Which way to install the nuts wouldn't be an issue if you used two nuts of the same thickness.

Which, to be honest, is what I've done in the last few years because of my peculiar zinc arrangement.

Which way to install the nuts wouldn't be an issue if you used two nuts of the same thickness.

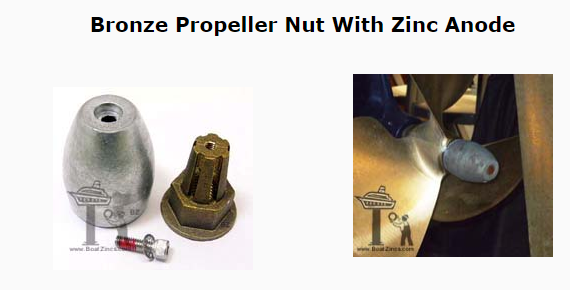

Other than the crazy price they get for them why not just use a "C" size prop nut and zinc? It's 3/4-10 thread. Typically the shaft is drilled for a cotter pin. View attachment 259535

http://www.boatzincs.com/prop_nut_s...MIkoCp8e6_2QIVxiSBCh1BtwX7EAQYASABEgL24PD_BwE

You shoulda 'R'TLDR

To stick three nuts together, drill two of them out to remove threads, then assemble on threaded rod with one more nut to hold them together. TIG weld with silicon bronze filler.

I was on my phone having lunch in a fast food joint. I should go back and read now that I'm on my laptop. Thanks for the props. I'm not the most skilled machinist around, but I seem to have a knack for seeing simple solutions to complex problems. Maybe because I'm just lazy.You shoulda 'R'

OP used hex rod, turned as much of the length down that he needed to and drilled and tapped (which makes sense as the simplest, most elegant way of getting the part he wanted).

Turns out he was a better machinist than he thought he was, so props to him and props to him for updating the thead too; it was a good read (including the posts where the OP very politely dismisses an apparent blowhard claiming authority).

And props to you for carefully and closely reading the OPs post and spotting that not all of the part's bore needed to be threaded (thus the thread removal to deal with the nuts not lining up when on the threaded rod); I love it when I see a question answered properly, it's kinda rare on the internet these days.

If you ever answer a question I've asked, I'm going to look at your suggestion first.

Wish there were more people on the internet with the motivation to ensure their answer is actually relevant to the problem in hand.

'Lazy' like a fox mate.I was on my phone having lunch in a fast food joint. I should go back and read now that I'm on my laptop. Thanks for the props. I'm not the most skilled machinist around, but I seem to have a knack for seeing simple solutions to complex problems. Maybe because I'm just lazy.