- Joined

- Sep 8, 2019

- Messages

- 4,392

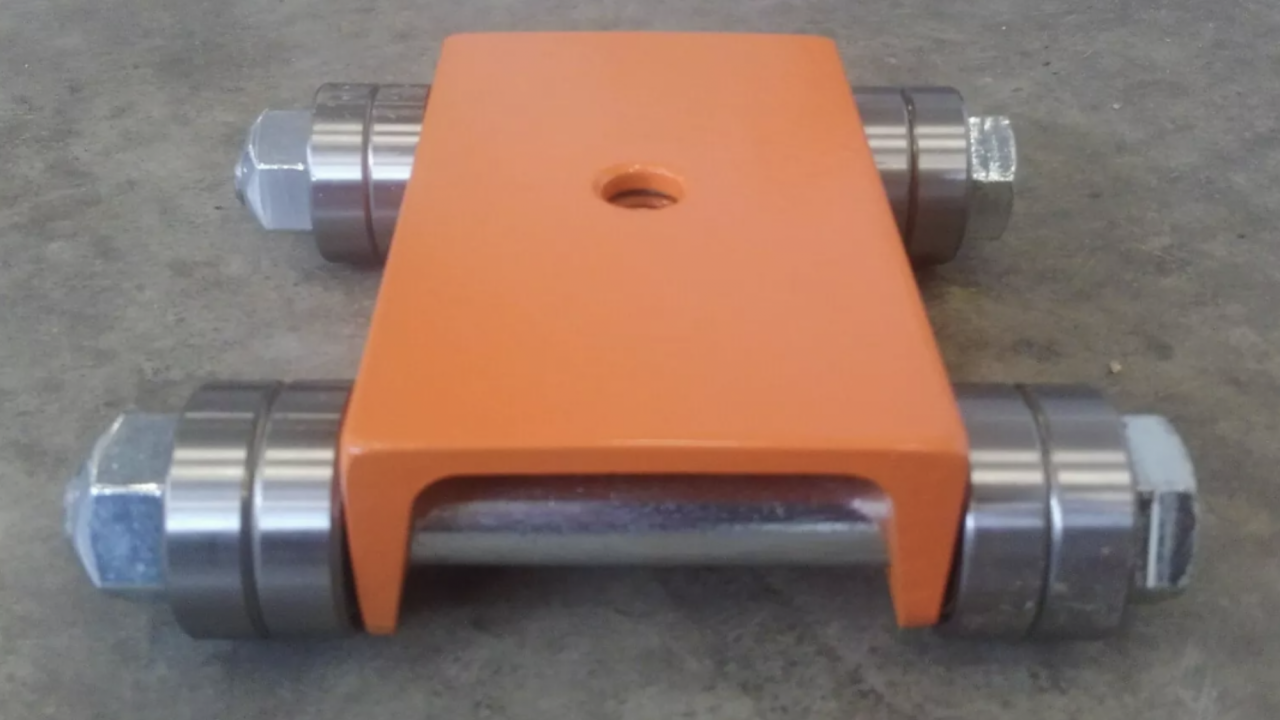

Here are some pictures of a skate, & knee mills & engine lathes on skates:

The last drawing makes me cringe, and amazed that it comes from factory instructions. One wrong move and the sling under the mounting boss for a slotting attachment would slip right off the end. I'd at least put a stout pin through the hole to trap the sling. Kind of a sharp edge in that area as well. If you use a lift eye threaded into the top of the ram, shoot for 1-1/2 diameters of thread engagement, and use a good quality lift eye, not some made in PRC POS. Spending the extra $$ on a USA made Crosby is cheap insurance. Do yourself a favor and use purpose built slings, and not rope. Those drawings look like they came from "the good old days"!

So maybe it is not the best idea to hang a $15K machine by a $7 eye bolt?The last drawing makes me cringe, and amazed that it comes from factory instructions. One wrong move and the sling under the mounting boss for a slotting attachment would slip right off the end. I'd at least put a stout pin through the hole to trap the sling. Kind of a sharp edge in that area as well. If you use a lift eye threaded into the top of the ram, shoot for 1-1/2 diameters of thread engagement, and use a good quality lift eye, not some made in PRC POS. Spending the extra $$ on a USA made Crosby is cheap insurance. Do yourself a favor and use purpose built slings, and not rope. Those drawings look like they came from "the good old days"!

No room for a gantry crane. Also, I don’t have help. My Dad is turning 80 years old, & my one son & two grandsons in the house are *very* reluctant to help; the young people in the house are very much doing their own thing.Well, You definitely have a big job in front of you. You probably mentioned it at some point but do you have room for a gantry crane in your shop?

Do you have any help with this move or are you relaying only on the rigging crew?

With at least one other person a toe jack and skates you should be able to move your mill and lathe around. That my option anyway.

I can't say that I have ever needed a toe jack before, but I wanted to be as safe as possible when I moved my mill. I will probably use it again later to lift it and add some sort of spacer under it to raise it up 4 or 5".

What a humongous forklift!