- Joined

- Oct 14, 2014

- Messages

- 1,976

A little piece of UHMW has worked loose on my apple packing line...

It was bonded to a steel plate and came loose on machine startup (after being shutdown for 10 months). There must be 20 spots like this on the weight sizer and all but this one have held for 30 years.

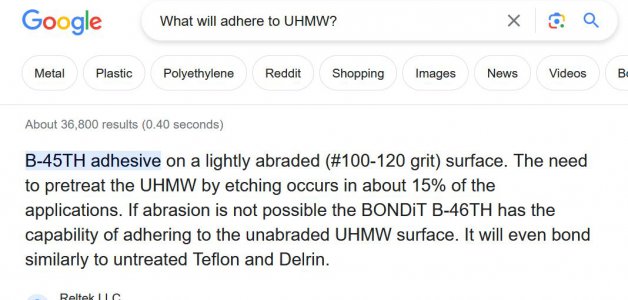

I am getting it clean CLEAN KLEEN! right now. What adhesive would work best?

Karl

It was bonded to a steel plate and came loose on machine startup (after being shutdown for 10 months). There must be 20 spots like this on the weight sizer and all but this one have held for 30 years.

I am getting it clean CLEAN KLEEN! right now. What adhesive would work best?

Karl