- Joined

- Jun 8, 2016

- Messages

- 603

I have a simple question, of which the answer might not be simple but here we go;

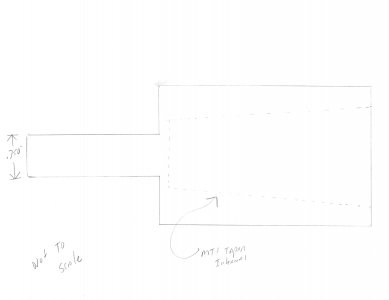

I have a Logan 12" turret lathe with factory turret bored straight at .750". Could I get a MT Reamer, chuck it in a collet or similar in the lathe itself, and then advance the turret to cut a Morse Taper that I could use to hold MT live centers in?

I have a Logan 12" turret lathe with factory turret bored straight at .750". Could I get a MT Reamer, chuck it in a collet or similar in the lathe itself, and then advance the turret to cut a Morse Taper that I could use to hold MT live centers in?