If you have a lathe you can easily make yourself bushings for the wheels. If the shaft is not centered well dont dress the wheels as you will mess up the weight distribution by making the wheel itself eccentric.

To be honest I tried this before making this post! Here's a run down on what I tried...

1- Bought good name brand wheels, brand new Nortons from SharpeningSupplies.com

here

2 - Checked run out on grinder shafts. It was very good.

3 - Tried truing up the arbor washers that clamp the wheel since they're only stamped steel. I made an arbor for the lathe and took a facing cut on each side of each washer.

4 - Tried dressing the wheels freehand.

5 - Tried constructing a "field expedient" dressing guide out of aluminum blocks and angles. The idea was to mimic the precise cross travel of a surface grinder style single point dresser. Clamped everything down as parallel as I could then slid the dresser, clamped to a block, across the wheel in a very controlled fashion until it took a cut across the entire wheel.

6 - Attempted to make a closer tolerance bushing on the lathe. The grinder shafts measured about 0.499" or 0.4995". I can't make an ID that accurate with the tools I have. I have no reamers or boring bar that small. The bushing I made ended up about the same or a bit worse than the blue plastic bushings!

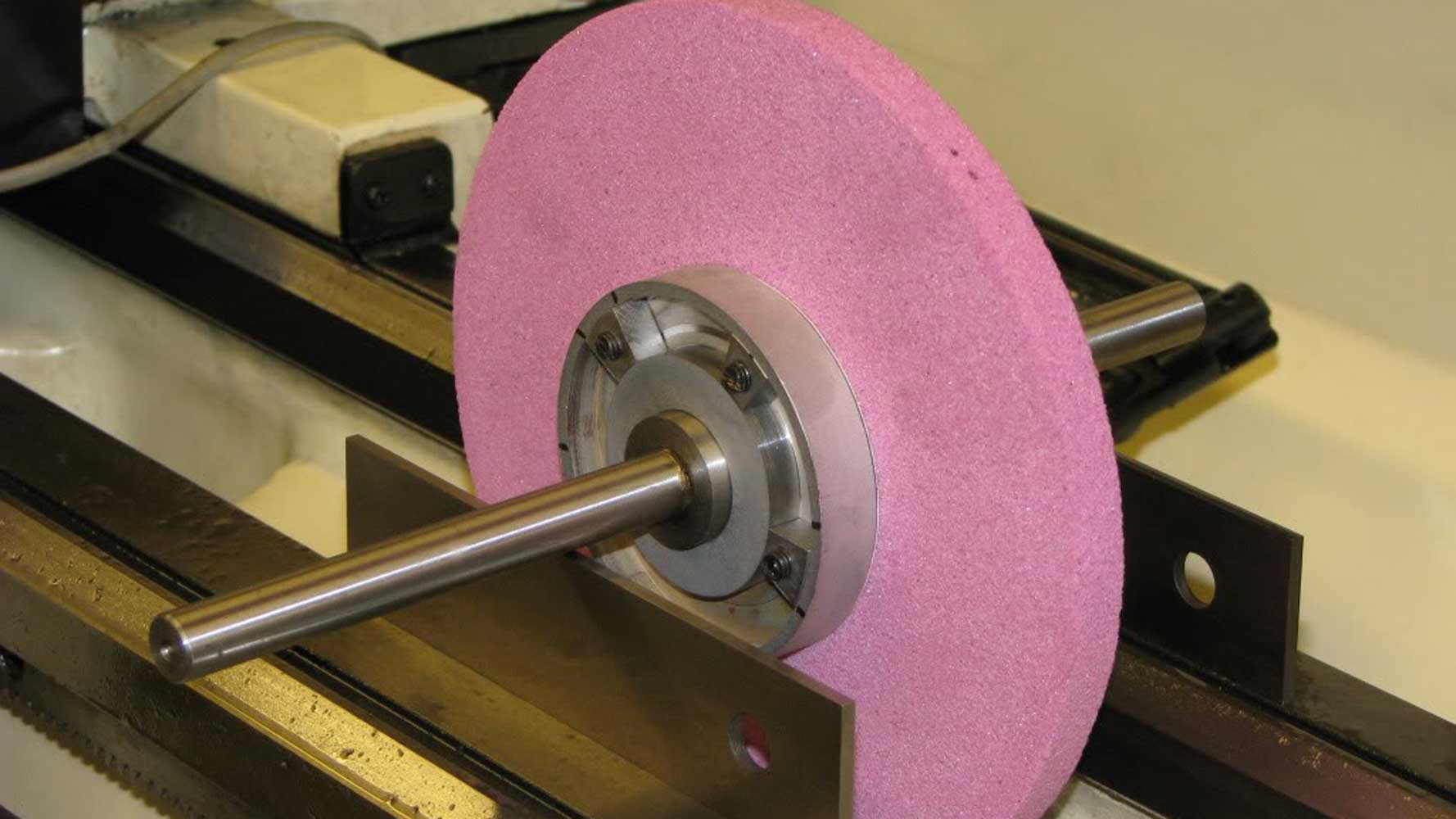

7 - Tried mounting the wheels in the lathe on a custom arbor and using the compound to dress the wheels, holding the dresser in an AXA toolholder.

None of this worked out for me. I am not very experienced with machine work and am mostly self taught so it's very possible that bad practices and poorly made arbors account for my failures. Also as stated by GrayTech, it's likely that I just made the wheels worse each time I tried dressing them.

In any case, it seems like the Oneway kit addresses many of the issues I've experienced. It replaces my stamped steel washers and the plastic bushings with nicely machined parts, and gives me a closely controlled method for balancing the wheel. All this gives me good hope for success. It is kinda pricey but I don't really know what else to try.