- Joined

- Nov 14, 2016

- Messages

- 3,002

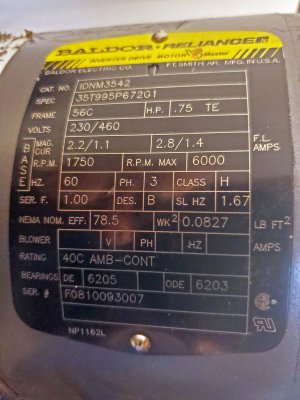

Aaron, what size Baldor are you running. Most Baldors are smooth running. And some are really quite too.

It is a 3/4hp motor. Here is the tag with details

I was very lucky with my mill, the prior owner had it for a few years and got it nicely set up, but then decided he wanted a bigger mill and bought a Bridgeport.

Bridgeport isn't an option for me space wise and the 8520 has been perfect for me.