- Joined

- Dec 13, 2012

- Messages

- 466

the KDKs are nice and sleek. don't see them much around.

edit: is that piston or wedge driven?

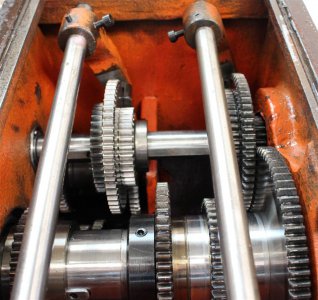

You had asked about the KDK a while ago but I don't think I explained it right, so Here are a couple of pictures.

This one is open waiting for a holder.

This is the clamping action. You can see it uniformly tightens in the dovetail drawing the holder against the tool post.

The dowel sticking out is for the height adjustment. There is a set screw in each older the set the height.

Gary