- Joined

- Aug 4, 2023

- Messages

- 78

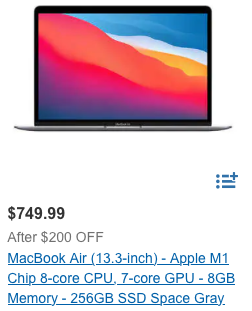

No my wife is a professional photographer so she had to have the newest bestest thing. But i only paid $1700 for the mill. A few hundred more for a bunch of tooling and stock. And a few hundred in rentals for transporting. All in $2800Ok, you can get a new MacBook for around $1,000 (or less), so you got all this for less than a grand???