-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boring bar offset

- Thread starter ARC-170

- Start date

- Joined

- Jun 7, 2013

- Messages

- 10,087

Yes, different, they should be on center, too much Chinesium junk out there.

- Joined

- Oct 17, 2018

- Messages

- 922

My other 3 boring bars (different style) or not on center. At least one of them is US-made; the middle one is marked "TH-OBX J.H. WILLIAMS U.S.A. 1/2"

I've looked around and can't tell if other boring bars like the one in my original post are on center.

I wouldn't mind buying a new one; the ones I have are pretty beat up and require really small cutters. I was thinking of getting an insert one, but hesitate because the inserts are so expensive. I don't use a boring ball all the time, but when I need one, I need one.

I've looked around and can't tell if other boring bars like the one in my original post are on center.

I wouldn't mind buying a new one; the ones I have are pretty beat up and require really small cutters. I was thinking of getting an insert one, but hesitate because the inserts are so expensive. I don't use a boring ball all the time, but when I need one, I need one.

- Joined

- Jun 7, 2013

- Messages

- 10,087

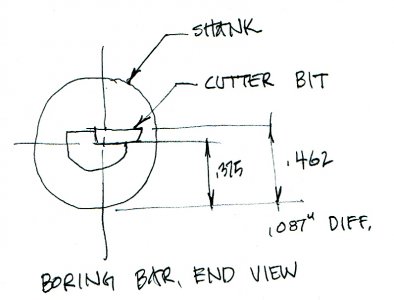

Most all the boring bars that I have seen have the hole for the tool bit broached on center, which requires the bar to be held below center if used in a lathe; if they were broached off center to allow the bar to be used concentric with the hole being bored, it would weaken the bar and also increase the overhang of the tool bit and so reduce its stability in the boring bar. A bit if an accident could rip the bottom of the slot out or deform it. An insert bar gives really the best situation in many cases, as it allows the bar to be centered vertically in the bore with the insert on center for best geometry, and a large diameter boring bar can be used in a somewhat larger bore.My other 3 boring bars (different style) or not on center. At least one of them is US-made; the middle one is marked "TH-OBX J.H. WILLIAMS U.S.A. 1/2"

View attachment 447611

I've looked around and can't tell if other boring bars like the one in my original post are on center.

I wouldn't mind buying a new one; the ones I have are pretty beat up and require really small cutters. I was thinking of getting an insert one, but hesitate because the inserts are so expensive. I don't use a boring ball all the time, but when I need one, I need one.

- Joined

- Dec 20, 2012

- Messages

- 9,422

Actually, the height of the brazed carbide tip doesn't matter when the bar is used on the lathe provided you have enough room in the hole to allow the top of the brazed tip to be about 0.010" above the spindle centerline. This is for lathe use. These bars, when used in a boring head on the mill, do not work well because you can't get their tips on center. If you want the best geometry in a solid bar (not inserted carbide) then buy a set of HSS-cobalt bars from KBC or LMS. Their tips will be ground on center, or get a solid carbide bar from Micro 100, Circle Machine and others.

If cost is an issue then your best shot is to use a HSS-cobalt set from KBC tools or LMS. They will bore almost any hole up to about 2+" deep, they will bore accurately and finish really well. My set from Borite can bore into the tenths so I know they work.

If you want to go with an inserted bar then do some homework. In the long run, you will save money by spending more up front for a solid carbide bar in a size that will accommodate most of the holes you will bore on the lathe. For me, that's a 3/8" bar that will bore almost 4" deep and as big around as my chuck will hold. Look for a SCLCR bar that will accept CCMT or CCGT inserts, which are cheap as dirt. The bars I actually prefer were made by Circle Machine and are now made by Widia but they are more expensive than most of us wish to pay. See if you can find an SCLCR carbide bar by Iscar or one of the more well known makers.

If cost is an issue then your best shot is to use a HSS-cobalt set from KBC tools or LMS. They will bore almost any hole up to about 2+" deep, they will bore accurately and finish really well. My set from Borite can bore into the tenths so I know they work.

If you want to go with an inserted bar then do some homework. In the long run, you will save money by spending more up front for a solid carbide bar in a size that will accommodate most of the holes you will bore on the lathe. For me, that's a 3/8" bar that will bore almost 4" deep and as big around as my chuck will hold. Look for a SCLCR bar that will accept CCMT or CCGT inserts, which are cheap as dirt. The bars I actually prefer were made by Circle Machine and are now made by Widia but they are more expensive than most of us wish to pay. See if you can find an SCLCR carbide bar by Iscar or one of the more well known makers.

- Joined

- Oct 17, 2018

- Messages

- 922

The ones I'm asking about in my original post are for lathe use. I have another set for my mill boring head. I've used them and they worked just fine. I'll need to spend more time using them to really feel like I knew they are working well, though.Actually, the height of the brazed carbide tip doesn't matter when the bar is used on the lathe provided you have enough room in the hole to allow the top of the brazed tip to be about 0.010" above the spindle centerline. This is for lathe use. These bars, when used in a boring head on the mill, do not work well because you can't get their tips on center. If you want the best geometry in a solid bar (not inserted carbide) then buy a set of HSS-cobalt bars from KBC or LMS. Their tips will be ground on center, or get a solid carbide bar from Micro 100, Circle Machine and others.

If cost is an issue then your best shot is to use a HSS-cobalt set from KBC tools or LMS. They will bore almost any hole up to about 2+" deep, they will bore accurately and finish really well. My set from Borite can bore into the tenths so I know they work.

If you want to go with an inserted bar then do some homework. In the long run, you will save money by spending more up front for a solid carbide bar in a size that will accommodate most of the holes you will bore on the lathe. For me, that's a 3/8" bar that will bore almost 4" deep and as big around as my chuck will hold. Look for a SCLCR bar that will accept CCMT or CCGT inserts, which are cheap as dirt. The bars I actually prefer were made by Circle Machine and are now made by Widia but they are more expensive than most of us wish to pay. See if you can find an SCLCR carbide bar by Iscar or one of the more well known makers.

The sets from KBC and LMS don't have any info on where the cutter bit is located. I think I have a set from KBC and another Chinesium one.

What about this one:

https://www.kbctools.com/itemdetail/6-870-062

It's about $50, 6" long, but a smaller dia shank (3/8"). I was thinking I'd like a thicker shank (3/4"). It states the centerline is 1/4"; is this where the cutter is located?

Would I buy just one boring bar, or is it better to buy a few? I'm thinking I'd use one for boring deep (6" or more) holes and another for boring holes in the mid-range (3"-6") and maybe another for shallower holes. Or, could I just use a long one for all the holes and mount it so it only sticks out to the depth needed? I'm leaning towards just one.

They are $26 each at McMaster, about $12 at KBC, and $5-$15 at LMS. Are those reasonably inexpensive? Would you recommend buying them in bulk? I've only used them a few times and I broke the one I was using; good thing it had 3 sides!

Last edited:

- Joined

- Oct 31, 2016

- Messages

- 2,645

I am curious as to what you don't like about your current boring bars. My go to boring bars are like the round ones in the picture in post #4. I don't have the necessary experience to know what is better and will follow this thread to learn more about boring bars.

- Joined

- Oct 17, 2018

- Messages

- 922

The ones in the photo came with a bunch of stuff I got with a lathe I bought for the QCGB. The bits are really small and hard to sharpen. I've used inserts at the adult school machine shop where I occasionally sub and they were really nice, except they are easy to break and expensive. They acquired a whole bunch of 'em free so they can afford to have noobies break them all the time. I bought the ones in my original post and they have worked okay. I didn't know that the offset is different in all of them.I am curious as to what you don't like about your current boring bars. My go to boring bars are like the round ones in the picture in post #4. I don't have the necessary experience to know what is better and will follow this thread to learn more about boring bars.

I'm making a boring bar holder for my Atlas Craftsman lathe and was getting ready to drill the hole in the block when I went down this rabbit hole. I thought the hole would be concentric with the lathe axis, but because the cutter contact point on my existing boring bar set (like in post #1) is above center, the hole will be harder to drill. I was going to put a bit in the lathe chuck and drill into the block so the hole was exactly on the lathe axis, but this won't work. So...I thought I'd look into another boring bar type before I continued my build.

- Joined

- Nov 14, 2020

- Messages

- 1,738