The goal is to bore and turn a short length of tubing in a single operation, the tube's wall thickness will be reduced 0.002" or less, split evenly between OD and ID let's say.

I'm thinking my QCTP could do the job but, it doesn't allow two holders to be mounted simultaneously. I think I could "fix" that by cutting or grinding the QCTP holders so they both fit. However, the holders are heat-treated, I'm not sure what I could use to cut or grind them in a reasonably accurate fashion? If it's possible to mount them both, I can devise a way to adjust the outside cutter in order to achieve the desired offset from the inside cutter.

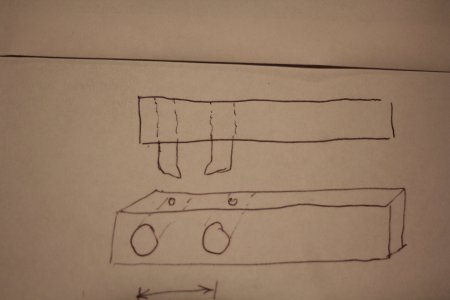

Below is a picture showing what I'm imagining; the boring bar is really an O-ring grooving tool and the turning cutter is not the one I'd use, they're just actors.

Even if it's possible to do this, it may be a bad idea for reasons I've not considered, that I can't find anything on the Internet about doing this is a good indication it might be in the same league as the square wheel .

.

Thoughts? And, thanks!

I'm thinking my QCTP could do the job but, it doesn't allow two holders to be mounted simultaneously. I think I could "fix" that by cutting or grinding the QCTP holders so they both fit. However, the holders are heat-treated, I'm not sure what I could use to cut or grind them in a reasonably accurate fashion? If it's possible to mount them both, I can devise a way to adjust the outside cutter in order to achieve the desired offset from the inside cutter.

Below is a picture showing what I'm imagining; the boring bar is really an O-ring grooving tool and the turning cutter is not the one I'd use, they're just actors.

Even if it's possible to do this, it may be a bad idea for reasons I've not considered, that I can't find anything on the Internet about doing this is a good indication it might be in the same league as the square wheel

Thoughts? And, thanks!

That can be easily done with one holder . More to come after game is over .

That can be easily done with one holder . More to come after game is over .