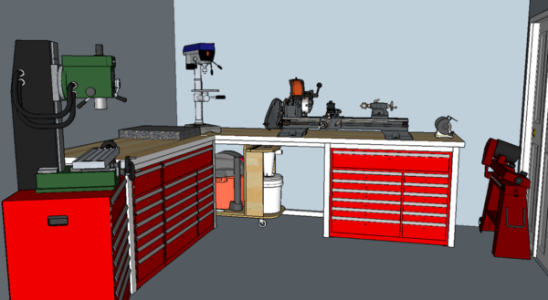

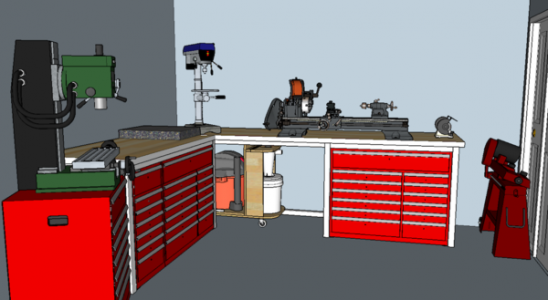

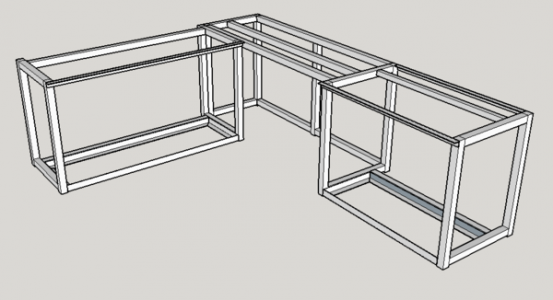

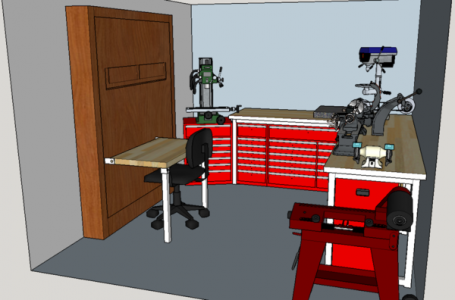

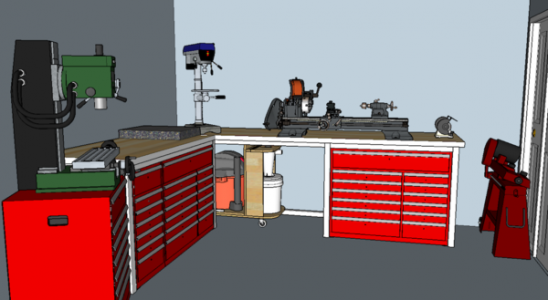

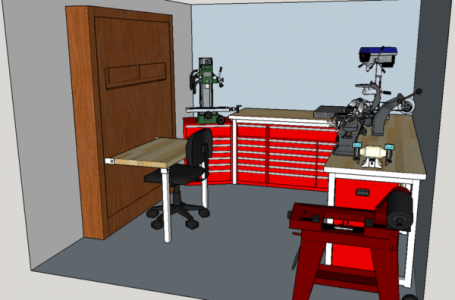

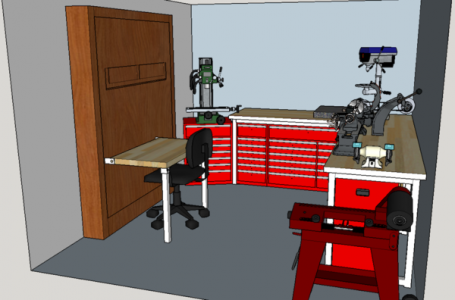

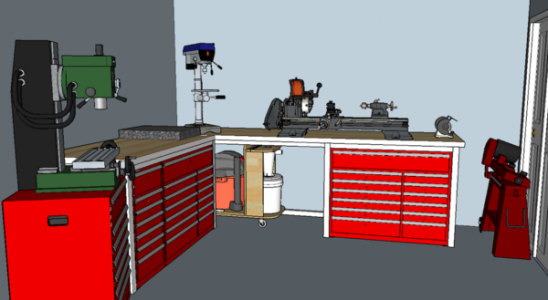

Phase 3: Workbench. This phase will include building the dog leg for the workbench, and purchasing the tool cabinets for the room. This bench is 60" long and serves as an assembly table as well as a convenient place for a surface plate. This might also be a good time to build a workbench into the murphy bed. While the main assembly area will be nice, I'm not convinced that the lack of a toe kick space won't be super annoying. Therefore I'll build a bench into the murphy bed as well that I can pull a chair up to.

Phase 4: Milling machine. This one just has to wait. This project is already going to cost a small fortune. I don't foresee reaching this point at least until next year. But the plan is a PM-25MV or PM-727M mill sitting on top of a Harbor Freight 27" wide cabinet. If I end up getting the heavier mill, I'll enclose the cabinet in a steel frame for better support. Also, I'll likely need to add some blocking in the crawlspace to support this heavier mill.

_______________

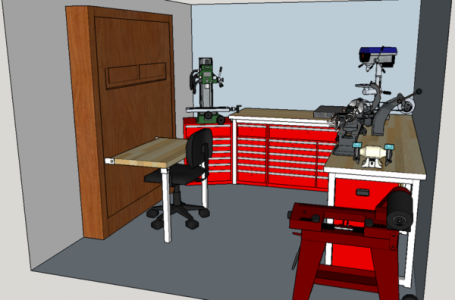

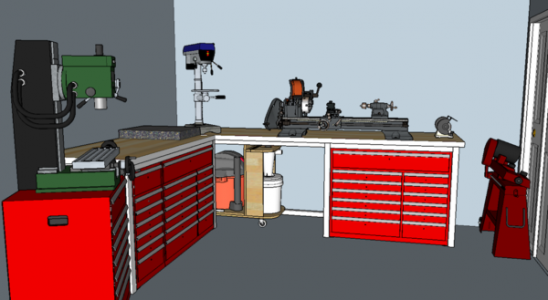

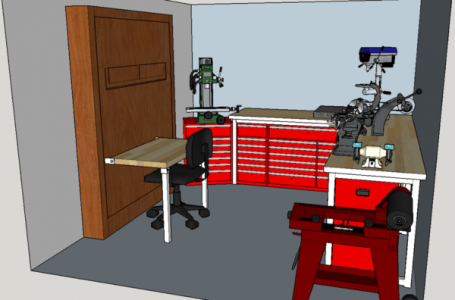

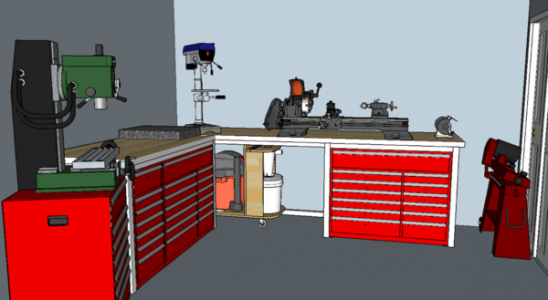

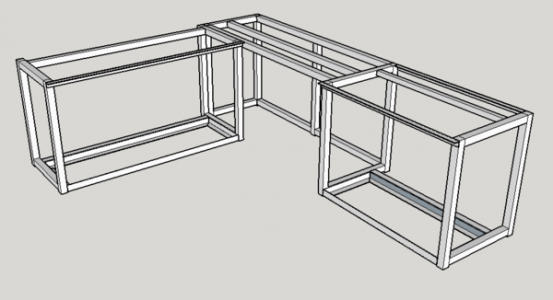

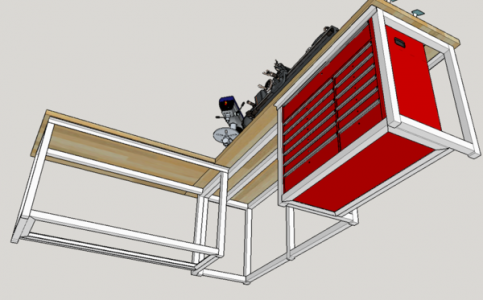

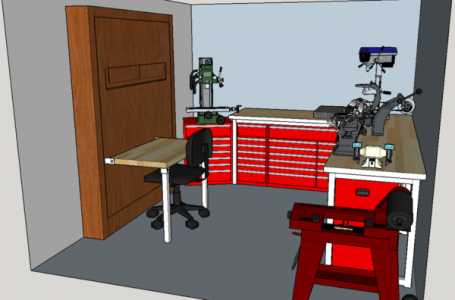

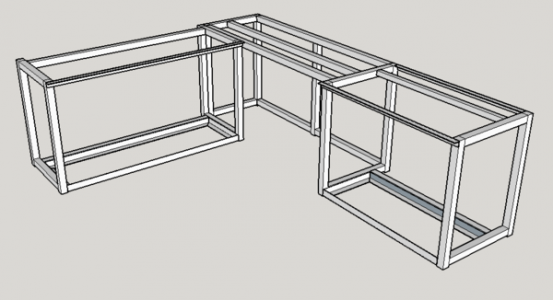

Well- that was a lot of words, but I think typing it out helped me solidify some thoughts and build order. Below you can see my plans (to scale) modeled in Google SketchUp. Enjoy!

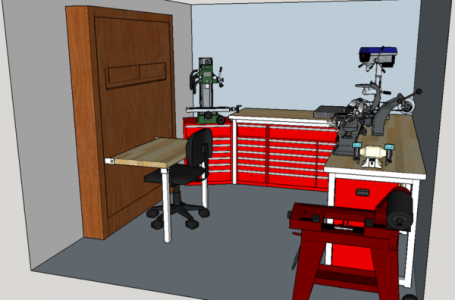

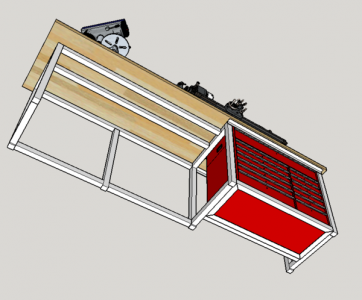

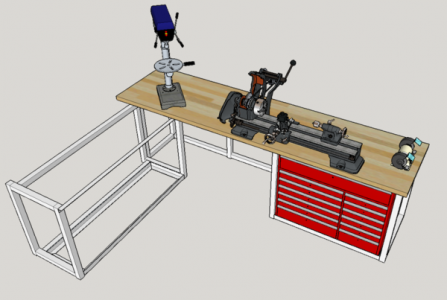

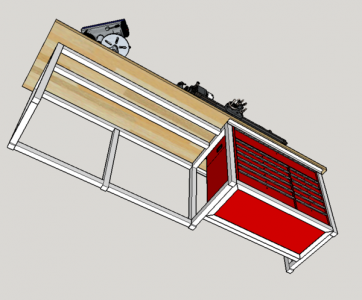

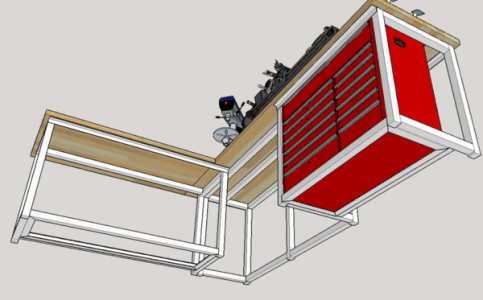

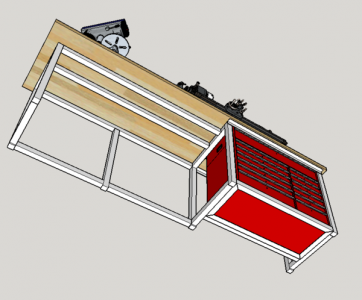

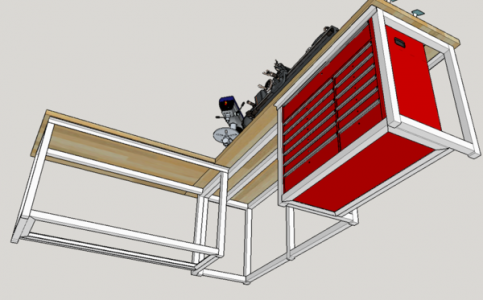

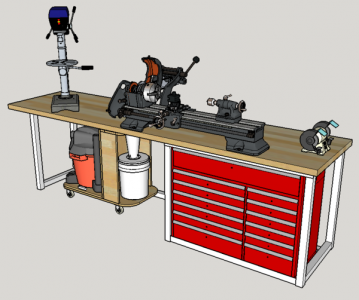

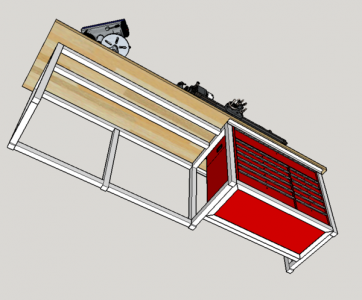

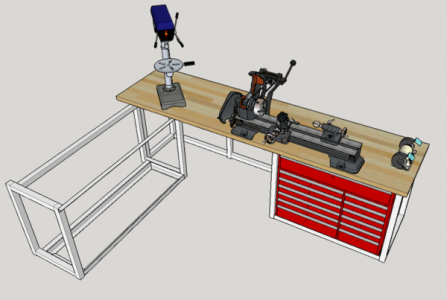

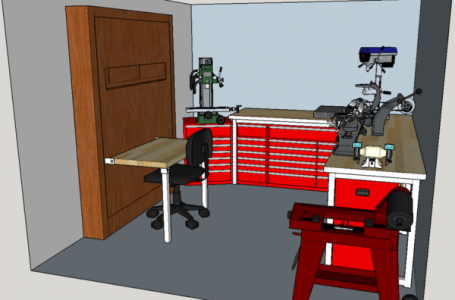

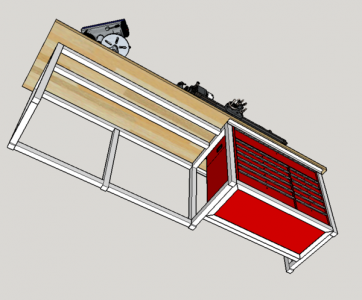

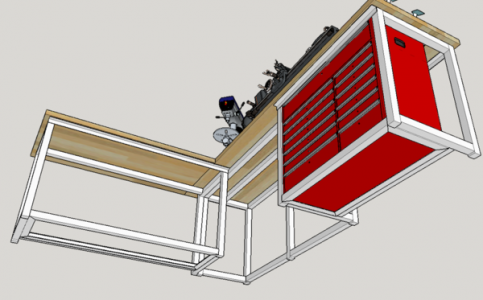

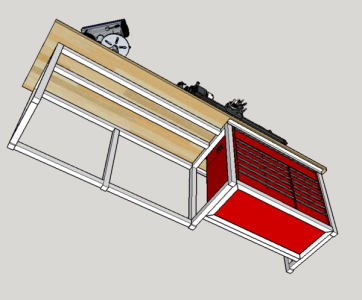

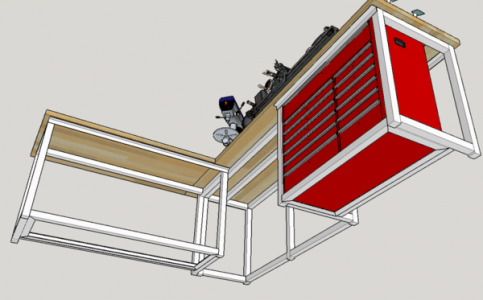

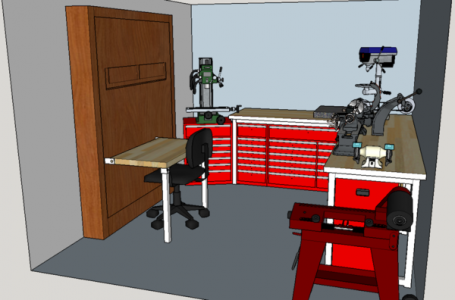

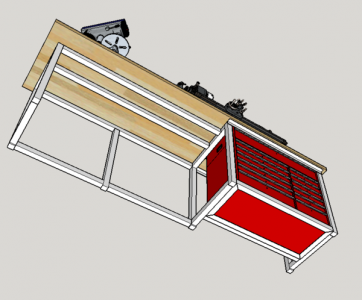

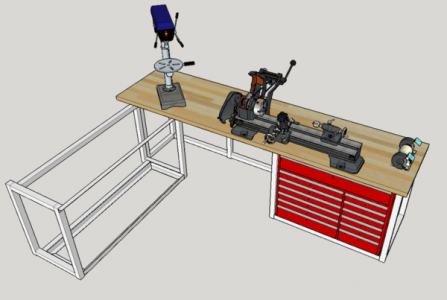

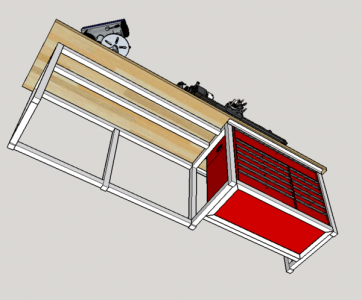

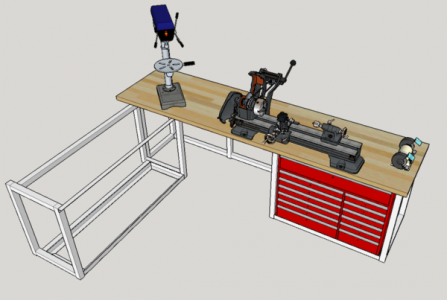

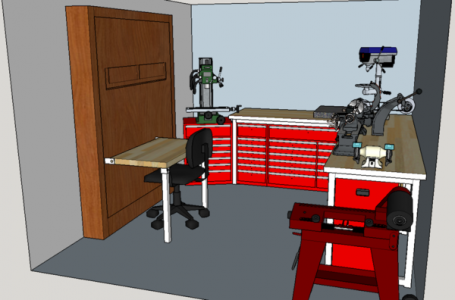

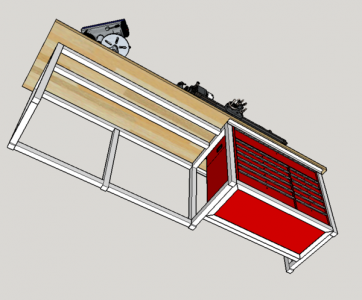

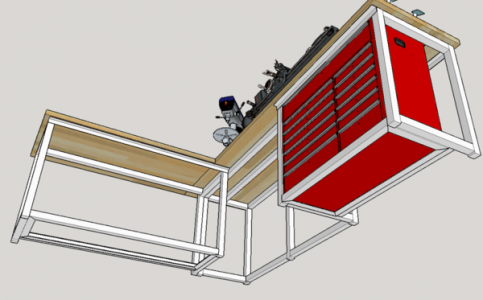

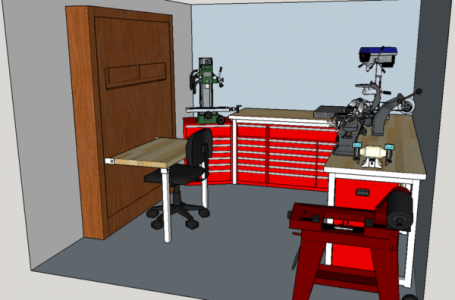

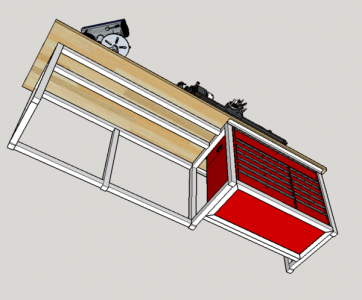

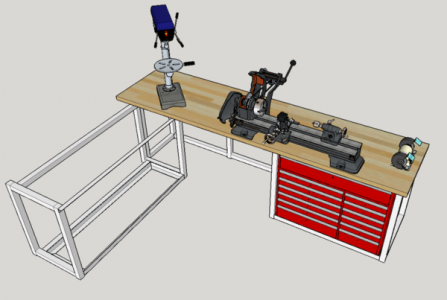

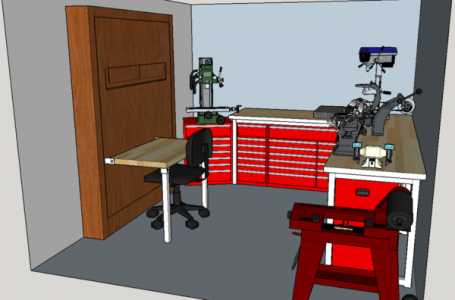

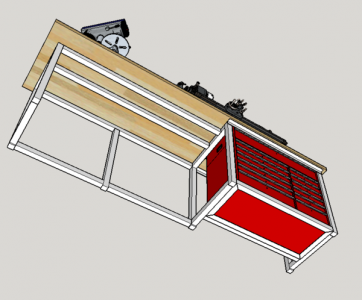

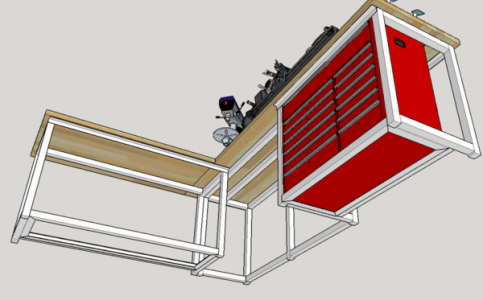

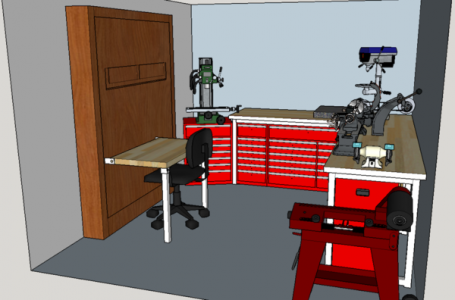

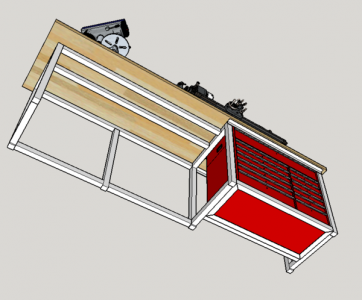

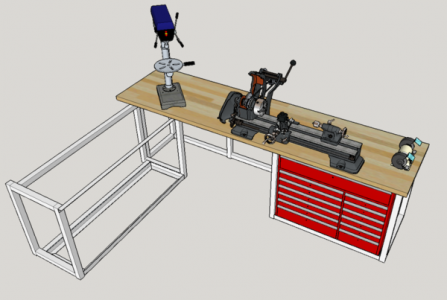

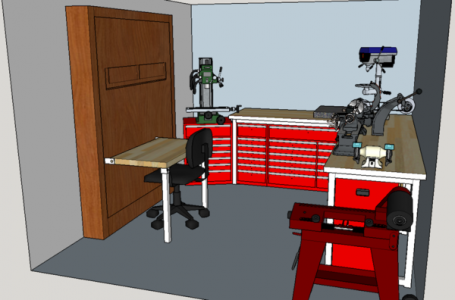

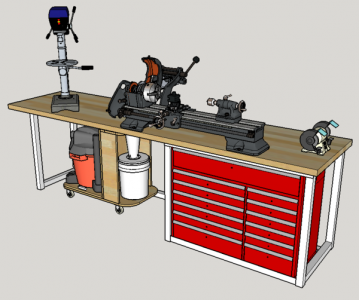

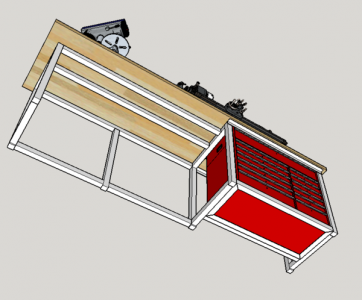

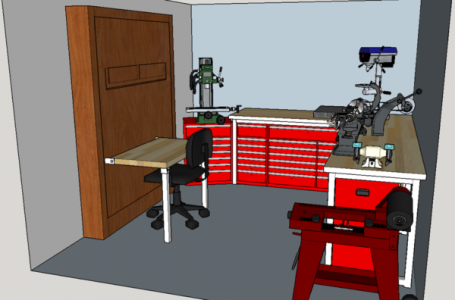

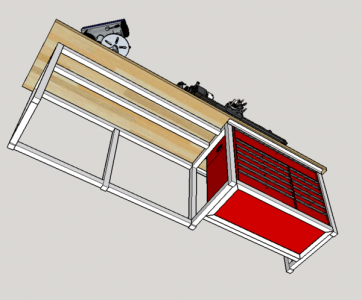

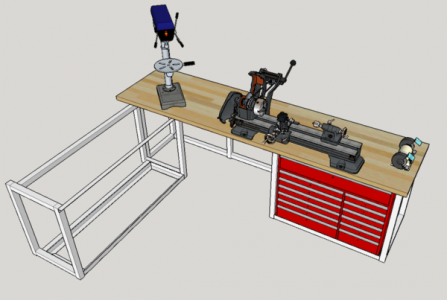

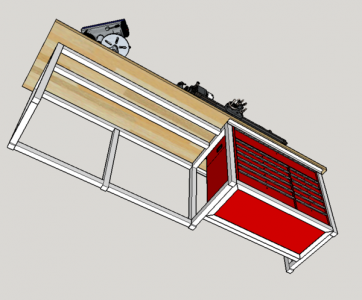

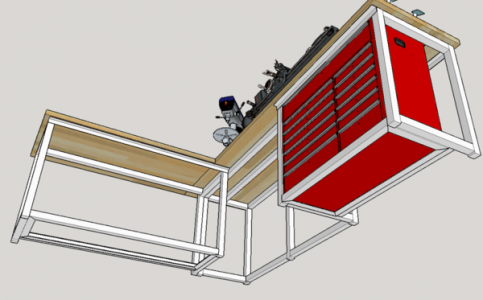

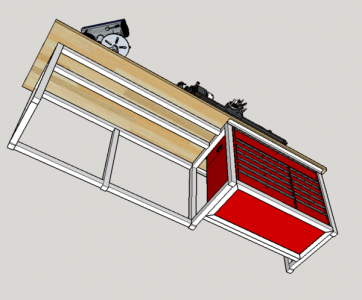

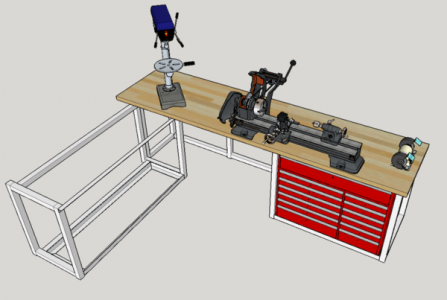

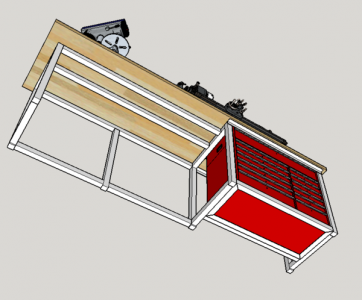

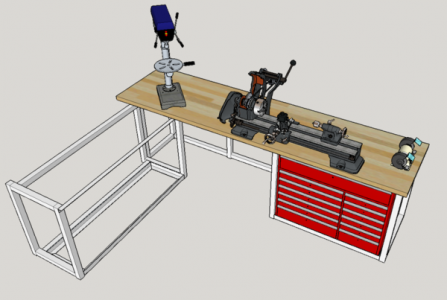

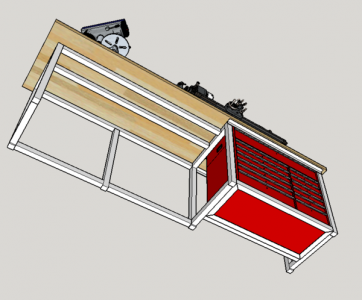

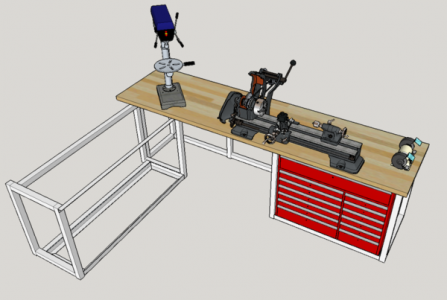

This is the Phase 2 bench:

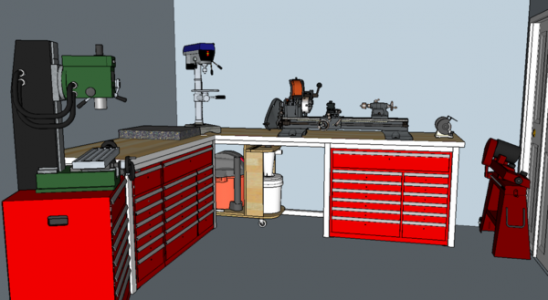

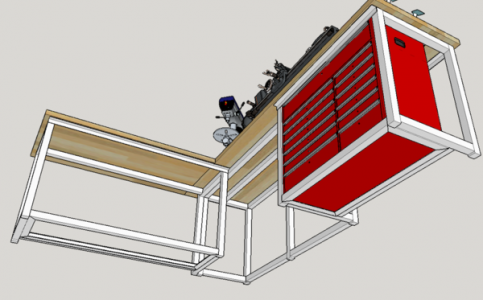

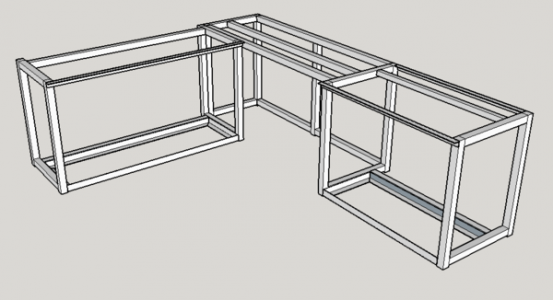

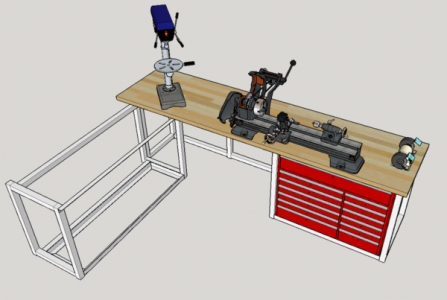

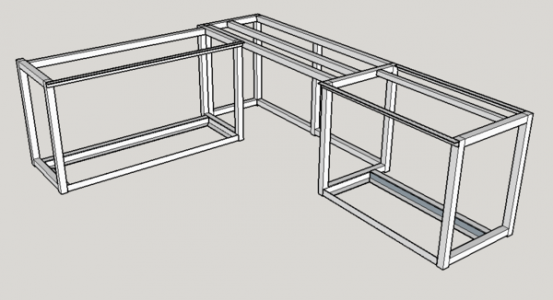

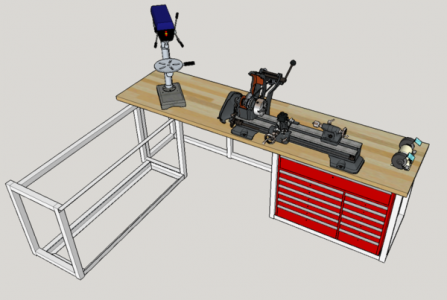

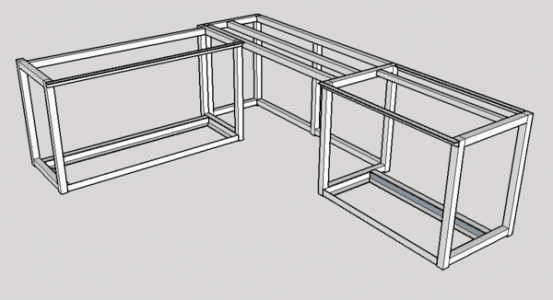

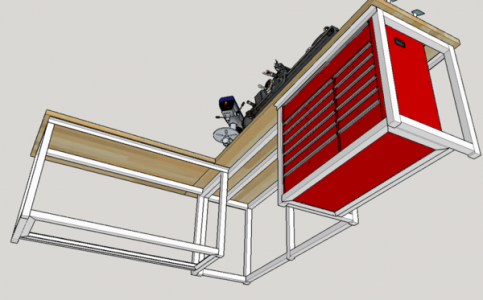

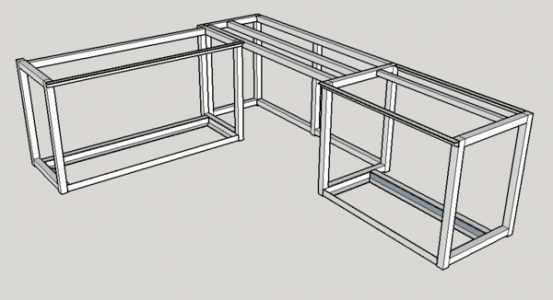

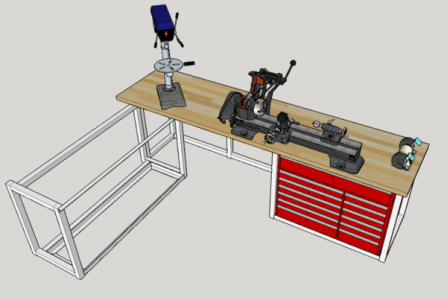

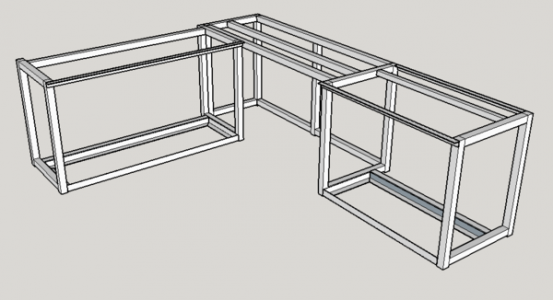

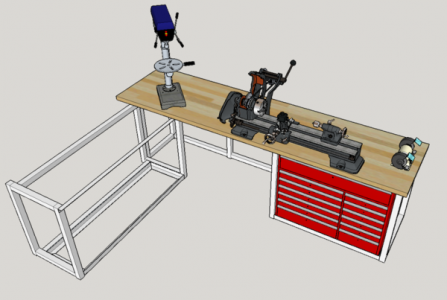

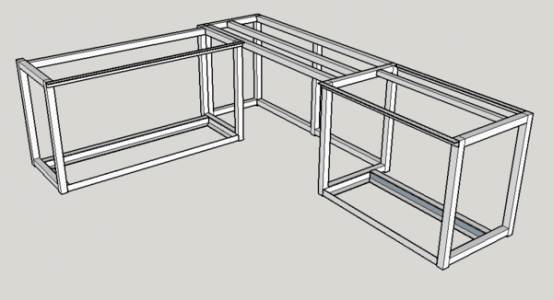

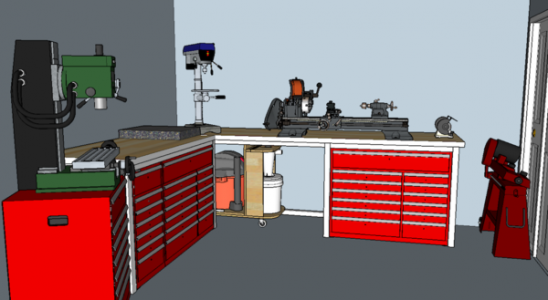

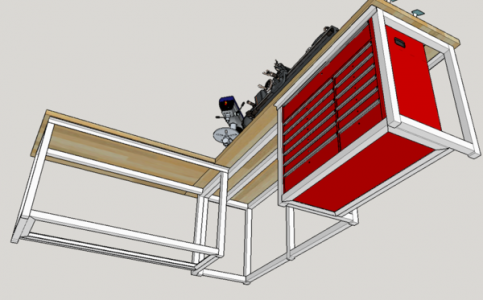

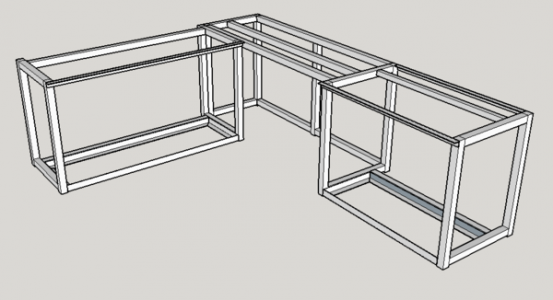

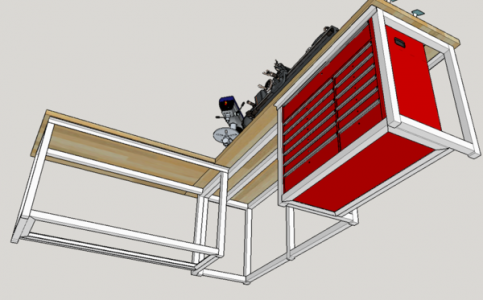

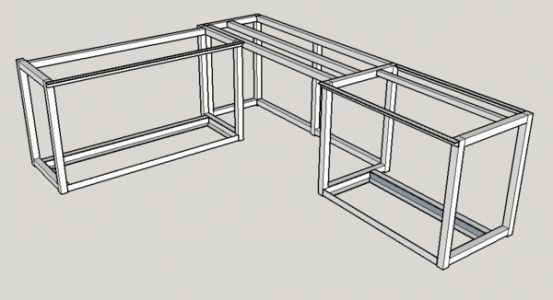

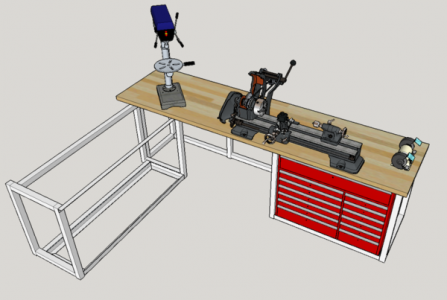

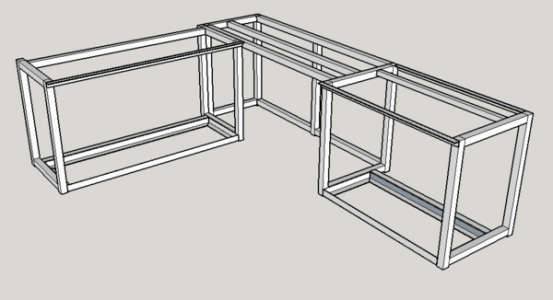

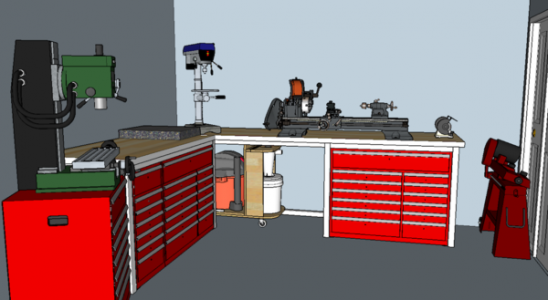

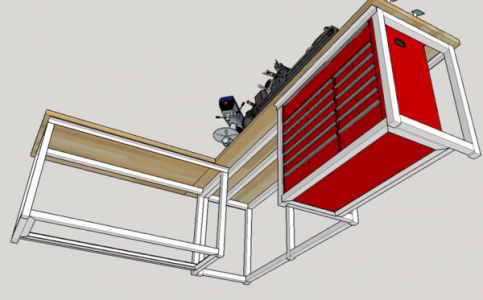

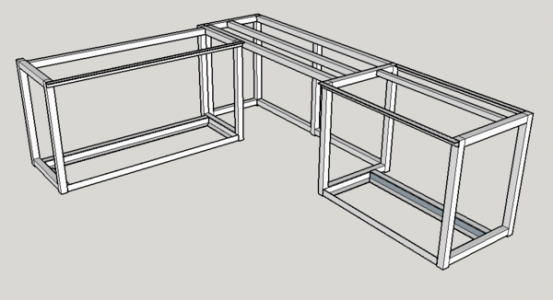

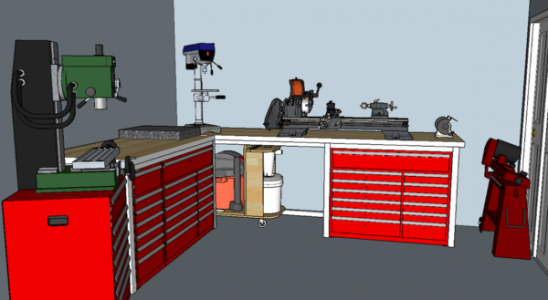

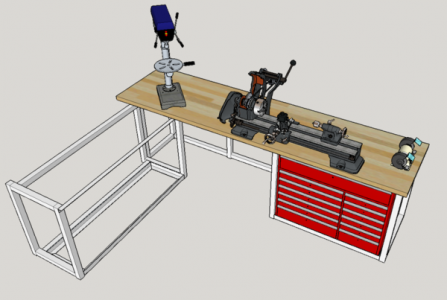

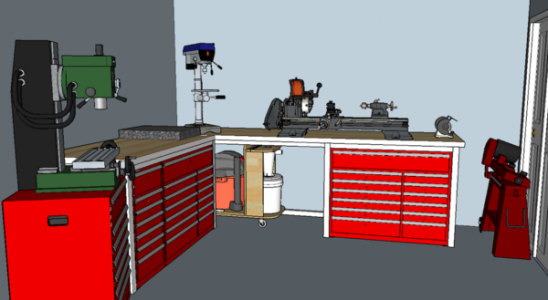

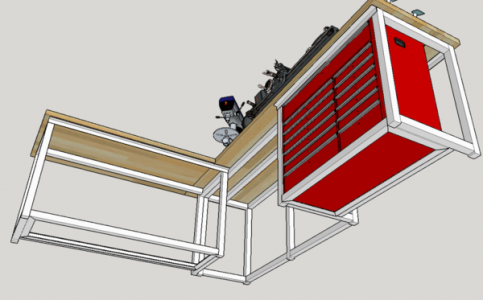

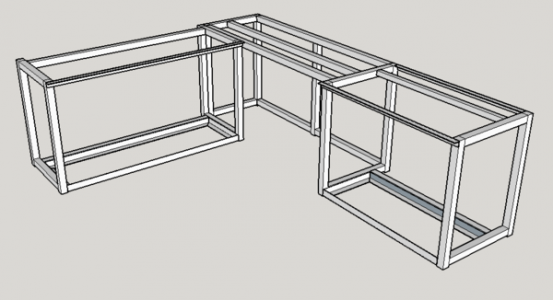

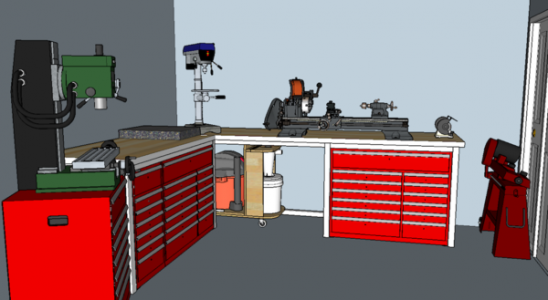

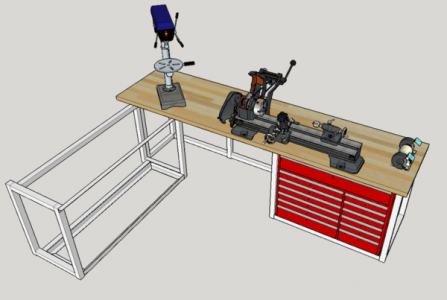

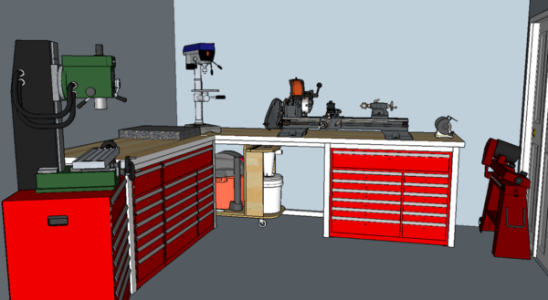

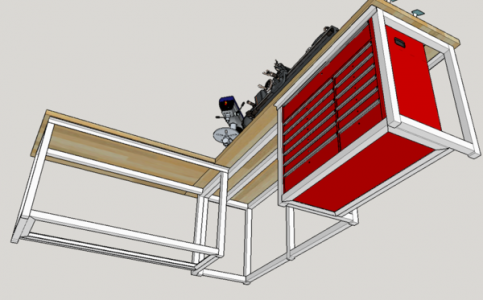

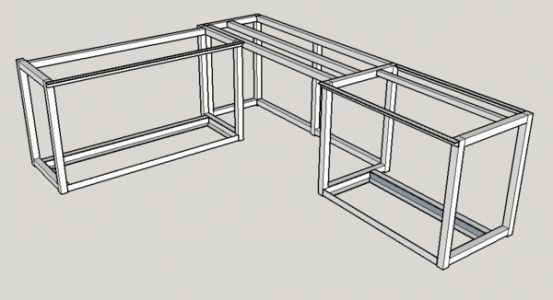

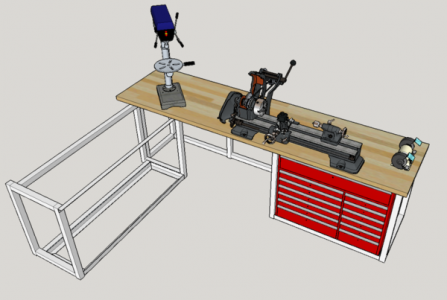

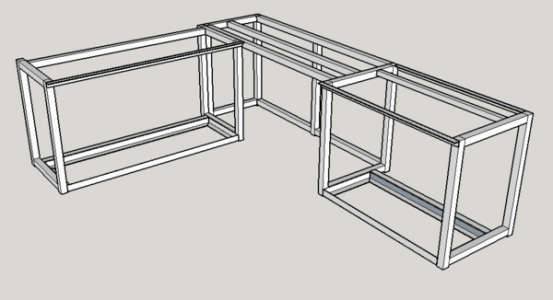

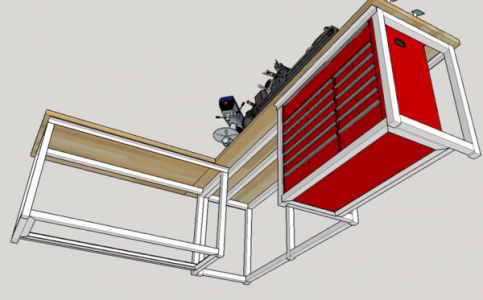

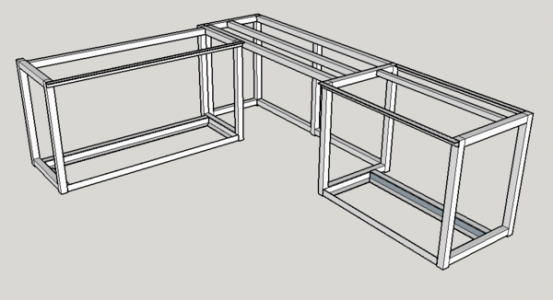

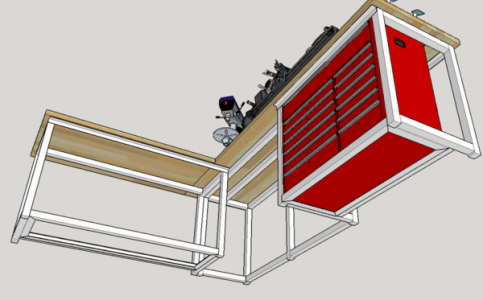

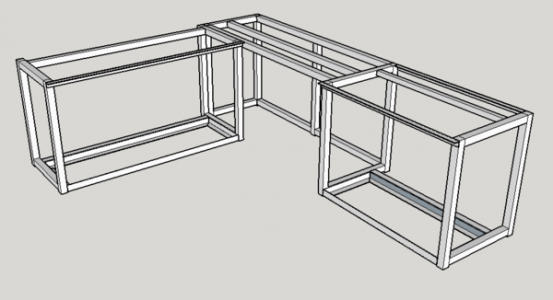

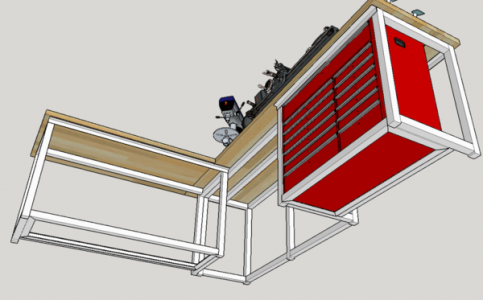

This is the Phase 3 bench:

- I do woodworking, wood turning, auto maintenance, and welding projects in my garage. As well as park my car in there. There's simply no room for more tools!

- I like the notion of climate control for my machine tools since I already have a difficult time keeping my table saw and bandsaw tables rust free. My garage is not climate controlled.

Phase 1: Room prep. I'll paint the ceiling and walls. I'm going to install a 20A recep in the room. The hardwood floor needs refinished, but that almost seems silly when I'm going to be moving in a bunch of heavy machines and getting swarf all over. Instead, I'm considering a floor covering not so different from those floor tiles people put in their fancy garages.

Phase 1.5: Murphy bed. I don't really want to address building the murphy bed right away. It's honestly not a priority project for the build. That said, the bed is in the way... I don't think I'll address this as the second phase, but I'll probably start it while in the middle of Phase 2.

Phase 2: Lathe bench. Tonight I took delivery of a 120" x 30" x 1.75" butcher block maple bench top from Grizzly. It's massive; it's heavy; and it's awesome. I'm beside myself. It's the first purchase I've made for this whole project and I can't wait to get it setup. To do that, I need to fabricate the steel bench to put it on. It's not really a huge project, but it does involve lots of garage time right as it's starting to get super cold. Not my favorite time to be working in the garage. Wrapping up this phase will be my lathe purchase (a South Bend 9A) hopefully in February.

Phase 2.5: Bandsaw/Bench accessories. There's no real building involved with this phase. But the SB 9A has only a 3/4" spindle bore and therefore I'll need a convenient way to turn larger diameter stuff. It seems reasonable that a horizontal bandsaw sets me up well for beginning some turning work. Also included would be a bench grinder for grinding cutting tools- and I'm always on the lookout for a restorable Atlas/South Bend/Walker Turner bench drill press. I don't know if the restoration would be part of this phase or not.

Phase 3: Workbench. This phase will include building the dog leg for the workbench, and purchasing the tool cabinets for the room. This bench is 60" long and serves as an assembly table as well as a convenient place for a surface plate. This might also be a good time to build a workbench into the murphy bed. While the main assembly area will be nice, I'm not convinced that the lack of a toe kick space won't be super annoying. Therefore I'll build a bench into the murphy bed as well that I can pull a chair up to.

Phase 4: Milling machine. This one just has to wait. This project is already going to cost a small fortune. I don't foresee reaching this point at least until next year. But the plan is a PM-25MV or PM-727M mill sitting on top of a Harbor Freight 27" wide cabinet. If I end up getting the heavier mill, I'll enclose the cabinet in a steel frame for better support. Also, I'll likely need to add some blocking in the crawlspace to support this heavier mill.

_______________

Well- that was a lot of words, but I think typing it out helped me solidify some thoughts and build order. Below you can see my plans (to scale) modeled in Google SketchUp. Enjoy!

This is the Phase 2 bench:

This is the Phase 3 bench:

Last edited: