- Joined

- Jun 26, 2013

- Messages

- 191

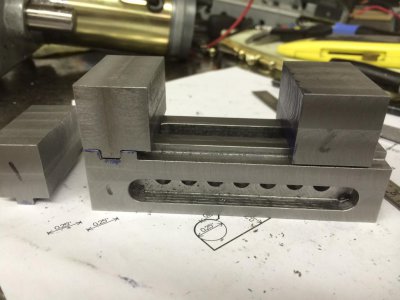

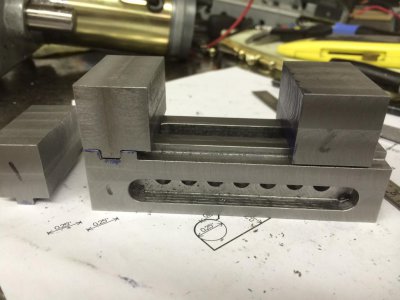

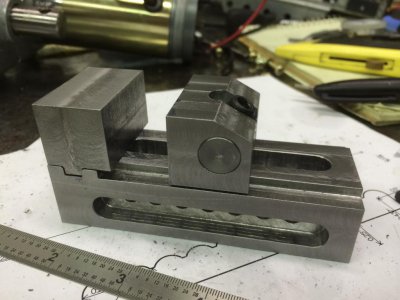

I remade the fixed jaw...

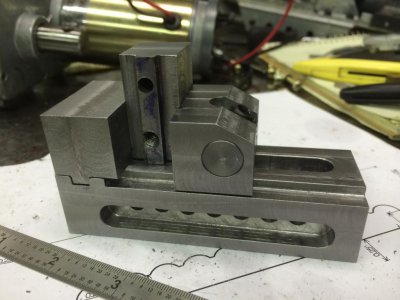

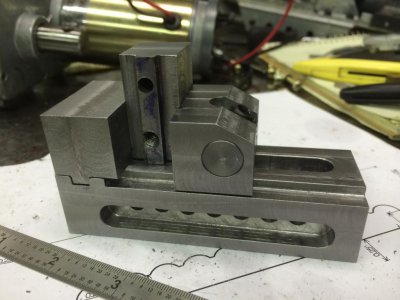

Then turned to the movable jaw...

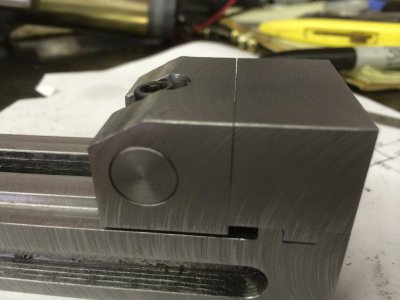

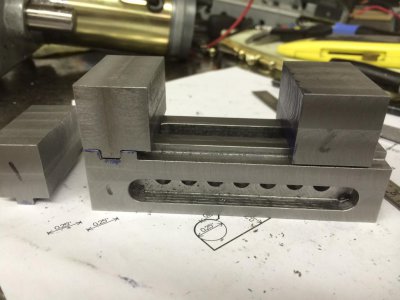

Made the thing the movable jaw pulls against this afternoon:

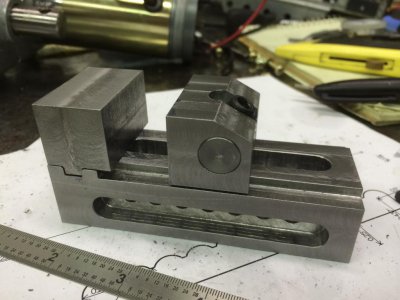

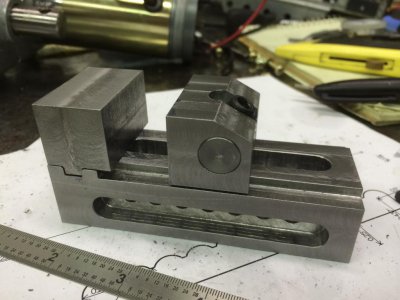

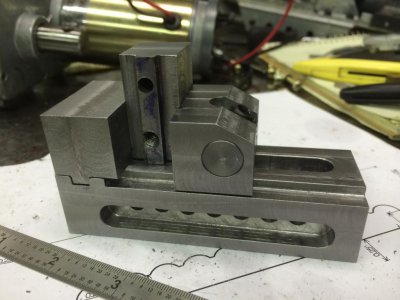

At this point it's basically complete:

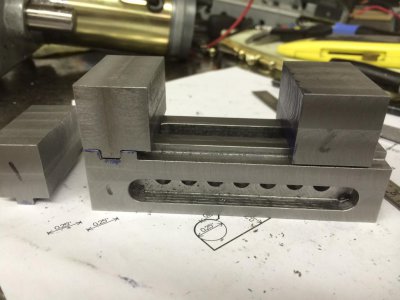

And even works:

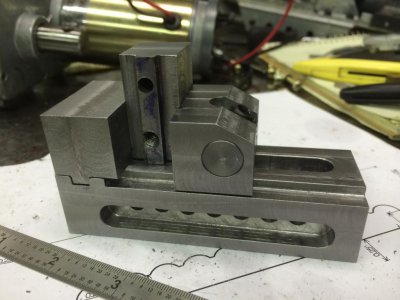

Plans for the next steps are to fly cut the top, sides and end to make all the edges on the separate pieces as smooth as possible. Then to bevel a slight undercut on the inside bottom edges of the jaws so I can run a mill across the faces of the jaws to try to get them as flat and true as I can. Then finally a couple of grooves on the movable jaw to help hold round stock...

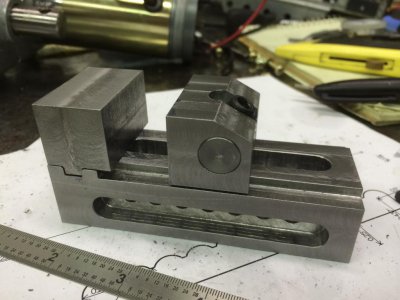

Almost there...

Then turned to the movable jaw...

Made the thing the movable jaw pulls against this afternoon:

At this point it's basically complete:

And even works:

Plans for the next steps are to fly cut the top, sides and end to make all the edges on the separate pieces as smooth as possible. Then to bevel a slight undercut on the inside bottom edges of the jaws so I can run a mill across the faces of the jaws to try to get them as flat and true as I can. Then finally a couple of grooves on the movable jaw to help hold round stock...

Almost there...