-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best Quick change for the Mini Lathe

- Thread starter paul_cpu

- Start date

- Joined

- Dec 26, 2016

- Messages

- 2,019

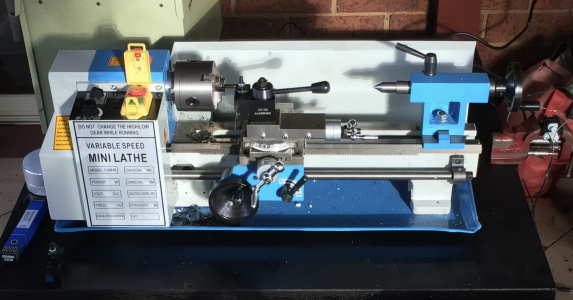

I know looks can be deceiving but that QCTP kit looks like the one from LMS, if the tool post and tool holders clamp tight and there's no slop, then you got a great kit.

Congratulations , that is a solid base to build on.

Congratulations , that is a solid base to build on.

- Joined

- Aug 3, 2020

- Messages

- 103

- Joined

- Jul 31, 2020

- Messages

- 765

In my opinion you have too much parting tool sticking out past the holder, which is part of the reason you are so high. It also will be more likely to chatter and give a bad cut with so much parting tool hanging out. Never have more parting tool hanging out than is strictly needed to cut the thickness you need. You have enough tool hanging out to cut a 3 inch bar, but your workpiece is less than an inch thick. Also be aware of clearance from the tool holder and the chuck. It may mean sliding the part out a very small distance (half inch). But it looks like the part is already far enough out for tool holder clearance in this picture. Roy is right about your tool holder, but, you can make do with the holder you have for small diameters for now.

..see picture

..see picture

Last edited:

- Joined

- Dec 26, 2016

- Messages

- 2,019

Excellent post Roy, nice catch.

Paul, if you search this site you'll find many shop made plans for cut-off tool holders, one of the better one was designed and posted by Mikey, the good news is you can machine it out of Aluminum, I'll look for it and post it here later. now that you have your QCTP set I'm sure you're looking for new projects, this cut-off tool holder would be a good start.

Paul, if you search this site you'll find many shop made plans for cut-off tool holders, one of the better one was designed and posted by Mikey, the good news is you can machine it out of Aluminum, I'll look for it and post it here later. now that you have your QCTP set I'm sure you're looking for new projects, this cut-off tool holder would be a good start.

- Joined

- Dec 26, 2016

- Messages

- 2,019

Here's the blog I'm talking about, it is written by Mikey for his Sherline lathe but it works perfectly with my mini:

And this is the thread where I found it:

www.hobby-machinist.com

www.hobby-machinist.com

Rear-mounted Parting Tool Holder for Sherline Lathe – MachinistBlog.com

www.machinistblog.com

How to Mount Parting Tool

I bought this parting tool but not sure how to use it. Some sites show the tool located behind the stock and some in front of the stock. Which is the right way to mount the tool?

www.hobby-machinist.com

www.hobby-machinist.com

- Joined

- Aug 3, 2020

- Messages

- 103

@adder The photo the tool is literally just sitting there. How ever you make a good point I will re-check this to confirm but I think I tried a bunch of times, but I'll try with the blade closer. I did a fair bit of googling/research and I suspected there was a tool holder that was not on that angle but was unable to 100% confirm. I'll try shortly once the sun comes up.

Even after closing that gap it's still not near the center.

I'll also take a photo of the parting tool holder which is angled up for reference.

@Ken Thank you, yes I need a project. As you can tell I am new, how ever I can feel I am addicted and I am really wanting to make some things...I just don't know what to make.

Even after closing that gap it's still not near the center.

I'll also take a photo of the parting tool holder which is angled up for reference.

@Ken Thank you, yes I need a project. As you can tell I am new, how ever I can feel I am addicted and I am really wanting to make some things...I just don't know what to make.

Last edited: