-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boring Bar Setup?

- Thread starter Alaskanrocket

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

@mikey

Sorry, I was not trying to argue. You are a far more experienced machinist than I am, and judging from the quality of your comments, a much better one as well.

It may seem like I am arguing for the sake of an argument, but I am not. In fact, I can't think of a single time I have disagreed with you on a fundamental concept or method for machining, and I have learned plenty from your comments in the past I regard debate as healthy for the community, and especially for the OP. I agree with you 100% that boring a deep and very precise hole requires extra care in tool selection.

I can step up onto an anti-HSS soap box just as easily. HSS has numerous issues of its own.

Please accept my apologies if you have taken offense to anything I have said.

Thank you, Josh. Please accept mine for the tone of my response.

I do respect your feeling that debate is healthy for the forum. I am not in a position to agree or disagree but I would much prefer not to be involved in such debates. Perhaps in the future you can just ignore my comments so that I can feel free to leave them. I will pay you the same courtesy.

As a relative newby, I'm picking up a lot of information here that would be useful. However, I'm not familiar with boring tool geometry as discussed above. Could someone give a quick overview about the considerations when choosing a boring tool and how to use the tool properly. I've used my boring tools on many occasions, but my results have been "inconsistent" to put it mildly. I understand the problems with deflection of the tools as I've experienced this on many occasions, but the use of geometry and different inserts and cutting tools escapes me.

TIA,

Bob

TIA,

Bob

- Joined

- Jun 15, 2013

- Messages

- 1,199

Insert bars usually employ a lay down geometry, where as a turning tool for the od is flat, using the same insert. There are exceptions, my favorite Iscar turning tool, QNMG insert, has a neg 7deg rake, the insert lays down, but the actual insert itself has a sharp up rake at the edge, it cuts really well, it leaves a great finish, that same insert can be used on an Iscar QNMG boring tool.

Different geometries are better for different materials

Different geometries are better for different materials

- Joined

- May 17, 2015

- Messages

- 165

I only own insert bars, not for any prejudice one way or another. I have only just started getting tooling and havent come across hss boring holders. I did fork out on tooling up on the basics to get started and was recommended a quality set and an extra 25mm bar as well. At the time i couldn't afford to buy a boring bar holder for my toolpost ( i dont have a qctp). After trying to shim the boring bars to height and still maintain any rigidity I got the ***** and bought a good holder with multiple sleeves to suit a range of bars. Being in Australia it cost a fortune but it was money well spent. Time saved in stuffing around trying to set up and the ability to adjust the bar out length to suit each job has paid off for me already.

After all that rambling i think my point is, spend money on a boring bar, but make sure you have a good solid and easy to use holder and budget for both. The best bar held in a holder with shims and hss offcuts is still rubish.

After all that rambling i think my point is, spend money on a boring bar, but make sure you have a good solid and easy to use holder and budget for both. The best bar held in a holder with shims and hss offcuts is still rubish.

Last edited by a moderator:

- Joined

- Aug 26, 2013

- Messages

- 1,061

As a relative newby, I'm picking up a lot of information here that would be useful. However, I'm not familiar with boring tool geometry as discussed above. Could someone give a quick overview about the considerations when choosing a boring tool and how to use the tool properly. I've used my boring tools on many occasions, but my results have been "inconsistent" to put it mildly. I understand the problems with deflection of the tools as I've experienced this on many occasions, but the use of geometry and different inserts and cutting tools escapes me.

I'm not exactly sure what you are asking, but I'll give it a shot, and then you can ask additional or clarification questions if you want.

ill use insert tools as examples, but the concept applies to non insert tools as well.

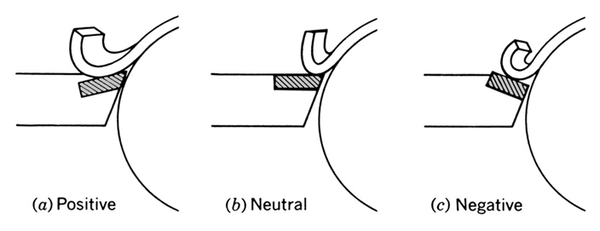

The entire insert can be presented to the cutting surface in one of three ways, positive neutral, or negative.

A positive presentation, increases the back rake on the tool thus reducing cutting forces. The down fall of positive presentation, is the cutting edge is more acute and thus fragile. I've never seen a positive lathe tool, but a lot of face mills work this way. A negative presentation has higher cutting forces, but a much stronger cutting edge. negative tooling is what you will see being run on large production lathes, because edge retention is more important than the hp required to make the cut. A neutral presentation is a compromise between the two, and what you will find in most home shops.

The inserts themselves can have a wide range of presentation angles, as the photo below shows.

Thus, depending on the tool and insert combination you are using, you can get a wide range of back rake angles. everything from negative back rake, to positive back rake approaching 35 or 40 degrees. in a home shop environment where rigidity and hp are low, you want as much positive back rake as you can get in my opinion.

- Joined

- Jul 9, 2014

- Messages

- 613

Tom I think that the sleeve is only there to grip the boring bar so as to stop the clamping nuts marking it and raising up a burr on the bar.

I tried turning up a bar to suit the sleeve and it wasn't until I discovered that it wouldn't fit that I realised the sleeve was not a true round .

I have the same sort of QCTP tool holder , discovered that you need to slide the sleeve out , open it up a smidgeon with a hammer & a thin screwdriver blade and then used threaded bar big washers & nuts to force it back in so it springs outwards against the holder body , it is essential to get the slot on the sleeve in the right position for if it is as shown in the picture it becomes very difficult to grip the boring bar .., silicone greasing the nuts , screws , insert & rotating the insert so the slot is at 10 o'clock at the end shown allows for a much easier tightening up.

Some boring bars may also need a sliver of aluminium coke can between the sleeve & the tool to get a good fit because of the ovality I've mentioned.

I also had to get some much stronger high tensile steel Allen cap machine screws as the one of those that came with the holder sheared under very little pressure .

In fact I've replaced all the clamp screws on all the various tool holders for sound engineering practice

- Joined

- Aug 26, 2013

- Messages

- 1,061

I think that the sleeve is only there to grip the boring bar so as to stop the clamping nuts marking it and raising up a burr on the bar.

The sleeve is there, so that the holder works for more than one size bar. For an AXA sized QCTP, they make two holder sizes. The larger one is 1" and has a sleeve that lets you also use 3/4" boring bars. The smaller one is 3/4" with a 5/8" sleeve.

I have the same sort of QCTP tool holder , discovered that you need to slide the sleeve out , open it up a smidgeon with a hammer & a thin screwdriver blade and then used threaded bar big washers & nuts to force it back in so it springs outwards against the holder body , it is essential to get the slot on the sleeve in the right position for if it is as shown in the picture it becomes very difficult to grip the boring bar .

You probably should have sent that thing back, because it was defective. If the sleeve is properly made, it should slide on without to much struggle.

as you can see here, you can make your own sleeves if needed. I've made sleeves for 1/2" and 3/8" bars to fit a 3/4" holder.

http://www.dans-hobbies.com/2008/10/09/boring-bar-sleeve/

Last edited: