- Joined

- Mar 19, 2014

- Messages

- 2,681

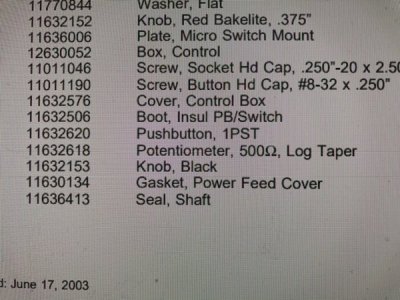

Are you saying you have a linear pot? My memory tells me that pot should have a logarithmic taper resistance. Was there anything wrong with the original pot? I would use the original pot if nothing is wrong with it and it is just used, a used pot is fine by me. The original pot was also sealed. That kind of pot with mentioned characteristics, design and made in the USA is kinda hard to find today and $. Use the original whenever possible.What's horrible is that there just isn't much too it after the board. I've got new micro-switches. Which I've taken out and tested to insure they work properly. Then set the switches to not over run each other on the direction handle...neutral and so forth. The fuse holder is new. The light is new. The pot is new. I thoroughly tested the pot today. It works fine. I even tried testing it in the balanced state. About 250 ohms each side. Very Even. The motor is basically brand new inside except for the field windings. But that was done professionally. I don't think that would be wrong. Power switch works or the light wouldn't work. Wiring wise it's all exactly as diagrams show me. Down to the pin on the harness everything connects to.

Tomorrow I'll go over every wire in the harness and check for faults there. Grounded and/or no continuity from ends to pins.Beyond that I'm back to it being an expensive mystery. If I can't find it I'll have to call Wayne at icai and ask him what he thinks. Maybe it will be obvious to him.

Know anyone that is great at electronics?

Paul

Last edited: