- Joined

- Nov 17, 2012

- Messages

- 48

Hi,

I am a beginner hobby machinist looking to possibly buy a Cincinnati mill.

It seems like a good option for me to start with. And I like the price point!

I know I'll have to do some work to it, but that does not concern me much.

Can anyone tell me about a little about this mill and if you think the price is fair?

He did say he's somewhat flexible on the price.

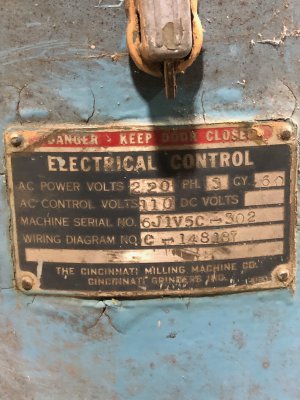

It's a 1HP Cincinnati Mill Serial# 6J1V52-302 asking $1,300 (obo)

I thinks I found some manuals online with variations of 6J1V52.

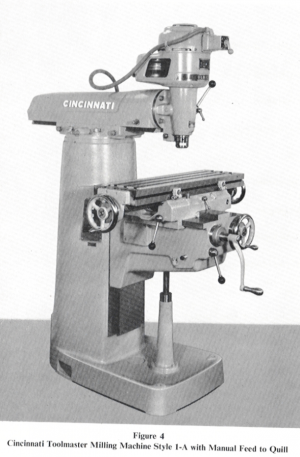

Since there is no power feed I'm thinking it's a type 1-A.

Also not much tooling other than a vice.

Thank you!

Chris

I am a beginner hobby machinist looking to possibly buy a Cincinnati mill.

It seems like a good option for me to start with. And I like the price point!

I know I'll have to do some work to it, but that does not concern me much.

Can anyone tell me about a little about this mill and if you think the price is fair?

He did say he's somewhat flexible on the price.

It's a 1HP Cincinnati Mill Serial# 6J1V52-302 asking $1,300 (obo)

I thinks I found some manuals online with variations of 6J1V52.

Since there is no power feed I'm thinking it's a type 1-A.

Also not much tooling other than a vice.

Thank you!

Chris